Alaskan: I suggest keeping a close eye on the hi-pressure lines, esp. the one from the pump to the membrane. 800+ psi can make for a lot of pulsing and vibration and chafe. Probably preaching to the choir here, but suggest securing with cushion-clamps to timber structure. Avoid using cable-ties and contact with cables and other hoses. Leakage while commisioning or general use will almost certainly result in sea water on the "floor". Anything down there that might object to a swim?

The high pressure lines create a lot of vibration, as does the actual membrane assembly. If you mount the membrane or the HP lines to something that creates a sounding board effect, you'll have a WHOLE lot of noise when you run the system. It's something that's easily and most always overlooked. The response is "it's a watermaker, they make noise", which doesn't have to be.

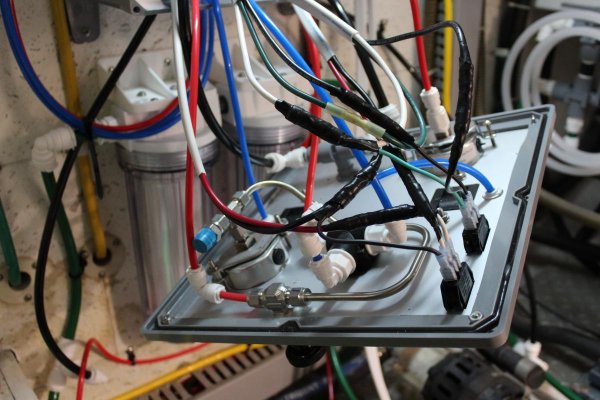

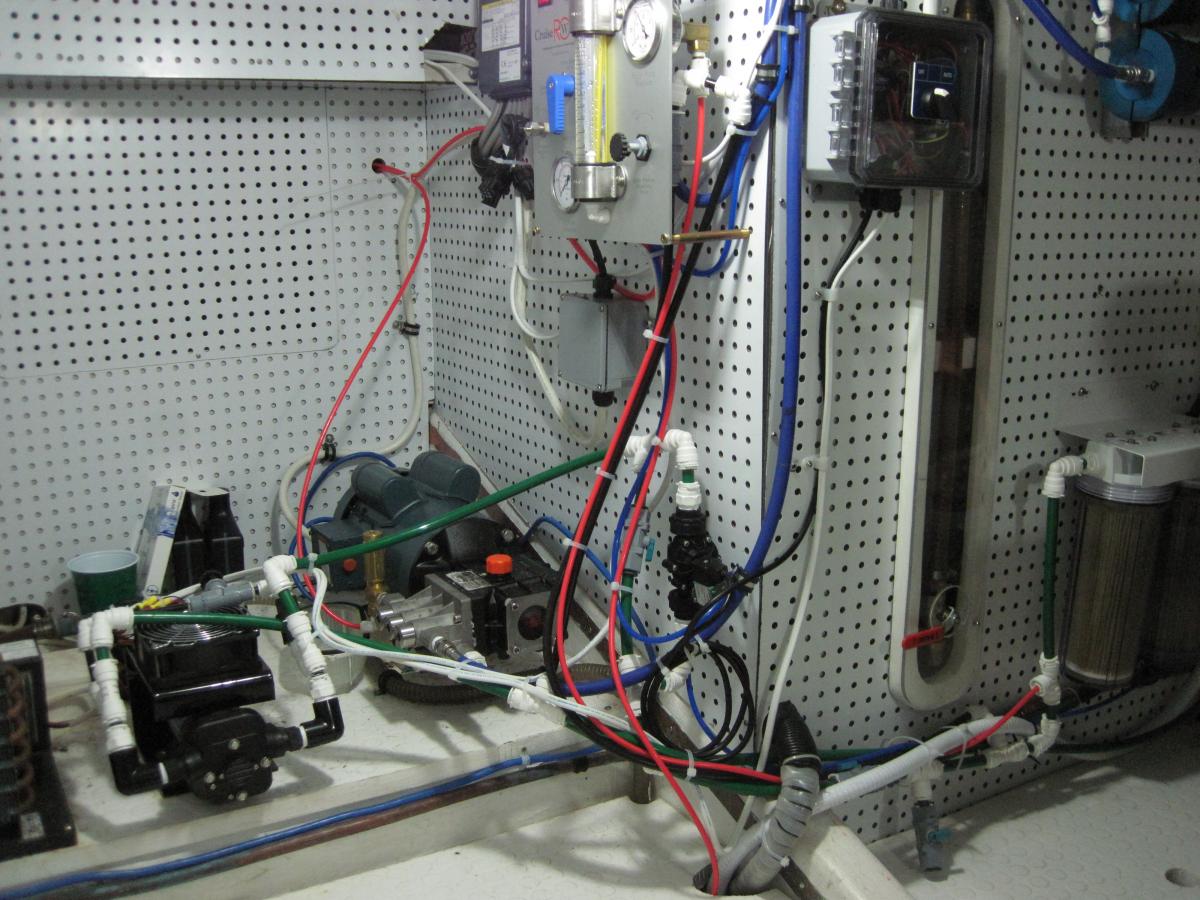

Use vibration isolators on the HP pump, and secure the HP hoses with vibration isolating mounts. It also helps to use vibration isolators on membrane mountings. The reduction in transmitted noise can be dramatic. An inexpensive vibration mount can be fabricated from silicone hose (top photo). The commercial vibration isolators I used in the (lower) photo are mounted on shear, (photo is looking up) it takes a mount rated for that service. These folks have a wide selection, have used them in the past.

AAC - Anti Vibration Shock Mounts - Cylindrical Base Spring Rubber Sorbothane Neoprene

Vibration control is not hard to implement, not terribly expensive, and makes a HUGE, HUGE difference in the end result. If you have a noisey watermaker, add some of the silicone hose gizmos to the HP hoses and see if it doesn't quiet it down!

A bit late to the party, but create an air gap in your supply to the tank. Top fill is best. Second choice would be tee into a vent near the tank. A solid connection can create a siphon in mysterious ways, it can create a path for chlorinated dockside water in the tank to get to the membranes and damage them.

As another poster mentioned, NO BRASS fittings in contact with seawater. Recipe for failure!

The second membrane lasted over 5 years with heavy use. We replaced it when the TDS was approaching 500ppm. We cruise in mostly warm climates.

The second membrane lasted over 5 years with heavy use. We replaced it when the TDS was approaching 500ppm. We cruise in mostly warm climates. The second membrane lasted over 5 years with heavy use. We replaced it when the TDS was approaching 500ppm. We cruise in mostly warm climates.

The second membrane lasted over 5 years with heavy use. We replaced it when the TDS was approaching 500ppm. We cruise in mostly warm climates.