mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,234

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

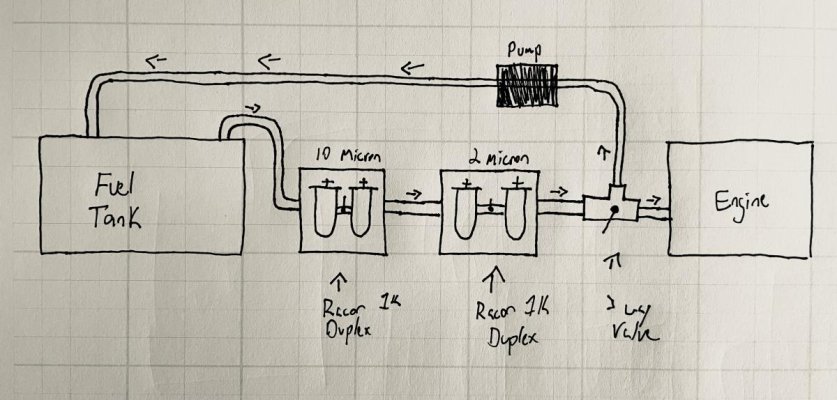

A polishing system is nice. You will end up with a lot valves and while you may decrease your chance of dirty fuel clogging your system, you increase the chance of human error starving your system.West coast. From Alaska to Mexico. Not all in one trip, but setting the boat up to be able to head to those areas.

Having run the Pacific from Alaska to Mexico dozens of times on dozens of boats, I think a pair of Racor 1000's is perfectly sufficient. Carry a case of extra filters. Use the size recommended by your engine manufacturer vs the armchair wisdom to install 2-micron filters in your Racors.

Best defense is to use your boat. This will improve your tactical knowledge about the boat and turnover fuel. And get you comfortable. Will do more than any polishing system ever could.

Peter