Adventure Time

Member

- Joined

- Aug 29, 2018

- Messages

- 9

- Location

- United States

- Vessel Name

- Adventure Time

- Vessel Make

- Offshore 64

Hi all,

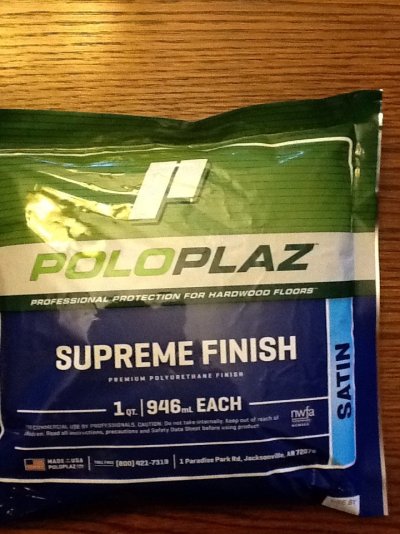

I've been a long time lurker and learn something new here almost every day. I finally have a question worthy of the group, so here we go. My wife and I own an Offshore 64 trawler that we really love. But the wood floors in the salon and galley have taken a bit of abuse from dogs, kids, and fun over the past few years, and we'd like to get them refinished soon. They are solid cherry floors, almost identical to what we had in our last house. I've had two different companies provide quotes, but they were both 4 to 5 times the cost per square foot that we'd expect in a house. I realize the boat has tight corners and less square footage, but this seems really high. Does anybody have a good company they can recommend in the Fort Lauderdale area, or any other ideas about a less exorbitant solution? Thanks in advance!

Malcolm

Adventure Time

I've been a long time lurker and learn something new here almost every day. I finally have a question worthy of the group, so here we go. My wife and I own an Offshore 64 trawler that we really love. But the wood floors in the salon and galley have taken a bit of abuse from dogs, kids, and fun over the past few years, and we'd like to get them refinished soon. They are solid cherry floors, almost identical to what we had in our last house. I've had two different companies provide quotes, but they were both 4 to 5 times the cost per square foot that we'd expect in a house. I realize the boat has tight corners and less square footage, but this seems really high. Does anybody have a good company they can recommend in the Fort Lauderdale area, or any other ideas about a less exorbitant solution? Thanks in advance!

Malcolm

Adventure Time