BC4Lyphe

Member

Hi I recently bought a 41YF and am slowly updating different systems. Ive gone thru the electrical and it's in good shape for the time being. This summer I'll do a small/simple upgrade to it.

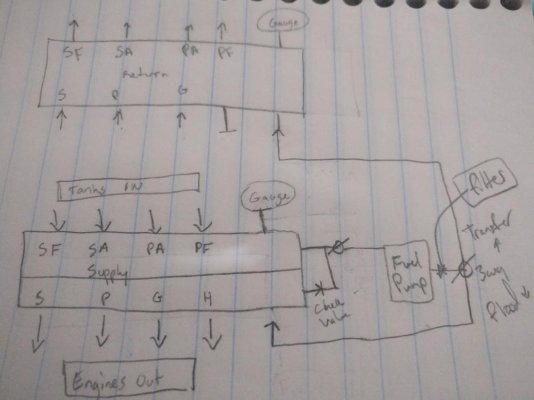

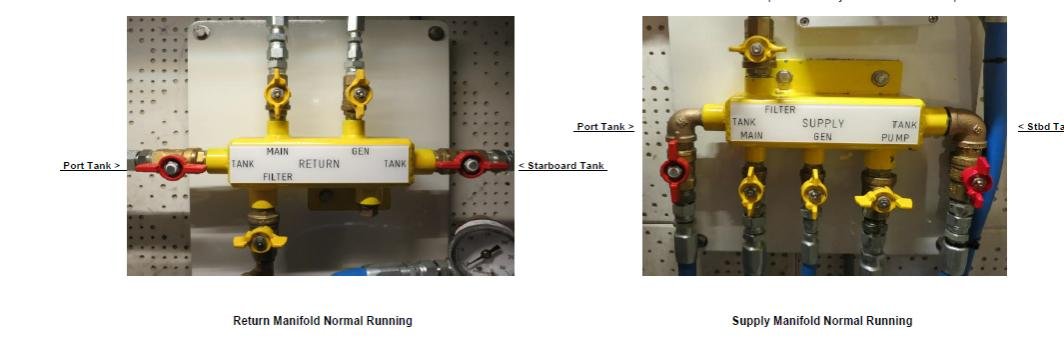

I've got my eye on the fuel system next. I'll have to get photos of the boat but I doubt the valving on there is original. Anyone else with Uniflite fuel photos? Its got four 100 gallon tanks, twin VP 60Bs, a genny, a hydronic heater, two 12 volt Holley fuel pumps. I'm designing a manifold system and was wondering what everyone else was using and how theyve designed it.

I've got my eye on the fuel system next. I'll have to get photos of the boat but I doubt the valving on there is original. Anyone else with Uniflite fuel photos? Its got four 100 gallon tanks, twin VP 60Bs, a genny, a hydronic heater, two 12 volt Holley fuel pumps. I'm designing a manifold system and was wondering what everyone else was using and how theyve designed it.