We took 2 months this summer with our new to us Tolly 43. All went well EXCEPT

We took 2 months this summer with our new to us Tolly 43. All went well EXCEPT

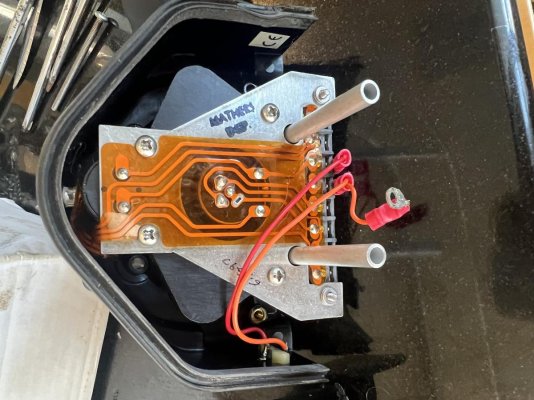

Several times we lost control of our engines .. shifts and throttles, apparently due to malfunction of our Mathers controls.

I have since learned that these issues are common and well known. Engines can suddenly, with no warning, shift gears or go to high throttle extreme. This happened at least five times. Once this caused me to lose control during landing and damage my boat and the adjacent boat.

Mechanics in Canada and Anacortes worked on the problem and diagnosed battery issues .. replacing the starboard alternator. They told me (and I have since learned this is true, that low battery or high voltage could both cause dysfunction.

Getting back home, Seattle, I now learn this is a well known issue with mathers and not just Mathers and not just the old one.

Maintenance for these things is poorly described

The newer units have error codes but ONLY on the engine not at the bridge

T

he newer units do have an alrm to alert that ther eis a malfunction!

The install should include a voltage device that automatically selcts which batter has the best voltage.

Here are some facts.

1. Our controls are old, probably installed in the mid-nineties. Our engine date from 2006 so the controls must have been reinstalled then.

2. We have two stations, one on the FB, one below.

3. On these occasions I have

-lost control of the stbd engine.

-had stbd engine reve to max

-had one engine go into reverse

We took 2 months this summer with our new to us Tolly 43. All went well EXCEPT

We took 2 months this summer with our new to us Tolly 43. All went well EXCEPT The newer units have error codes but ONLY on the engine not at the bridge

The newer units have error codes but ONLY on the engine not at the bridge