Is there any coating which will seal out the water from a teak deck short of painting it? Would Cetol or varnish seal off any small leaks or gaps in the caulking? Are there any other products that might work? I'm after a short term 1 season solution. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Waterproofing teak decks

- Thread starter Rosco2018

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

SteveK

Guru

- Joined

- Jul 5, 2019

- Messages

- 5,077

- Location

- Gulf Isalnds BC canada

- Vessel Name

- Sea Sanctuary

- Vessel Make

- Bayliner 4588

Captain Tully was introduced to me. It may be too early to be sure but I can attest that several areas around windows for instance that weeped have stopped.

I would not suggest using on teak deck due to cost, and also that I think teak deck leaks are not from fillable cracks which this product addresses.

My teak deck is original and on inspection where visible underneath there are no signs of leaks. But my decks were part of the original construction built on top of a wood plywood deck. That process involved (as I read) spreading a layer of sealant and bedding the teak which was then held in place by nails, perhaps ribbed nails until sealant bound/glued to deck.

The newer glass boats with teak were not bedded but just screwed down thus water can travel under it and where these screws allow, leaks follow. Also glass boat decks may not be supported as much as the glass is strong enough even though it flexes. It is that flex which loosens the screws, I think, which then creates a leak trail. JMO, but I did stay at a holiday inn express once upon a time.

It is no wonder that many suggest removal to make the permanent repair.

I would not suggest using on teak deck due to cost, and also that I think teak deck leaks are not from fillable cracks which this product addresses.

My teak deck is original and on inspection where visible underneath there are no signs of leaks. But my decks were part of the original construction built on top of a wood plywood deck. That process involved (as I read) spreading a layer of sealant and bedding the teak which was then held in place by nails, perhaps ribbed nails until sealant bound/glued to deck.

The newer glass boats with teak were not bedded but just screwed down thus water can travel under it and where these screws allow, leaks follow. Also glass boat decks may not be supported as much as the glass is strong enough even though it flexes. It is that flex which loosens the screws, I think, which then creates a leak trail. JMO, but I did stay at a holiday inn express once upon a time.

It is no wonder that many suggest removal to make the permanent repair.

Xsbank

Guru

- Joined

- Sep 7, 2013

- Messages

- 3,791

- Location

- Canada

- Vessel Name

- Gwaii Haanas

- Vessel Make

- Custom Aluminum 52

Sorry but even screwed-down teak decks on GBs were bedded.

The best way to find leaks is to wet the dry deck with a hose and watch it dry again. Leaking seams will stay wet after the rest dries. Mark the leaks, then you have to reef out the sealant between the planks and re-seal the seams. If you have not been diligent in cleaning them, i.e. using salt water only and a soft brush across the grain, you will get a lot of the softer wood being removed and the deck will be rough, requiring sanding. Bleaches and treatments remove that same soft wood and beg to be sanded. This removes a layer of teak and the bungs that cover the screws will be too thin or fall out; if the screws are stainless, the bungs and the immediate area around them will be stained black by the "stainless" screws. You will need to pick out the remaining bung, remove the screw and drill it down some more, replace the screw (usually pulling it will damage the head - I used silicon bronze so no more staining) and new screws, new glue, new bungs that will need to be cut flush and the tops sanded. Perimeter caulking and under the 1/4 round around the house need to be bedded too. Make sure the sealant gets in the screw holes. This process takes time and if you don't do it yourself, paying a yard to do this is very spendy. I used to do my GB32 at anchor, everyone and the dog got shooed off the boat for 2 hours while I lay on the deck and did a patch. Eventually I did it all. I've stated my method on here before.

Sanding, "teak treatments," bleaches and stiff brushes will all kill your teak decks. Teak naturally turns grey in the sun and any method of stopping that requires removing a layer of wood which will thin and eventually ruin the deck and require its removal and/or replacement.

New teak decks are just glued but the wood is the same, just use salt water and a soft brush or prepare to replace it much sooner.

Covering your deck with a product does a couple of things: first, coated teak can be slippery when wet. Uncontested teak never is; you have now committed yourself to redoing the coating, more often than just washing the plain teak; if you do any repairs required, you will have to remove the product first, likely; most products attack the seam caulking. Because teak decks are "organic" which means alive, they will flex and contract and expand (why the seam sealer is a type of rubber) coatings will fail and allow water in anyway.

The best solution, if your decks have worn out or failed, is to remove the teak, remove the top layer of 'glass, remove any rotten plywood sub - core, replace the plywood, re-glass the plywood and put a finish coat of glass with a textured anti-skid top. Remember you will need a stronger base as the teak added a measure of strength to the deck. $$$ unless you do it.

Sanding and treatments do look good for a while but if you come across a boat where the decks look like new teak, a significant amount of the finite thickness of your decks has been sanded off, gone forever.

Don't sand teak decks!!

The best way to find leaks is to wet the dry deck with a hose and watch it dry again. Leaking seams will stay wet after the rest dries. Mark the leaks, then you have to reef out the sealant between the planks and re-seal the seams. If you have not been diligent in cleaning them, i.e. using salt water only and a soft brush across the grain, you will get a lot of the softer wood being removed and the deck will be rough, requiring sanding. Bleaches and treatments remove that same soft wood and beg to be sanded. This removes a layer of teak and the bungs that cover the screws will be too thin or fall out; if the screws are stainless, the bungs and the immediate area around them will be stained black by the "stainless" screws. You will need to pick out the remaining bung, remove the screw and drill it down some more, replace the screw (usually pulling it will damage the head - I used silicon bronze so no more staining) and new screws, new glue, new bungs that will need to be cut flush and the tops sanded. Perimeter caulking and under the 1/4 round around the house need to be bedded too. Make sure the sealant gets in the screw holes. This process takes time and if you don't do it yourself, paying a yard to do this is very spendy. I used to do my GB32 at anchor, everyone and the dog got shooed off the boat for 2 hours while I lay on the deck and did a patch. Eventually I did it all. I've stated my method on here before.

Sanding, "teak treatments," bleaches and stiff brushes will all kill your teak decks. Teak naturally turns grey in the sun and any method of stopping that requires removing a layer of wood which will thin and eventually ruin the deck and require its removal and/or replacement.

New teak decks are just glued but the wood is the same, just use salt water and a soft brush or prepare to replace it much sooner.

Covering your deck with a product does a couple of things: first, coated teak can be slippery when wet. Uncontested teak never is; you have now committed yourself to redoing the coating, more often than just washing the plain teak; if you do any repairs required, you will have to remove the product first, likely; most products attack the seam caulking. Because teak decks are "organic" which means alive, they will flex and contract and expand (why the seam sealer is a type of rubber) coatings will fail and allow water in anyway.

The best solution, if your decks have worn out or failed, is to remove the teak, remove the top layer of 'glass, remove any rotten plywood sub - core, replace the plywood, re-glass the plywood and put a finish coat of glass with a textured anti-skid top. Remember you will need a stronger base as the teak added a measure of strength to the deck. $$$ unless you do it.

Sanding and treatments do look good for a while but if you come across a boat where the decks look like new teak, a significant amount of the finite thickness of your decks has been sanded off, gone forever.

Don't sand teak decks!!

Last edited:

SteveK

Guru

- Joined

- Jul 5, 2019

- Messages

- 5,077

- Location

- Gulf Isalnds BC canada

- Vessel Name

- Sea Sanctuary

- Vessel Make

- Bayliner 4588

Xsbank, don't be sorry. your opinion matters.

I still maintain that decks that leak are from flexing of the deck and thus creating a loose screw or nail depending on what was used and flexing the caulk between boards to allowing water to weep.

I still maintain that decks that leak are from flexing of the deck and thus creating a loose screw or nail depending on what was used and flexing the caulk between boards to allowing water to weep.

Giggitoni

Guru

- Joined

- Jun 21, 2008

- Messages

- 2,092

- Location

- United States

- Vessel Name

- Mahalo Moi

- Vessel Make

- 1986 Grand Banks 42 Classic

Sorry but even screwed-down teak decks on GBs were bedded.

The best way to find leaks is to wet the dry deck with a hose and watch it dry again. Leaking seams will stay wet after the rest dries. Mark the leaks, then you have to reef out the sealant between the planks and re-seal the seams. If you have not been diligent in cleaning them, i.e. using salt water only and a soft brush across the grain, you will get a lot of the softer wood being removed and the deck will be rough, requiring sanding. Bleaches and treatments remove that same soft wood and beg to be sanded. This removes a layer of teak and the bungs that cover the screws will be too thin or fall out; if the screws are stainless, the bungs and the immediate area around them will be stained black by the "stainless" screws. You will need to pick out the remaining bung, remove the screw and drill it down some more, replace the screw (usually pulling it will damage the head - I used silicon bronze so no more staining) and new screws, new glue, new bungs that will need to be cut flush and the tops sanded. Perimeter caulking and under the 1/4 round around the house need to be bedded too. Make sure the sealant gets in the screw holes. This process takes time and if you don't do it yourself, paying a yard to do this is very spendy. I used to do my GB32 at anchor, everyone and the dog got shooed off the boat for 2 hours while I lay on the deck and did a patch. Eventually I did it all. I've stated my method on here before.

Sanding, "teak treatments," bleaches and stiff brushes will all kill your teak decks. Teak naturally turns grey in the sun and any method of stopping that requires removing a layer of wood which will thin and eventually ruin the deck and require its removal and/or replacement.

New teak decks are just glued but the wood is the same, just use salt water and a soft brush or prepare to replace it much sooner.

Covering your deck with a product does a couple of things: first, coated teak can be slippery when wet. Uncontested teak never is; you have now committed yourself to redoing the coating, more often than just washing the plain teak; if you do any repairs required, you will have to remove the product first, likely; most products attack the seam caulking. Because teak decks are "organic" which means alive, they will flex and contract and expand (why the seam sealer is a type of rubber) coatings will fail and allow water in anyway.

The best solution, if your decks have worn out or failed, is to remove the teak, remove the top layer of 'glass, remove any rotten plywood sub - core, replace the plywood, re-glass the plywood and put a finish coat of glass with a textured anti-skid top. Remember you will need a stronger base as the teak added a measure of strength to the deck. $$$ unless you do it.

Sanding and treatments do look good for a while but if you come across a boat where the decks look like new teak, a significant amount of the finite thickness of your decks has been sanded off, gone forever.

Don't sand teak decks!!

^ this!!!!

Teak decks actually need minimal time for maintenance unless they have been treated with various teak "killers". Keep the seams and bungs in good shape and learn to enjoy and appreciate grey.

jgwinks

Guru

I saw one where they covered the teak with pickup truck bed coating and ran it up the sides a few inches. Didn't look very good, but stopped the leaks. You could still see the teak plank outlines through the coating, it would have looked a lot better if they had put in on thicker to cover the pattern or stripped the teak off first. I don't think any kind of varnish or finish is going to do much to waterproof it.

Nomad Willy

Guru

Teak decks only need good caulking to be waterproof. Teak being so oily needs nothing but a little oil added from time to time. And keeping the deck out of the sun like in covered moorage would probably help.

And any “film” coating will peel off rather soon as basically nothing adheres to the oily teak.

And any “film” coating will peel off rather soon as basically nothing adheres to the oily teak.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,296

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Really the only way to waterproof them is to remove the teak and fiberglass the deck or coat it with bedliner. The bedliner isn’t beautiful but it will work. PMM had an article in it years ago about doing it. The owner liked it and said it did solve all the leaking issues. I spoke to him years later and he said it was holding up very well. Removing the teak and glassing the decks is the most common method but if you have it done it is very expensive. If you DIY it is a lot of work but not rocket science. Recaulking will help slow the leaks if the caulk is going bad but the leaks will keep coming back. Good luck.

C lectric

Guru

The person who did the bedliner coating is a member here.

charles is his moniker. Full name is Charles C. Cullota,Jr.

He did an in depth report for Passagemaker as Commodave mentions and also wrote up a bunch for Trawler Forum.

I will leave it to you to do a search though. You may still be able to contact him through a PM from T.F.

https://www.trawlerforum.com/forums/members/charles-2710.html

charles is his moniker. Full name is Charles C. Cullota,Jr.

He did an in depth report for Passagemaker as Commodave mentions and also wrote up a bunch for Trawler Forum.

I will leave it to you to do a search though. You may still be able to contact him through a PM from T.F.

https://www.trawlerforum.com/forums/members/charles-2710.html

Pete Meisinger

Guru

- Joined

- Oct 7, 2012

- Messages

- 3,145

- Location

- USA

- Vessel Name

- Best Alternative

- Vessel Make

- 36 Albin Aft Cabin

The simple answer is "Nope". Paint it or rip it out.

pete

pete

STB

Guru

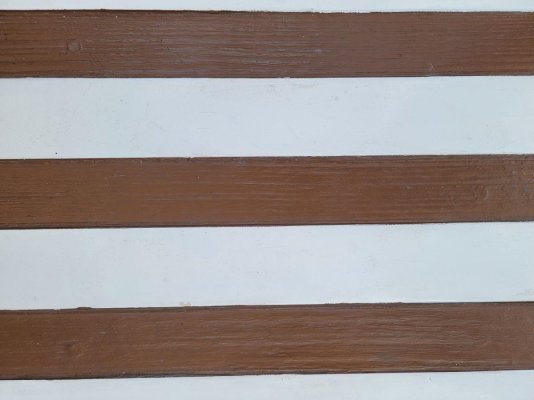

I recently did some insets with 4 coats of the stuff below, 6 in areas where water pools (hoping to raise them a bit to avoid pooling).

https://www.amazon.com/dp/B07PDHTMVX/ref=cm_sw_r_em_apa_i_xVq.Fb13P6Z35?psc=1

It hasn't been long enough to say how it lasts, but it is water proof and leak sealing, went on like a dream, has good traction, left the real teak looking like realistic vinyl teak, and cleans up easily with a hose with the usual sprayer set for a forceful spray.

I did it to reduce maintenance, improve traction, and prevent the need for more sanding which will eventually reduce the teak to veneer. I didn't have a leak or loose problem, so I can't comment about how well it works for water problems.

For aesthetic reasons I, personally, may not have used it on more than insets as there would be no black lines (unless, I guess, painted those either on top or 1st). But, it did cover over all of the old sealant, etc.

My only prep was a powerful, gas-powered commercial pressure washing (washer rented from home depot). I did not prime, and starting mid-morning after the dew burned off, I was able to get 4 costs in in one day. Put on in a Florida November, it was "seemingly dry" within about an hour. Basically, I pressure washed over the weekend, let it dry for days until I got the chance, then taped it off one day and did all 4 coats the next.

So far it has had furniture dragged across it, hooks and poles poked at it, things dropped on it, a hurricane, etc, with no signs of damage. But years of the sun will be the real test.

Acetone will eat into it slowly, dulling it after a while, and then, if allowed to sit, softening it as it sinks in. At least it did when it was fairly new (I tested, as acetone is a common solvent in my world). It cleans up with water initially, then acetone, then over about a week it gets hard to remove, even with acetone (but, I never tested it after long enough for acetone soaking in not to hurt it, if that ever happens).

It touches up really well and none of my tape pulled any up.

I don't have any good photos, but have attached a few that show it by chance. Please ignore all of the bird droppings...sorry about those!

It passes the 60 day test with "like new" performance.

https://www.amazon.com/dp/B07PDHTMVX/ref=cm_sw_r_em_apa_i_xVq.Fb13P6Z35?psc=1

It hasn't been long enough to say how it lasts, but it is water proof and leak sealing, went on like a dream, has good traction, left the real teak looking like realistic vinyl teak, and cleans up easily with a hose with the usual sprayer set for a forceful spray.

I did it to reduce maintenance, improve traction, and prevent the need for more sanding which will eventually reduce the teak to veneer. I didn't have a leak or loose problem, so I can't comment about how well it works for water problems.

For aesthetic reasons I, personally, may not have used it on more than insets as there would be no black lines (unless, I guess, painted those either on top or 1st). But, it did cover over all of the old sealant, etc.

My only prep was a powerful, gas-powered commercial pressure washing (washer rented from home depot). I did not prime, and starting mid-morning after the dew burned off, I was able to get 4 costs in in one day. Put on in a Florida November, it was "seemingly dry" within about an hour. Basically, I pressure washed over the weekend, let it dry for days until I got the chance, then taped it off one day and did all 4 coats the next.

So far it has had furniture dragged across it, hooks and poles poked at it, things dropped on it, a hurricane, etc, with no signs of damage. But years of the sun will be the real test.

Acetone will eat into it slowly, dulling it after a while, and then, if allowed to sit, softening it as it sinks in. At least it did when it was fairly new (I tested, as acetone is a common solvent in my world). It cleans up with water initially, then acetone, then over about a week it gets hard to remove, even with acetone (but, I never tested it after long enough for acetone soaking in not to hurt it, if that ever happens).

It touches up really well and none of my tape pulled any up.

I don't have any good photos, but have attached a few that show it by chance. Please ignore all of the bird droppings...sorry about those!

It passes the 60 day test with "like new" performance.

Attachments

Last edited:

Rosco2018

Veteran Member

https://liquidrubber.ca/products/polyurethane-deck-coating?variant=16096721207398

That is very interesting. What color and texture do you think might match an old teak deck? Misty Grey or Neutral Beige? Smooth or Textured?

FYI I have a 1974 Grand Banks 32, one of the very first fibreglass ones, hull stamp # GNDB05301074

That is very interesting. What color and texture do you think might match an old teak deck? Misty Grey or Neutral Beige? Smooth or Textured?

FYI I have a 1974 Grand Banks 32, one of the very first fibreglass ones, hull stamp # GNDB05301074

STB

Guru

I used the "Smooth Saddle Brown". It is supposed to match the Benjamin Moore color of the same name (2164-10), if you want to get a chip locally.

Even the smooth is non-slip. They told me the textured was really intended for steps treads and more industrial applications.

Also, from reading reviews, most people who put down textured on decks and docks put a couple of coats of smooth over it to fill in and reduce the texture.

So, the choice really seemed to be smooth or both, not smooth or just textured for cosmetic reasons and to ease cleaning.

And in my case, I wanted to keep the wood look, and textured could have been less wood like.

They tell me it'll last indefinitely and that it lasts for "years and years and years" until worn through or physically damaged, that the sun won't kill it 1st. But, if I get 3-5 years out of it before needing to refresh, and I can do that without going down to the wood, I won big time, I think. As you can tell, I've been happy with the 2 month test -- but so far it has only been 2 months.

Even the smooth is non-slip. They told me the textured was really intended for steps treads and more industrial applications.

Also, from reading reviews, most people who put down textured on decks and docks put a couple of coats of smooth over it to fill in and reduce the texture.

So, the choice really seemed to be smooth or both, not smooth or just textured for cosmetic reasons and to ease cleaning.

And in my case, I wanted to keep the wood look, and textured could have been less wood like.

They tell me it'll last indefinitely and that it lasts for "years and years and years" until worn through or physically damaged, that the sun won't kill it 1st. But, if I get 3-5 years out of it before needing to refresh, and I can do that without going down to the wood, I won big time, I think. As you can tell, I've been happy with the 2 month test -- but so far it has only been 2 months.

North Baltic sea

Guru

Hi,

I am grateful for how a modern way of Nordic Tug built teak decks on my tug. With zero screws, zero leakage, they are glued tightly to the grp cover and yet really in great condition and beautifully installed, like everything in this brand has a quality that lasts for use.

NBs

I am grateful for how a modern way of Nordic Tug built teak decks on my tug. With zero screws, zero leakage, they are glued tightly to the grp cover and yet really in great condition and beautifully installed, like everything in this brand has a quality that lasts for use.

NBs

I used the "Smooth Saddle Brown". It is supposed to match the Benjamin Moore color of the same name (2164-10), if you want to get a chip locally.

Even the smooth is non-slip. They told me the textured was really intended for steps treads and more industrial applications.

Also, from reading reviews, most people who put down textured on decks and docks put a couple of coats of smooth over it to fill in and reduce the texture.

So, the choice really seemed to be smooth or both, not smooth or just textured for cosmetic reasons and to ease cleaning.

And in my case, I wanted to keep the wood look, and textured could have been less wood like.

They tell me it'll last indefinitely and that it lasts for "years and years and years" until worn through or physically damaged, that the sun won't kill it 1st. But, if I get 3-5 years out of it before needing to refresh, and I can do that without going down to the wood, I won big time, I think. As you can tell, I've been happy with the 2 month test -- but so far it has only been 2 months.

How has it held up over time?

RT Firefly

Enigma

Greetings,

Mr./Ms. J. Welcome aboard.

Mr./Ms. J. Welcome aboard.

STB

Guru

How has it held up over time?

Give me a day or two and I'll post some current photos.

It looks like there are some earlier ones in the thread above to compare then and now.

According to my maintenance log I applied 4 coats November 5, 2020 and it is still going strong. There are no signs of thinning or cracking or powdering or peeling or anything else undesirable.

As I sit here now and think about it, I think the color may have darkened a little bit over time and may now have less of a redish brown tone than it did then -- but maybe I should wash it or am misremembering. The photos will tell the story.

Some temporary boat neighbors were up there looking it over in detail last week and were impressed with it and asking about it. They didn't realize it was as old as it was.

They thouhht it was recently done.

There are a couple of small places where I damaged it (dripped Interlux Perfection on it) and I was able to clean it off with Acetone and then touch it up nearly perfectly if not perfectly by buying one of their tiny sample containers and using that.

It is an important note that I used it on my flybridge -- which is under a bimini. So, although it is outdoors and not enclosed, it is shaded and gets some protection from the rain and doesn't get salt water as the bow of a boat might.

The person who did the bedliner coating is a member here.

charles is his moniker. Full name is Charles C. Cullota,Jr.

He did an in depth report for Passagemaker as Commodave mentions and also wrote up a bunch for Trawler Forum.

I will leave it to you to do a search though. You may still be able to contact him through a PM from T.F.

https://www.trawlerforum.com/forums/members/charles-2710.html

I talked to him last winter. He said his waterproofing worked perfectly up to the time he sold the boat ten years later. The bedliner product he used is called Durabak.

It’s available in a clear version now, which is what we used on our decks. Looks great and so far so good. Even if it just buys us a few years before we have to take more permanent measures, it will have been well worth it.

Last edited:

STB

Guru

Hi all,

Here are photos from today. They can be compared to the earlier above in the thread.

Out of curiosity, I, yesterday, painted a couple of short stripes between the settee and ladder and took a close up showing them next to the earlier painted stripes. I don't know whether the color difference develops in a week a month or over 3 years. I don't think it is just a dye lot thing, because it aligns with my memory. I think it a minor change in any case, but worth noting.

When looking at the photos note that there are two close ups. The one with three stripes shows the new and original side-by-side. The one with just two stripes is just a random part of the deck with all original.

Sorry I didn't wash the deck first. Just got back from a trip and tied up.

-Greg

Here are photos from today. They can be compared to the earlier above in the thread.

Out of curiosity, I, yesterday, painted a couple of short stripes between the settee and ladder and took a close up showing them next to the earlier painted stripes. I don't know whether the color difference develops in a week a month or over 3 years. I don't think it is just a dye lot thing, because it aligns with my memory. I think it a minor change in any case, but worth noting.

When looking at the photos note that there are two close ups. The one with three stripes shows the new and original side-by-side. The one with just two stripes is just a random part of the deck with all original.

Sorry I didn't wash the deck first. Just got back from a trip and tied up.

-Greg

Attachments

Last edited:

I was going to recommend Durabak clear as well. I think this product started with military vessels-very hardy. I did this to the cockpit of my Krogen Manatee. It went on thick and covered the gaps nicely. When it rained the first time, I took the grandest fall imaginable. I promptly added another coat and used a seasoning container to add white sand to the wet Durabak. Worked great for five years before water got underneath at the edges and started to lift it. Hard to caulk the edge at the fiberglass/teak.