ca distress

Newbie

- Joined

- May 11, 2016

- Messages

- 2

- Location

- Long Island

- Vessel Name

- Bon Vivant

- Vessel Make

- Nauset 42 - Bruno Stillman

Although I hope one of my twin Cummins next shuts down, it certainly could happen based on a plethora of unexpected mechanical reasons.

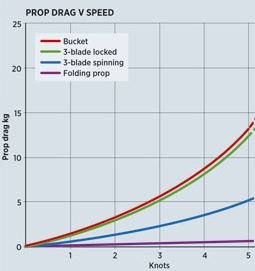

If one engine breaks down forcing you to run on a single, my understanding is that it’s best to lock up the shaft to keep from free spinning. A locked shaft will create less drag (which is counter intuitive but true), and it will also reduce risk of overheating your transmission since that stalled engine cannot oil cool it.

My question is for those who needed to lock up one shaft then running the other engine to reach a destination.

In a pinch, how did you do it? Would a large plumber wrench work, or large vise grips ?

What tips do you have to for the cruiser who needs to lock down down a shaft from free spinning until he gets to port?

If one engine breaks down forcing you to run on a single, my understanding is that it’s best to lock up the shaft to keep from free spinning. A locked shaft will create less drag (which is counter intuitive but true), and it will also reduce risk of overheating your transmission since that stalled engine cannot oil cool it.

My question is for those who needed to lock up one shaft then running the other engine to reach a destination.

In a pinch, how did you do it? Would a large plumber wrench work, or large vise grips ?

What tips do you have to for the cruiser who needs to lock down down a shaft from free spinning until he gets to port?