Panacea

Veteran Member

- Joined

- Aug 17, 2015

- Messages

- 88

- Location

- USA

- Vessel Name

- Panacea

- Vessel Make

- Marine Builders, Voyager 70

I've always had a thing for the old Gulf Star trawlers. Several months ago I found Reef Monkey, a 1975 Gulf Star 36 MKII for sale on craigslist and adopted her. She has twin Perkins 4-154 and a 12kw Northern Lights Genny. Mechanically, she is an alright condition. Cosmetically, she needs some love.

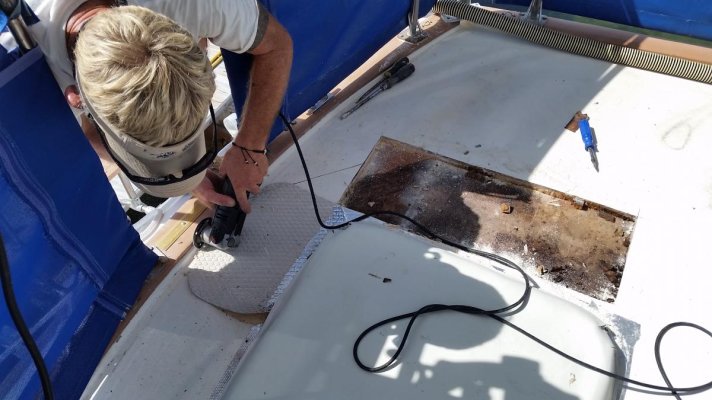

The teak toe rail and trim has been painted brown with house paint. The gel coat has a lot of crazing and stress cracks. There are quite a few leaks that need to be addressed. The deck is severely blistered in places due to Treadmaster non-skid mat holding moisture. Both air conditioning units don't work. The aft deck has a pretty severe soft spot. The swim platform is deteriorating. And at one point in her life she had a "professional" paint job that appears as if the paint was applied with a mop.

My goal is to do a practical restoration of the boat. Anywhere that I can avoid complication or reduce maintenance will get attention. I have always enjoyed reading project threads, so I I plan on posting updates in this thread as the project processes!

The teak toe rail and trim has been painted brown with house paint. The gel coat has a lot of crazing and stress cracks. There are quite a few leaks that need to be addressed. The deck is severely blistered in places due to Treadmaster non-skid mat holding moisture. Both air conditioning units don't work. The aft deck has a pretty severe soft spot. The swim platform is deteriorating. And at one point in her life she had a "professional" paint job that appears as if the paint was applied with a mop.

My goal is to do a practical restoration of the boat. Anywhere that I can avoid complication or reduce maintenance will get attention. I have always enjoyed reading project threads, so I I plan on posting updates in this thread as the project processes!

I could have used accellerator, but it effects flow when brushing so I don't like to use it.

I could have used accellerator, but it effects flow when brushing so I don't like to use it.