macsail

Member

1984 Marine Trader 50,

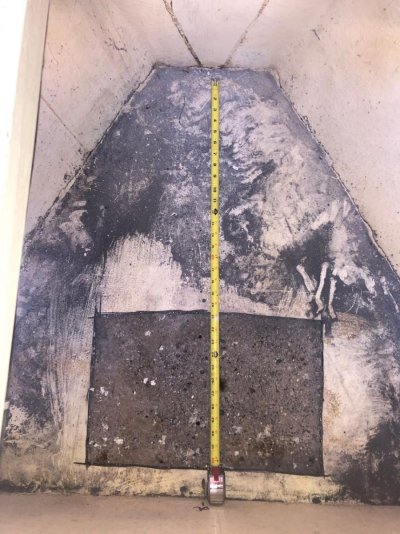

We were about to install a bow thruster, and found a large poured lead/concrete fill in the forepeak below a fiberglassed cover. Drilled down at least 9 inches and all solid. I assume that the lead/concrete mixture was poured for weight and balance during construction. It covers a large area, extending back to the fwd water tank and appears flush with the hull.

The problem is that the yard in New Orleans is stumped on how to do the tunnel bore. Florida Bow Thrusters won't touch it either.

* Is this common for MT 50's or other trawlers to have this fill in the bow?

* Any ideas on how to do the bore?

I'm starting to think that I'll have a new bow thruster system for sale (past return date by 1 week).

We were about to install a bow thruster, and found a large poured lead/concrete fill in the forepeak below a fiberglassed cover. Drilled down at least 9 inches and all solid. I assume that the lead/concrete mixture was poured for weight and balance during construction. It covers a large area, extending back to the fwd water tank and appears flush with the hull.

The problem is that the yard in New Orleans is stumped on how to do the tunnel bore. Florida Bow Thrusters won't touch it either.

* Is this common for MT 50's or other trawlers to have this fill in the bow?

* Any ideas on how to do the bore?

I'm starting to think that I'll have a new bow thruster system for sale (past return date by 1 week).