Great information well written.

I've read different opinions. Should both nuts be torqued the same and are there accepted bronze nut to stainless shaft torque value tables based on shaft diameter?

Thanks for your contribution to this forum.

While it would be the right way to install any critical fastener, I can't recall the last time I saw a yard use a torque wrench on a prop nut, so it may be a non issue. Bronze nuts (these are typically manganese bronze, so really brass) are self-lubricating (they won't gall). You can look up the torque value of a given diameter, and I'd use bronze/brass as the material, but again, in most cases the yard is using a large wrench (hopefully smooth jaw), and a big guy to heave on it.

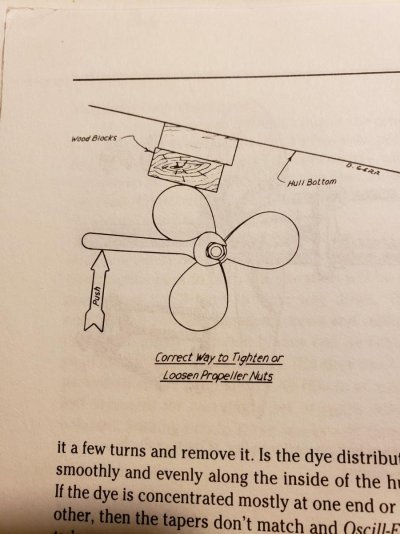

Following the installation procedures is key, no pun intended, make sure there is no key binding, perform the lapping procedure, lightly oil the shaft taper and key, block the prop to the hull, install the large nut first, then remove it, then install the half nut, and then large nut. Get all that right and you are likely to never have a prop loss issue.

Now, if you are intent on torquing the nuts, here's the drill...

"Firstly, on a propeller taper, the propeller hub has to be pressed onto the taper using more force than the thrust generated by the propeller itself.

This ensures that it will not move further up the taper under normal thrust loads thereby loosening the propeller nut.

(using 3” diameter shaft as illustration)

In tons, the clamping force required is:

Nominal diameter of shaft x condition factor.

(Factor 2.875 is dry taper ; 2.6 is for oiled taper)

3 x 2.875 = 8.625 TonsF.

Convert to Lbs.:

2.875 x 2240 Lbs. = 19,320 LbsF.

Torque required on nut to deliver clamping force of 19,320 Lbs:

(Nom Diameter of thread (2.25) x Factor x LbsF) / 12).

(Factor is 0.2 for dry thread ; 0.15 for oiled thread)

2.25 x 0.2 x 19,320 = 8,694 Inch/Lbs.

Divided by 12 = 724 Ft/Lbs.

The above can be adjusted by experiment as some boats do not generate as much thrust as is possible on some high speed boats, the variable is the factor."

Next, find a torque wrench that can measure 724 Ft/lbs...