Cold Shot

Veteran Member

- Joined

- Feb 27, 2019

- Messages

- 26

- Location

- U.S.A

- Vessel Name

- Cold Shot

- Vessel Make

- 1997 38' Luhrs Tournament Open

Good morning fellas,

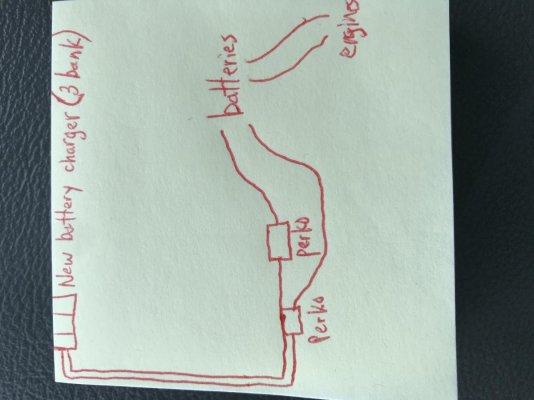

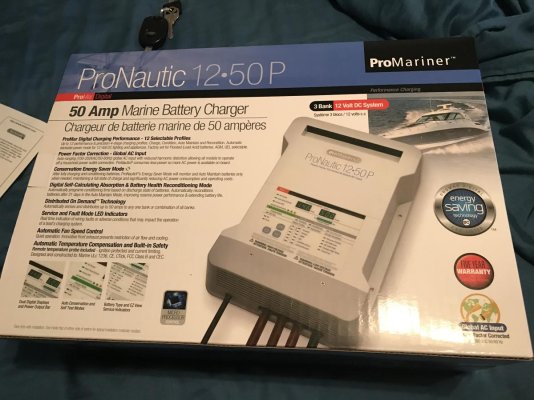

I’m ordering parts on Amazon now to rewire from new battery charger to two 8D batteries. It’s a 12v system with two Diesel engines. The main wire from charger to batteries is 4 AWG. I want to add a bussbar near the batteries and remove the wing nut terminals.. The system runs through two large Perko switches which I’ll keep. The new batteries aren’t charging well. The drawing below is a rough sketch of how I think it’s set up. I need suggestions on what to buy. Thanks for any suggestions in advance. I’m doing the work this weekend.

So far I have

15’ of new 4 AWG wire (red and black)

Lugs

Heat shrink

I’m ordering parts on Amazon now to rewire from new battery charger to two 8D batteries. It’s a 12v system with two Diesel engines. The main wire from charger to batteries is 4 AWG. I want to add a bussbar near the batteries and remove the wing nut terminals.. The system runs through two large Perko switches which I’ll keep. The new batteries aren’t charging well. The drawing below is a rough sketch of how I think it’s set up. I need suggestions on what to buy. Thanks for any suggestions in advance. I’m doing the work this weekend.

So far I have

15’ of new 4 AWG wire (red and black)

Lugs

Heat shrink

Attachments

-

55AA13CB-BACC-4564-9C99-3B60D7E1BAC0.jpg142.7 KB · Views: 85

55AA13CB-BACC-4564-9C99-3B60D7E1BAC0.jpg142.7 KB · Views: 85 -

DBCBE23B-018B-4416-8182-F5FBD804218C.jpg92.3 KB · Views: 92

DBCBE23B-018B-4416-8182-F5FBD804218C.jpg92.3 KB · Views: 92 -

3472C4A3-3870-4F93-B026-C6E9DB6AF17F.jpg138.8 KB · Views: 81

3472C4A3-3870-4F93-B026-C6E9DB6AF17F.jpg138.8 KB · Views: 81 -

07BE6CEB-3957-466F-B576-431418B233BE.jpg165.9 KB · Views: 87

07BE6CEB-3957-466F-B576-431418B233BE.jpg165.9 KB · Views: 87 -

3994E0F1-8927-44FD-809F-4D58BABF2C6B.jpg95.6 KB · Views: 100

3994E0F1-8927-44FD-809F-4D58BABF2C6B.jpg95.6 KB · Views: 100