Thanks for your detailed response Frosty

Here are some images of the fridge.

Thank you! It's good to see it. Some general info here, but skip down to just below the line of asterisks for the stuff about the problem.

So you and I both have the same controller unit, the 101N0500. I don't know when that one first came out, but my refrigerator is 2015 vintage and has it. Another friend has the same exact fridge as me but 2020 vintage, and it has the newer 101N0510 (with which you can use certain electronic thermostats; otherwise I think it's similar).

So anyway, yours is not an ancient one and looks familiar to me.

The two red flag terminals at the very top are your incoming AC wires (110/220).

Then there is a break and then a bunch of terminals down below. The top ones are the DC + and DC - that are bringing in the power (apparently with a voltage issue at the moment, which these control boxes are very sensitive to).

Next down, F, is the negative lead for the fan that comes on the compressor, and the positive is above on one of the + terminals (skinny wires).

Next down, I believe A and C are for the light in the fridge.

Next down, D is where your flashing diagnostic light hooks up (the other lead goes to the + terminal)

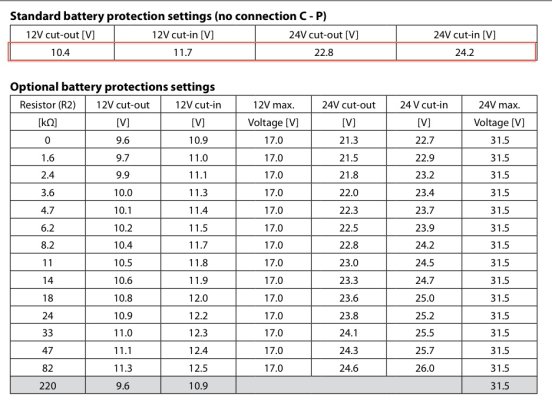

Next, C and T are where the thermostat hooks up (the resistor is on T typically although I don't see it or Waeco may have put it somewhere else on the same line. OR, if there isn't one, your fridge may always be running at the lowest RPM - maybe not best in your climate).

P I think used to have a resistor that had something to do with low voltage battery protect cutout, but a fellow at Secop (Danfoss) told me that is now built in somehow so you may not see anything there.

One difference between yours and mine is that you have the style with the "fence" of condenser coils wrapping around whereas mine has a small "radiator" the same size as the fan. So just two ways of doing the same thing. Then the black "ball" is the actual compressor.

Side note is that I can't tell if this is the case or not, but as important as good insulation, is trying to set it up so that the warm air the fan sends out, cannot then be sucked in again by the fan (vicious cycle of hot air). I can't really tell how yours fares that way. The style of mine is more one long line vs. a wraparound, so it was not too hard for me to make some septums so nary the twain shall meet.

In case you were wondering

But on to the problem:

**************************************************************************************

**************************************************************************************

Your reply mentioned 5 red flashes.

My post said one red flash every 5 secs.

This may have led you down the wrong path in regards to the fault.

Thank you for pointing that out! Geez, that'll teach me to rush.

The good news is one flash is probably much less dire than five, and more fixable by you. Yay. As mentioned above these electronic control units are super sensitive about voltage (or you could say, about avoiding voltage drop).

So what they say for one flash is "low voltage reaching the compressor."

Here are Penguin's steps:

1 Flash Low Voltage

There is insufficient voltage reaching the fridge compressor.

a) Confirm the wire dimension is correct

If this is a new installation check the wire sizing [added by me: you can check the sizes and lengths as mentioned in previous post. The basic guideline is 8AWG max 20 meters; 10AWG max 12 meters; 12 AWG 8 meters.

This also assumes good connections, clean power (nothing else that's going to affect it on same circuit), etc.]

b) Test the Power supply

To properly test the power supply to a Danfoss powered 12v or 24v system, the following testing procedure must be carried out. This will establish whether the power supply feeding the system is free of bad, loose and/or high-resistance connections.

Reading the voltage on the panel or at the batteries is meaningless, as is the fact of a new installation or new batteries. Size and the capacity of the battery bank is irrelevant.

1. Turn off the breaker (or remove the fuse) supplying DC power to the system. 2. Unplug one of the thermostat leads at the controller. 3. Using a multi-meter, read the DC voltage at the battery terminal(s). 4. Connect the multi-meter reading DC voltage to the power terminals (+ and -)

on the controller so that it can be left connected and monitored. 5. Turn on the breaker (or install the fuse) to the system. 6. Check that the voltage is the same as the voltage seen at the battery

terminals. 7. Whilst watching the multi-meter, reconnect the thermostat lead and monitor

the voltage continuously before, during, and after the compressor starts or attempts to start.

Interpreting power supply results

If the power supply is free of loose, bad, and/or high resistance connections, the voltage reading at 5 above will stay very stable and only drop slightly when the compressor starts. As a general rule, on a 12v system the reading should not drop below 12v. If, when the compressor attempts to start, the voltage reading drops significantly, a bad electrical connection should be suspected. If the voltage drop is sufficient to fall below the 10.5v (23v) cut-off built in to the controller, the compressor will stop. (At this point the voltage may return to it s original reading.) The fan or pump will continue to run for approx. 45 seconds and then the compressor will attempt a re-start. If the voltage is then above 11.5v (23.5v) the compressor will start or attempt to re-start again.

WARNING If the multi-meter being used is a digital model that is slow to react, the voltage may drop below 10.5v (23v) and then recover too quickly to register on the meter. This can lead to the situation where the compressor starts then stops from low voltage, the voltage returns to its original value, and there being no significant drop on the meter.

If the compressor starts and runs OK but stops after a short while, the voltage may be gradually dropping towards and below the 10.5v (23v) cut-off point. This should be easily identified on the meter. If the nature of the fault is such that the voltage reading at 5 above drops below 10.5v (23v) even before the compressor attempts to start, a very bad electrical connection must be suspected. This is because even the small load of the fan or pump relay, both less than 0.5 amp (0.25 amp), is seemingly sufficient to reduce the voltage considerably.

What to look for A loose and/or high-resistance connection can be anywhere in the supply between the batteries and the controller. i.e. a bad breaker or fuse, a loose or corroded screw connection, a poorly made or corroded crimp connection, a damaged section of wire, etc.

HINT

A good place to look first is the negative (ground) connection, especially on a European-built boat. These tend to be multiple, common connections that are added to over time.[/quote]

End of Penguin's one-flash advice.

Richard Kollman (another refrigeration pro) adds this about the one flash; as above it is a concern about a voltmeter being used:

• One LED flash and a 4 second pause indicates a boat wiring electrical resistance problem or low batteries. Because of modules sensitive to milliseconds of a voltage spike they cannot be detected by a voltmeter. Solution is to bypass boat’s wiring till problem is located point of electrical resistance.

So that's another way to check it if you have extra cabling: Just hook it up directly with new wire, even if it just runs across the furniture for the test

I have a couple of other documents from other refrigeration sources, but they say basically the same thing. One flash is pretty straightforward.

I'm no expert, but I also can't tell where you are on the scale of knowledge. So if anything about checking it out sounds confusing, say something and maybe I (or someone else here) can explain it in more detail.