You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hull Laboratory Results- Ranger Tug

- Thread starter bucketlist1

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

- Status

- Not open for further replies.

Given that the hull is quite thin, I would have expected that the designers would have opted for vinyl ester. This excerpt from a Boat magazine article explains it rather well. Better impact strength plus osmosis protection.

"Also in this category are the vinylester resins. They are more expensive but do not have the ester linkage. Instead, they have an ether linkage, a more moisture-stable connector in the molecule. These resins have great chemical and moisture resistance. They are also much tougher and more flexible than the others. This means that design stress levels can be higher in the composites. This equates to a lighter, more durable boat that can take a beating and keep on ticking without cracking or breaking. Vinylesters are what gave us a revolution back in the early ’80s, when builders could begin to produce hulls that would not blister. Blistering, as you recall, is an indirect result of the ester linkages breaking in the presence of water. Therefore, vinylester resins are the resin of choice for the seeker of a trouble-free experience. You should make sure that your boat is produced with them if the boatbuilder works with polyester resins".

"Also in this category are the vinylester resins. They are more expensive but do not have the ester linkage. Instead, they have an ether linkage, a more moisture-stable connector in the molecule. These resins have great chemical and moisture resistance. They are also much tougher and more flexible than the others. This means that design stress levels can be higher in the composites. This equates to a lighter, more durable boat that can take a beating and keep on ticking without cracking or breaking. Vinylesters are what gave us a revolution back in the early ’80s, when builders could begin to produce hulls that would not blister. Blistering, as you recall, is an indirect result of the ester linkages breaking in the presence of water. Therefore, vinylester resins are the resin of choice for the seeker of a trouble-free experience. You should make sure that your boat is produced with them if the boatbuilder works with polyester resins".

Hull thickness and voids aside, what got my attention in the report is the use of polyester resin versus vinyl ester.

Calling a 50 micron gap between 40 micron fibers a void is stretching the word void.

I suspect all production boats use polyester resin so why would that be an issue? There is an infinite variety of mix ratios for both resins so drawing any conclusions from type of resin is meaningless. Layup schedule would be more relevant in determining strength and flexibility but that is proprietary and the lab report is vague. (And I don't think a 2013 article from a boating magazine is the go to source for fiberglass boat design)

The lab report simply lists some chemical and physical features but is silent regarding what caused the damage. The boat did not spontaneously crack. Any conclusion about cause is just guessing.

Last edited:

FWT

Guru

- Joined

- Dec 10, 2020

- Messages

- 1,520

- Vessel Name

- Resilient

- Vessel Make

- Helmsman Trawlers 38E

The boat did not spontaneously crack. Any conclusion about cause is just guessing.

63 posts, and that's still the most important point.

bfloyd4445

Guru

63 posts, and that's still the most important point.

And we are still waiting for Bucket list 1 who started this thread to answer our questions regaurding the cause.

SeaDogAK

Senior Member

- Joined

- Aug 9, 2021

- Messages

- 305

- Vessel Name

- Sea Dog

- Vessel Make

- 1991 DeFever 49 RPH

Complaining that your lightweight trailerable boat has a thin hull is like buying a Mini Cooper and then complaining that it doesn’t have enough head room.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,297

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Actually Mini Coopers have pretty good headroom, their problem is that you have to get down to the road to get in and out of them. But I get your point.

I suspect all production boats use polyester resin so why would that be an issue? There is an infinite variety of mix ratios for both resins so drawing any conclusions from type of resin is meaningless.

I don't understand the second part of this comment. It sounds like you are saying that, type of resin aside, you can mix it differently to come out with different characteristics.

I don't believe this to be true. With polyester (and I think vinylester also) you mix it according to the temperature of the work surface. Higher temp means smaller amount of catalyst; lower temps equal more catalyst (for a given same amount of resin).

But I don't think any of those ratios produce a different end product. It's just that you want to use the correct ratio for the temperature. But you can't "upgrade the strength by mixing it differently as far as I know.

Same with epoxy. In this case the mix ratio is set and doesn't vary; but you choose a hardener based on ambient/work surface temperatures. This controls the cure time. For WEST there are specification charts. If I remember correctly there is a tiny different in strength for slow vs. fast hardener, but it's a tiny percentage. So it's not like you "mix it differently" in order to change that.

What you said afterward about layup schedule is true. Also depending on how you lay it up, you can get a different ratio of resin to cloth, which can affect strength to weight ratio.

Anyway, if there is something new I don't know about in regards to mix ratios, I'm interested. But in my experience it's not like you can change a mix ratio and get a stronger polyester or vinylester. You just get one that cures better or worse for a given temperature.

Complaining that your lightweight trailerable boat has a thin hull is like buying a Mini Cooper and then complaining that it doesn’t have enough head room.

Plus a hull being thin does not mean it's weak. The whole rant is useless as all we have is someone trying to prove something he can't prove. So stay tuned for more holes and less boating and more suppositions and accusations, none supported by facts.

This excerpt from a Boat magazine article explains it rather well.

"Also in this category are the vinylester resins. They are more expensive ....".

And hence very rarely used in a value class boat except sometimes as a barrier coat.

I don't believe this to be true. With polyester (and I think vinylester also) you mix it according to the temperature of the work surface. Higher temp means smaller amount of catalyst; lower temps equal more catalyst (for a given same amount of resin).

Correct. I left out the detail. I was thinking more about adjusting cure times to to match temp and humidity. It is also possible large manufacturers will adjust viscosity to match their application equipment and there may be more additives but in general I think you added the detail I skipped.

hollywood8118

Guru

- Joined

- Nov 16, 2009

- Messages

- 2,381

- Location

- USA

- Vessel Name

- " OTTER "

- Vessel Make

- Ocean Alexander Europa 40

Complaining that your lightweight trailerable boat has a thin hull is like buying a Mini Cooper and then complaining that it doesn’t have enough head room.

At 6'2" our Mini Cooper S JSW has plenty of headroom.

If I had bought it and expected it to ride like an Escalade then complained about it, that would be a problem.

Hollywood

BINGO!

A recent post showed a thick cored hull section. The same problem exists with improper ground handling...pad lift hydraulic trailers in particular. I've alerted ABYC regarding this looming menace and suggested that they require manufacturers of cored hulls to issue specialized ground handling instructions. They're negligent if they haven't. If you have a boat with a cored hull and it's been on a pad lift hydraulic trailer, odds are high that the core material has local crush damage...you just don't know it yet.

Thank you bucketlist1.

You are painting with an extremely broad brush, a "cored hull" can range from fragile to bullet proof. I work with many fully cored hulls, they are lifted, blocked, moved on hydraulic trailers and very few suffer damage or delamination. It all depends on the scantlings and quality of construction, as well as the lifting and blocking procedures. Most manufacturers provide gravign instructions upon request if not in the owner's manual.

ABYC's mandate is not to prescribe for boat builders how to build boats, it's to make boats safer. If multiple boats are sinking because of this phenomenon, then they will consider writing a standard, but keep in mind this organization hasn't seen the need for a hull scantling standard yet, and it's over 50 years old. To call them negligent belies your misunderstanding of the organization's charter.

I assure you I understand ABYC's "charter". It's similar to that of alphabet groups that linger around the FAA aircraft certification regulatory community where I spent 30 years. Unfortunately (or fortunately depending on your point of view) the Coast Guard is virtually hands off in the recreational boating manufacturing arena. In the case of the FAA, advisory material provides one way, but not the only way to comply with a safety standard. It amounts to design criteria. ABYC gets very close to that in some of their material.

As I alluded to earlier, for 16 years I've spent a couple of weeks every Spring and Fall in a huge heated storage building prepping my boat for launch and putting it to bed for the winter. I didn't just observe the continuous boat movements taking place around me...I helped block the hull, insert jack stands and drove my own boat into and out of the lift basin. I did so to protect my investment. If you haven't seen activities that can/do cause damage to owner's boats, you haven't looked closely enough or been around a Great Lakes yard in the Spring or Fall when there's a frenzy of launch or recovery activity.

Alarmed at what I was seeing and experiencing, I contacted ABYC (virtually as a last resort) several years ago. My timing was perfect as ABYC were just initiating development of a new section for ground handling. Their manager of "standards" development heard my story, and invited me to submit material for their upcoming working group in New Orleans. Life got in the way, and I missed the submittal deadline for working group material. It's in their files for the next go around. By the way, I was referring to manufacturer's being negligent for not providing ground handling instructions, not ABYC.

The primary focus of my material is on ground handling equipment interface/design with various hull designs, and ground crew training and awareness. It urges ground equipment operators to seek information from hull manufacturers, and advises trailer designers to do the same before they launch a product. If hull manufacturers are issuing readily available, detailed information beyond sling lift markings, I haven't seen it and neither have the ground crews I've spoken with. Ground crews lift, load, move, and block as fast as they possibly can with little or no regard or knowledge of hull design or materials. That's the real world.

In my estimation this particular fracture resulted from a very localized load against the hull probably during ground handling or less likely a grounding. (If it can be determined that it resulted from a debris strike on the water, then there is a big safety issue looming). In fact even an undetected crack from a ground handling incident could be construed to be a safety issue if a boat sinks after launch. Speculation? No. Engineering judgement and experience....much of it with certification of aircraft composite structure.

I noted that you say that "very few" cored hulls have been damaged during ground handling. One is too many. By the way, one is parked next to us at the moment. Core compression is difficult to see. Same for minute skin cracks that go with it. Issues will show up down the road. I want be clear that I don't view cored hulls as inherently unsafe. They simply require special ground handling...and more related information/cautions from the manufacturers. They'd obviously not give any indication that their cored products require special care.

Finally, I believe Ranger should engage the OP and get to the heart of this matter. If it takes subjecting a test hull to full scale destructive testing to prove their design is up to the rigors of real world operations, then do it. It's a lingering PR problem if they don't. (I'd be surprised if they didn't do detailed impact/load testing during development).

As I alluded to earlier, for 16 years I've spent a couple of weeks every Spring and Fall in a huge heated storage building prepping my boat for launch and putting it to bed for the winter. I didn't just observe the continuous boat movements taking place around me...I helped block the hull, insert jack stands and drove my own boat into and out of the lift basin. I did so to protect my investment. If you haven't seen activities that can/do cause damage to owner's boats, you haven't looked closely enough or been around a Great Lakes yard in the Spring or Fall when there's a frenzy of launch or recovery activity.

Alarmed at what I was seeing and experiencing, I contacted ABYC (virtually as a last resort) several years ago. My timing was perfect as ABYC were just initiating development of a new section for ground handling. Their manager of "standards" development heard my story, and invited me to submit material for their upcoming working group in New Orleans. Life got in the way, and I missed the submittal deadline for working group material. It's in their files for the next go around. By the way, I was referring to manufacturer's being negligent for not providing ground handling instructions, not ABYC.

The primary focus of my material is on ground handling equipment interface/design with various hull designs, and ground crew training and awareness. It urges ground equipment operators to seek information from hull manufacturers, and advises trailer designers to do the same before they launch a product. If hull manufacturers are issuing readily available, detailed information beyond sling lift markings, I haven't seen it and neither have the ground crews I've spoken with. Ground crews lift, load, move, and block as fast as they possibly can with little or no regard or knowledge of hull design or materials. That's the real world.

In my estimation this particular fracture resulted from a very localized load against the hull probably during ground handling or less likely a grounding. (If it can be determined that it resulted from a debris strike on the water, then there is a big safety issue looming). In fact even an undetected crack from a ground handling incident could be construed to be a safety issue if a boat sinks after launch. Speculation? No. Engineering judgement and experience....much of it with certification of aircraft composite structure.

I noted that you say that "very few" cored hulls have been damaged during ground handling. One is too many. By the way, one is parked next to us at the moment. Core compression is difficult to see. Same for minute skin cracks that go with it. Issues will show up down the road. I want be clear that I don't view cored hulls as inherently unsafe. They simply require special ground handling...and more related information/cautions from the manufacturers. They'd obviously not give any indication that their cored products require special care.

Finally, I believe Ranger should engage the OP and get to the heart of this matter. If it takes subjecting a test hull to full scale destructive testing to prove their design is up to the rigors of real world operations, then do it. It's a lingering PR problem if they don't. (I'd be surprised if they didn't do detailed impact/load testing during development).

Last edited:

Finally, I believe Ranger should engage the OP and get to the heart of this matter. If it takes subjecting a test hull to full scale destructive testing to prove their design is up to the rigors of real world operations, then do it. It's a PR problem if they don't. (I'd be surprised if they didn't do detailed impact testing during development).

This is the 4th thread on this subject by the OP, he has a website devoted to the topic and had posted on the Tugnuts forum until he was removed. He has made so many repeated and unsubstantiated allegations I would suspect he not only burned that bridge but made charcoal briquettes from the ashes and burned those too.

I haven't seen specific allegations. From what I've seen he's providing test data.

I personally think he's looking in the wrong places, but that's his choice.

Actually, he's provided nothing. He doesn't have any idea when or how it happened. He didn't survey. He didn't even check it. Could be so many different things.

He doesn't even know who to go after. Mover? Dealer? Previous Owner? Builder?

So he just rants endlessly against what I guess he considers the biggest target. We get iPhones brought in every day that failed for no reason. Only when we pour the water out do some of the customers admit dropping it into the toilet.

In my estimation this particular fracture resulted from a very localized load against the hull probably during ground handling or less likely a grounding.

Finally, I believe Ranger should engage the OP and get to the heart of this matter. If it takes subjecting a test hull to full scale destructive testing to prove their design is up to the rigors of real world operations, then do it. It's a lingering PR problem if they don't. (I'd be surprised if they didn't do detailed impact/load testing during development).

You believe the damage resulted from a very localized load against the hull, but you also believe Ranger should spend hundreds of thousands in destructive testing to prove their boats will survive any manner of negligent operation and handling. Should they make their hull 3" thick just in case a yard monkey blocks it incorrectly?

I think everyone on the thread is in agreement that the damage appears to be from a drop, and the OP assumed the risk by foregoing a survey. The OP states on his anti-Ranger website that several haulers were involved transporting the boat at various times. The OP also briefly mentions the original owners launch/retrieval contraption.

All the destructive testing n the world is not going to answer the question of who did what when.

I don't see "rants" from the OP. He's persistent and calm from what I've read. The rants (mostly personal attacks against him) come from the peanut gallery.

Perhaps he's not "going after" anyone. Perhaps he's going after the truth, and the only way to zero in on it is likely by backing into it with lab testing. As I said, larger scale destructive testing is likely to produce more definitive results, but that's big bucks.

Unlike aircraft where manufacturers are required to submit detailed structural test data for government approval...the recreational boating manufacturing community gets away with testing their products via their customers. That leaves customers with little leverage if the manufacturer chooses not to assist.

Perhaps he's not "going after" anyone. Perhaps he's going after the truth, and the only way to zero in on it is likely by backing into it with lab testing. As I said, larger scale destructive testing is likely to produce more definitive results, but that's big bucks.

Unlike aircraft where manufacturers are required to submit detailed structural test data for government approval...the recreational boating manufacturing community gets away with testing their products via their customers. That leaves customers with little leverage if the manufacturer chooses not to assist.

All the destructive testing n the world is not going to answer the question of who did what when.

But he has proven you can drill holes in the boat.

Now the big question, will he ever repair it and actually use it? At this point his only option is using it because he certainly has destroyed any resale value? And will he or anyone ever be able to insure it now?

Last time I saw anything like this, I was a child. The state of NC was trying to use eminent domain to buy property for a road. The owner refused to sell, so it went to court. The state had tried to buy his entire property, but apparently through eminent domain could only buy the part they needed. Now as that went to the middle of his house, that created a problem. I don't know who or how, but for years half the house stood where someone had cut a line right through it. It was open on that side with a huge sign, "Look what the state of NC did to me." Now, factually I believe they paid for the entire house in damages and the neighbor who did sell and then move his house said the guy had been offered far above market. But, I guess he had a point to make and did so. Debate would be what point did he really make.

You believe the damage resulted from a very localized load against the hull, but you also believe Ranger should spend hundreds of thousands in destructive testing to prove their boats will survive any manner of negligent operation and handling. Should they make their hull 3" thick just in case a yard monkey blocks it incorrectly?

I think everyone on the thread is in agreement that the damage appears to be from a drop, and the OP assumed the risk by foregoing a survey. The OP states on his anti-Ranger website that several haulers were involved transporting the boat at various times. The OP also briefly mentions the original owners launch/retrieval contraption.

All the destructive testing n the world is not going to answer the question of who did what when.

I believe Ranger should have done destructive testing during their development stage in order to establish whether special precautions should have been issued for ground handling. If it has areas in the hull that are vulnerable, that information should be clearly stated and readily available to owners and ground crews. It's a thin hull and very likely has vulnerabilities that would not be expected by typical uninformed ground handling crews. Of course manufacturers of light weight boats wouldn't want to admit that...and I doubt Ranger has this data.

If Ranger or anyone else want to build a 1/4" thick hull or a cored hull boat by all means have at it...but document the engineering testing that supports that decision. If they say the boat hull is bullet proof, I'd say show me your test results. BTW, one of the things they could have done to mitigate the ground handling fragility issue is utilizing more robust resins. They chose not to. There are (or at least should be) consequences for those decisions. In the aircraft world, their type certificate could have been on the line.

I don't believe for a second that the damage was caused by a drop.

It would be interesting to establish who did what when. But that's a liability question. The issue is what physical event (within the realm of the two or three days in question) could have created the damage. Process of elimination. Ranger should have related test data in their files....but again, I have a hunch they don't. Hence their reluctance to engage. I was suggesting that OP could do testing to make his points, not Ranger. The tram retrieval device, which I mentioned months ago, should be investigated. If a drop test duplicated the failure...end of story. But better for Ranger to help get to the bottom of this.

Last edited:

RUFUS: 9/12/21, 12:25PM: "In my estimation this particular fracture resulted from a very localized load against the hull probably during ground handling or less likely a grounding."

RUFUS: 9/12/2021, 2:40PM; "I don't believe for a second that the damage was caused by a drop."

Ergo you have decided with zero evidence that it was rogue hydraulic trailer pad or original owner hit a rock. You have eliminated the original owners retrieval railway contraption and have eliminated any accidental drops. I'm sure you'll make a great expert witness.

I have no doubt that Ranger has extensive design test data in their files and I'll bet they test each batch of resin for quality conformance. All available in Discovery phase once OP files civil suit but apparently he has yet to find a lawyer who will file the case.

I can't imagine Ranger or any other manufacturer would release proprietary design and test data without a court order and any court would grant a request to seal the data. I agree with your suggestion that OP should proceed with destructive testing to make his point. But why would you suggest he do a drop test "If a drop test duplicated the failure...end of story" when you earlier stated the damage could not have resulted from a drop?

I'm waiting for the OP's destructive testing videos. Potential viral material!

RUFUS: 9/12/2021, 2:40PM; "I don't believe for a second that the damage was caused by a drop."

Ergo you have decided with zero evidence that it was rogue hydraulic trailer pad or original owner hit a rock. You have eliminated the original owners retrieval railway contraption and have eliminated any accidental drops. I'm sure you'll make a great expert witness.

I have no doubt that Ranger has extensive design test data in their files and I'll bet they test each batch of resin for quality conformance. All available in Discovery phase once OP files civil suit but apparently he has yet to find a lawyer who will file the case.

I can't imagine Ranger or any other manufacturer would release proprietary design and test data without a court order and any court would grant a request to seal the data. I agree with your suggestion that OP should proceed with destructive testing to make his point. But why would you suggest he do a drop test "If a drop test duplicated the failure...end of story" when you earlier stated the damage could not have resulted from a drop?

I'm waiting for the OP's destructive testing videos. Potential viral material!

Last edited:

No, I included the tram retrieval system for investigation and pointed to it months ago if you care to look at old posts. Could have been a soft grounding or maybe a submerged log. Something that didn't leave obvious tell tails on the hull. My point (not well stated in that earlier post) is that if Ranger has developmental test data that could show conclusively that it was dropped, they'd have presented it long ago. Why sit on it and take the negative PR. I'm sure they have drawers full of coupon data...what about smacking the hull with foreign objects. (I was actually a pretty decent expert witness in the aviation community....no need to throw around insults).

Coupon tests are a red herring and a rabbit hole the the OP unfortunately elected to pursue. The hull was whacked or deflected in a relatively subtle manner...not from a drop that would have left obvious visible evidence on the surface.

There will be other hull damage incidents and the word will get out. I'm afraid the small boat manufacturing community might be headed for increased, standardized technical oversite from the Coast Guard. It's probably overdue. Ranger should get out in front of this...if they have the ability to do so. One has to wonder.

Coupon tests are a red herring and a rabbit hole the the OP unfortunately elected to pursue. The hull was whacked or deflected in a relatively subtle manner...not from a drop that would have left obvious visible evidence on the surface.

There will be other hull damage incidents and the word will get out. I'm afraid the small boat manufacturing community might be headed for increased, standardized technical oversite from the Coast Guard. It's probably overdue. Ranger should get out in front of this...if they have the ability to do so. One has to wonder.

Last edited:

bucketlist1

Veteran Member

Thanks everyone , I am caught up on all the posts . I am not going to keep repeating my answers . The web site , I think fairly tells the story , the videos are real ( some question if I sent the real samples ! ) . Bottom line is 1- damage happen before I took possession 2- Damage was from blocking previously ( could have been at plant , freight to dealer or at dealer ) 3- blocking was not done behind the proper area . 4- most agree , 6.3 mm hull thickness at hull is too thin 5- you can get away with ''thin '' if your using epoxy resin , special composites like carbon fiber, resin infused , vaccuum bagged etc . Rangers to my knowledge are hand lay up , regular resin and matting/roving . The tests i had done , ended up being '' average '' for production boat building ( which I think is nothing to be proud of , for an expensive boat ) . Bottom line is 6.3 mm thickness at the keel gives you no room for a slight error in blocking or even a sand bar . Kind of like you drive through a pot hole with your car and it bends the unibody or frame .

BandB will be happy to know this will my last post ( about this issue ) and I do appreciate the views of Rufus and some of the others . If you read my website , I am not the only one that had a non accident crack , Jfrano had his Ranger Tug fixed under warranty I believe , because he was original owner . That is why I was kicked off ''tugnuts '' because I asked about his situation-- '' cause and repair procedure '' That post disappeared in less than a hour on Tugnuts .

BandB will be happy to know this will my last post ( about this issue ) and I do appreciate the views of Rufus and some of the others . If you read my website , I am not the only one that had a non accident crack , Jfrano had his Ranger Tug fixed under warranty I believe , because he was original owner . That is why I was kicked off ''tugnuts '' because I asked about his situation-- '' cause and repair procedure '' That post disappeared in less than a hour on Tugnuts .

No, I included the tram retrieval system for investigation and pointed to it months ago if you care to look at old posts. Could have been a soft grounding or maybe a submerged log. Something that didn't leave obvious tell tails on the hull. My point (not well stated in that earlier post) is that if Ranger has developmental test data that could show conclusively that it was dropped, they'd have presented it long ago. Why sit on it and take the negative PR. I'm sure they have drawers full of coupon data...what about smacking the hull with foreign objects. (I was actually a pretty decent expert witness in the aviation community....no need to throw around insults).

Coupon tests are a red herring and a rabbit hole the the OP unfortunately elected to pursue. The hull was whacked or deflected in a relatively subtle manner...not from a drop that would have left obvious visible evidence on the surface.

There will be other hull damage incidents and the word will get out. I'm afraid the small boat manufacturing community might be headed for increased, standardized technical oversite from the Coast Guard. It's probably overdue. Ranger should get out in front of this...if they have the ability to do so. One has to wonder.

Ranger shouldn't get out in front. They should stay where they are, 100% out of this entire situation. They were not a party to the sale of the boat to the individual involved. The boat was clearly damaged as the result of some incident either while under the previous owner's control or the current owner or on the yard or while operated by the sales person or while being loaded or while being trailered. They have zero knowledge of the event leading to this. They don't have a general hull problem, don't have a rash of issues. No insurer has initiated a complaint against Ranger.

I'll give you the opposite. Bertram had cases of delamination. First case they might have claimed it was abusive conditions, but multiple cases that they had to respond to and take care of. Bertram was forced to step up. The evidence was clear, insurance surveyors confirmed it. This isn't that. This is one owner of a Ranger ranting against the company with zero evidence of anything they did wrong or any responsibility of the company toward him.

Ranger has no reason to get involved in a situation where they are not a party.

Ranger shouldn't get out in front. They should stay where they are, 100% out of this entire situation. They were not a party to the sale of the boat to the individual involved. The boat was clearly damaged as the result of some incident either while under the previous owner's control or the current owner or on the yard or while operated by the sales person or while being loaded or while being trailered. They have zero knowledge of the event leading to this. They don't have a general hull problem, don't have a rash of issues. No insurer has initiated a complaint against Ranger.

I'll give you the opposite. Bertram had cases of delamination. First case they might have claimed it was abusive conditions, but multiple cases that they had to respond to and take care of. Bertram was forced to step up. The evidence was clear, insurance surveyors confirmed it. This isn't that. This is one owner of a Ranger ranting against the company with zero evidence of anything they did wrong or any responsibility of the company toward him.

Ranger has no reason to get involved in a situation where they are not a party.

I just read the OP's latest and apparently last post on the subject. This is at least the second crack event. More to come. Regards.

Benthic2

Guru

He has a lawyer but hasn't sued.

He has insurance but won't issue a claim

He has a boat that he doesn't want to go boating in.

ergo, he is irrational and can not be reasoned with.

He has insurance but won't issue a claim

He has a boat that he doesn't want to go boating in.

ergo, he is irrational and can not be reasoned with.

I assure you I understand ABYC's "charter". It's similar to that of alphabet groups that linger around the FAA aircraft certification regulatory community where I spent 30 years. Unfortunately (or fortunately depending on your point of view) the Coast Guard is virtually hands off in the recreational boating manufacturing arena. In the case of the FAA, advisory material provides one way, but not the only way to comply with a safety standard. It amounts to design criteria. ABYC gets very close to that in some of their material.

As I alluded to earlier, for 16 years I've spent a couple of weeks every Spring and Fall in a huge heated storage building prepping my boat for launch and putting it to bed for the winter. I didn't just observe the continuous boat movements taking place around me...I helped block the hull, insert jack stands and drove my own boat into and out of the lift basin. I did so to protect my investment. If you haven't seen activities that can/do cause damage to owner's boats, you haven't looked closely enough or been around a Great Lakes yard in the Spring or Fall when there's a frenzy of launch or recovery activity.

Alarmed at what I was seeing and experiencing, I contacted ABYC (virtually as a last resort) several years ago. My timing was perfect as ABYC were just initiating development of a new section for ground handling. Their manager of "standards" development heard my story, and invited me to submit material for their upcoming working group in New Orleans. Life got in the way, and I missed the submittal deadline for working group material. It's in their files for the next go around. By the way, I was referring to manufacturer's being negligent for not providing ground handling instructions, not ABYC.

The primary focus of my material is on ground handling equipment interface/design with various hull designs, and ground crew training and awareness. It urges ground equipment operators to seek information from hull manufacturers, and advises trailer designers to do the same before they launch a product. If hull manufacturers are issuing readily available, detailed information beyond sling lift markings, I haven't seen it and neither have the ground crews I've spoken with. Ground crews lift, load, move, and block as fast as they possibly can with little or no regard or knowledge of hull design or materials. That's the real world.

In my estimation this particular fracture resulted from a very localized load against the hull probably during ground handling or less likely a grounding. (If it can be determined that it resulted from a debris strike on the water, then there is a big safety issue looming). In fact even an undetected crack from a ground handling incident could be construed to be a safety issue if a boat sinks after launch. Speculation? No. Engineering judgement and experience....much of it with certification of aircraft composite structure.

I noted that you say that "very few" cored hulls have been damaged during ground handling. One is too many. By the way, one is parked next to us at the moment. Core compression is difficult to see. Same for minute skin cracks that go with it. Issues will show up down the road. I want be clear that I don't view cored hulls as inherently unsafe. They simply require special ground handling...and more related information/cautions from the manufacturers. They'd obviously not give any indication that their cored products require special care.

Finally, I believe Ranger should engage the OP and get to the heart of this matter. If it takes subjecting a test hull to full scale destructive testing to prove their design is up to the rigors of real world operations, then do it. It's a lingering PR problem if they don't. (I'd be surprised if they didn't do detailed impact/load testing during development).

With all due respect to your engineering and aviation background, and I mean that sincerely, the recreational marine industry is not the aviation industry, one is lightly regulated, the other regulated out the proverbial wazoo, with good reason, people die routinely when aviation mishaps occur, not so with failures of cored hulls on recreational craft.

Conservatively speaking I've personally hauled and blocked, or been responsible for hauling and blocking, approximately 2,000 vessels in my career. While your observations from blocking your own vessel and observing other vessels being blocked over a period of a few weeks each hauling and launching season is not without merit, it is hardly a cross section.

Understood on the negligence accusation, it was aimed not ABYC, but boat builders. Again, that's pretty broad, how many of them have you solicited fo gravign plans?

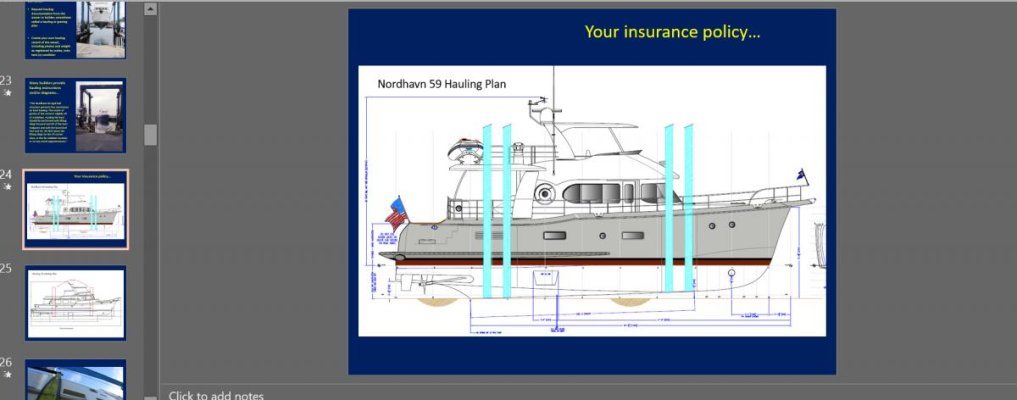

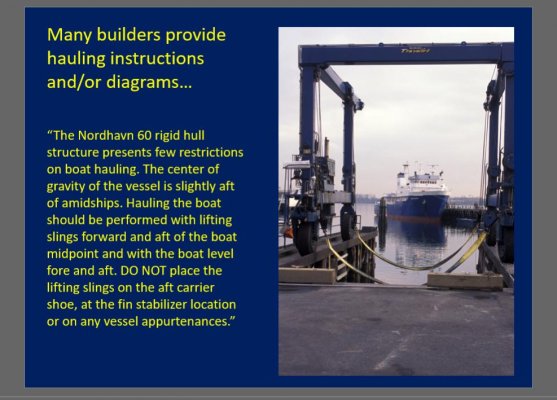

Most of those I work with, once again, provide a gravign document and instructions, all you need to do is ask; something too few hauling crews do in my experience. The attached images are from a presentation I delivered at the International Boat Builders Exhibition in 2019, on the subject of safely and properly hauling, blocking and launching vessels. These are hauling examples, block placement examples are also provided by many builders and TY28 already calls on boat manufacturers to provide this information,

"BOAT MANUFACTURER'S RESPONSIBILITIES

Boat manufacturers should provide information detailing the lifting points, blocking diagrams, and storage considerations appropriate to their boats, indicating which hauling equipment, blocking, and storage methods are appropriate, and which are not. For example, if the keel(s) of a boat cannot take the full weight, or if there are limits or restrictions about where blocking supports can be located, the boat manufacturer should provide this information.

Boat manufacturers should mark boat lifting points with a label or the international mark as illustrated in FIGURE 1. Boats may be lifted by several methods. Lifting points should be determined in consideration of hull structure that can support the loads, and running gear or appendages below the waterline that cannot sustain the weight imposed during lifting. Chines, rails, deck edges, and other projections that cannot sustain the loads imposed at lifting points should be identified.

Builders of boats that can be lifted by forks should consider constructing the boat to withstand the stresses involved when the boat is lifted according to the boat manufacturer's recommendations and hull markings. Builders should consider providing a diagram in the boat owner’s manual showing profile and transom views illustrating fork placement, minimum fork length, and structural support locations, and providing markings on the exterior of the boat to indicate the proper spacing of the forks."

"Blocking

Boat keels should be blocked as close to the ground as practical. Keel blocking should be used to support the weight of the boat, unless otherwise specified by the boat manufacturer. Keel blocking should be distributed to prevent high local loading. The blocking should be adequate to support the boat, taking the condition and slope of the ground, and the size, shape, weight, and condition of the boat into account. Use a minimum of two sets of keel blocking per boat. The blocking should be as large as practicable and appropriately sized for the boat. The minimum dimension measured fore and aft along the keel should be six inches (152 mm) nominal per block. If the blocking is over two tiers high, it should be cribbed. Cribbing height should not exceed 1.5 times the minimum base footprint dimension. Barrels, foam blocks, cinder blocks, and other masonry products not intended to bear weight should not be used for blocking (see TABLE 1 for minimum block dimensions); 12 in x 12 in (30.5 cm X 30.5 cm) blocks are usable in all cases."

Underline is mine.

Using the FAA-like "one cored hull damaged is too many", will drive the cost of recreational boat ownership into the realm of private aircraft ownership. With that approach, one engine that breaks down and leaves a vessel adrift is one too many, one bilge pump that fails and allows a vessel to sink is one too many. I'm simply not seeing wholesale failures in below the waterline cored hulls because of blocking issues. What I see far more of is saturated core, both above and below the waterline and as common, costly and potentially dangerous as that is, and in spite of the fact that the Standards include a "HULL STANDARDS" section, ABYC is silent on the subject, because it hasn't proven to be a problem that is causing loss of life.

I sit on several ABYC Project Technical Committees, these are the bodies responsible for writing and amending ABYC Standards. We are veritably inundated with requests for changes or new standards from genuinely concerned boat owners and industry pro's alike. While many of these requests have merit, the yard stick by which creation of a new standard is measured is, 'is anyone dying because of this?' The bar for amendments and additions to existing standards is somewhat lower, but the Council tries to avoid anything that is prescriptive. The process is both exhaustive and exhausting, with a range of competing interests weighing in. I spent approximately 5 full days this past year participating in committee Zoom meetings to hammer out a relatively small number of changes.

Having said all that, if your suggestions meet the above detailed guidelines, then I'd welcome the review and their adoption if deemed worthy by the PTC, there's definitely room for improvement in the world of hauling and blocking.

As far as TY28 Boat Lifting and Storage is concerned, it's unfortunate you didn't get your material in for the 2020 update, as that Technical Information Report (it's not a Standard) isn't due to be revisited for several years, here's the preface, "TY-28, Boat Lifting and Storage was first published in 1998. The ABYC Technical Board intended that the report would cover the most common types of lifting equipment and storage methods. TY-28 is currently limited to the equipment and methodology of most prevalent modern marinas and boat yard operations that utilize straddle lifts, fork lift equipment, boat stands, and similar storage equipment for boats on land storage. TY-28 was revised in 2014. The 2020 revision is the work of the Boat Service Project Technical Committee." Have you read TY28?

I can tell you from experience, unless you are familiar with the critique protocol for ABYC Standards, and unless you attend a Project Technical Committee meeting (they are open to the public), where you can elaborate on, and defend your recommended changes or additions, the debate is intentionally vigorous, the likelihood of them being adopted is very slim. Since it will be in 2026, you'll have time to prepare and plan to attend Standards Week.

For the benefit of Forum members who may not understand this, this section from the Standards describes the "performance" rather than prescriptive, approach...

PERFORMANCE APPROACH

As far as practicable, these standards and technical information reports are stated in terms of performance rather than design or descriptive characteristics and are not intended to preclude attainment of desired results by other means. This approach leaves maximum freedom to technical development and compliance with applicable regulations.

These standards are of general applicability, and there may be instances in which the particular use, configuration, or other characteristics of a specific boat, or classes of boats, may result in special requirements differing from the generally applicable standards. ABYC standards are not intended to conflict with mandatory governmental standards. Such mandatory standards must be followed as a minimum. ABYC standards may be different from mandatory standards when, in the opinion of the Council, good or desirable practices suggest that the ABYC advisory standards provide for features in addition to those required.

If it is impractical to determine the necessary performance characteristics of materials or devices, the material or device may be specified but with the inclusion of the phrase “… or other material/device which has been proved to be equally suitable.”

Requirements concerning the manufacturing or installation process shall usually be omitted in favor of tests to be made on the final product or installation. There are, nevertheless, some fields in which reference to the manufacturing process may be required. The choice between specifying by description or by performance is considered seriously as specification solely by performance may lead to complicated testing procedures of long duration and high cost.

Again, for Forum members who may not be familiar with ABYC, this article profiles the organization https://stevedmarineconsulting.com/...cht-Council-A-look-into-this-organization.pdf

Attachments

I just read the OP's latest and apparently last post on the subject. This is at least the second crack event. More to come. Regards.

The prior crack event to Jfrano's boat was a 4" crack midships and was repaired under warranty. There have been no other cracks publicly reported. Cook's boat had significant damage. It was not a mere crack.

RT has an excellent warranty policy that runs for 10 years and transfers to the second retail owner. It excludes

1) Any damage resulting from an accident or impact with another object

2) Any fiberglass boat that has been ... improperly lifted or trailered; improperly secured to a trailer

3) Damage caused by improper trailering or mismatching of a Ranger fiberglass boat to a trailer; or failure to properly secure the fiberglass boat to a trailer.

OP Dave Cook apparently has not filed a warranty claim, has not filed an insurance claim, and has not filed a civil suit, and apparently has not fixed the boat. Cook did acknowledge on Sep 2020 that "THE PERSONAL OPINIONS OF PEOPLE IN THE KNOW , IS THAT THE BOAT WAS PUT DOWN HARD ON A BLOCK"

His strategy for the last two years has been to post conspiracy theories on various forums claiming RT does not want him to see inside the hull because "the plant does not want the boat repaired from the inside as it is possible there are fiberglass defects inside that will come to light"

More to come?

Yes. More of the same.

STB

Guru

I don't know what to say about the tug situation, otherbthan I'm truly sorry the OP isn't out enjoying the water as he seemingly once had hoped he'd be.

W.r.t. the comparison of cored and solid hulls, I always find them hard without holding some constraint(s) constant.

Are we comparing hulls of the same thickness?

...or of the same weight per displaced volume?

...or of the same material costs, labor costs, or total costs?

...or same schedule-time to completion?

...or manufactured with samenlocal or global environmental impact?

...or....?

I suspect a cored hull would provider a greater margin of grounding or blocking safety than a corresponding solid hull under at least some among the above constraints.

W.r.t. the comparison of cored and solid hulls, I always find them hard without holding some constraint(s) constant.

Are we comparing hulls of the same thickness?

...or of the same weight per displaced volume?

...or of the same material costs, labor costs, or total costs?

...or same schedule-time to completion?

...or manufactured with samenlocal or global environmental impact?

...or....?

I suspect a cored hull would provider a greater margin of grounding or blocking safety than a corresponding solid hull under at least some among the above constraints.

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 3K

- Replies

- 40

- Views

- 3K