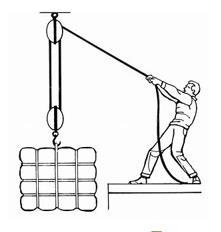

You are all confusing the effort required to lift a weight with the breaking strength of the line, in this case we are assuming 5000# breaking strength. Forgetting for a moment that lines are rated lower than their actual failure point, you could lift 5000#. The purpose of the ropes and pulleys (on a boat, that is a "purchase") is to lower the amount of work that is required to be expended to lift that weight, by a factor of the number of pulleys and the number of "lines," making it possible for one person to lift a much larger load than they could directly. The earlier poster was correct, the breaking strength of the rope must be less than the load or you will drop it.

The purpose of a tackle is also to be able to lift something heavier than the line's load rating or breaking strength. A 5000 lb strength line on a 4:1 tackle will fail at 20,000 lbs load on the tackle, not 5000, if the blocks are rated for 20,0000. If the safe load for the 5000 lb line is 2000 lbs, then a 4:1 tackle using it will lift 8000 lbs safely (provided the blocks are up to it) - much higher than the 5000 lb breaking load of the line.