angus99

Guru

Rod Collins’ articles describe the differing thread pitches typically between the older through-hulls and seacocks, which I found to be true on our DeFever. The SV seacocks and through-hull fittings were basically attached to each other by a couple of mismatched threads and some mastic—no through-bolting. I never put it to the test, but I doubt those connections would survive the 500-lb requirement. Add to that “backing plates” made of thin plywood, a couple of which had the consistency of wet pulp, and replacing all of the seacocks with modern Groco equipment was a no-brainer for me.

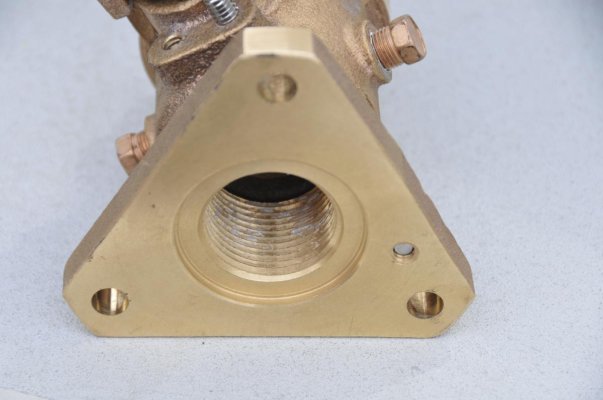

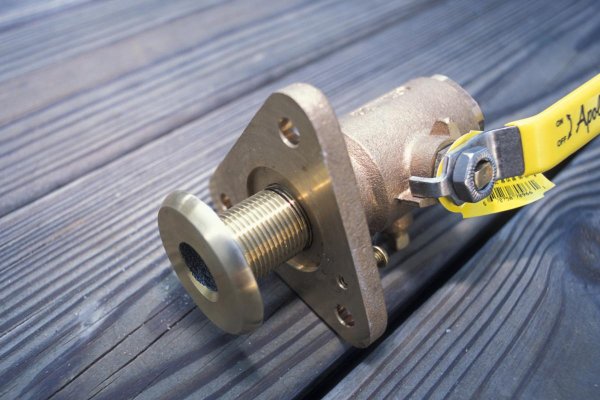

The SVs were very strongly built and several of mine were probably still serviceable. But replacing them with modern ball valves (with replaceable parts), robust flanged adapters (with matched threads that bite deep), and thick composite backing plates (epoxied to the sea chest and hull) was one of the first things we did when we bought our boat. Big bucks but no regrets.

The SVs were very strongly built and several of mine were probably still serviceable. But replacing them with modern ball valves (with replaceable parts), robust flanged adapters (with matched threads that bite deep), and thick composite backing plates (epoxied to the sea chest and hull) was one of the first things we did when we bought our boat. Big bucks but no regrets.