If you go with a NL, and you probably can't go wrong going that route it's a high quality product with stellar support, and you are ordering rather than buying one off a showroom floor (if there are any), ask for the following...

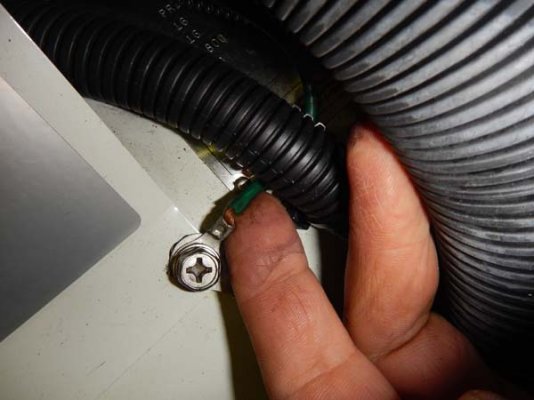

"Junction box ground should be larger, no less than one size smaller than the wire used to connect the gen to the vessel's panel"

Every NL J box ground wire is a #16, woefully inadequate for carrying fault current for even the smallest genset.

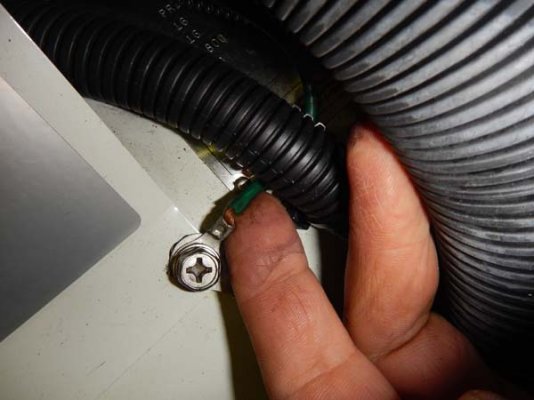

"The hole through which the boat's AC wires will pass, in the junction box, should be a standard knock out so an off the shelf cord grip can be used"

This is a non-standard size hole, making it very difficult to meet the ABYC requirement for wire immobilization in this area. You will need to give them the size cord grip you intend to use.

Both of these mods can be made when installing the genset if you are buying one that's already been built.

These requirements hold true for all gensets, some make provisions in the design to contend with them better than others.

Photos, a proper cord grip; no cord grip (just a bushing which is inadequate); the undersized J box ground; a properly sized j box ground.

"Junction box ground should be larger, no less than one size smaller than the wire used to connect the gen to the vessel's panel"

Every NL J box ground wire is a #16, woefully inadequate for carrying fault current for even the smallest genset.

"The hole through which the boat's AC wires will pass, in the junction box, should be a standard knock out so an off the shelf cord grip can be used"

This is a non-standard size hole, making it very difficult to meet the ABYC requirement for wire immobilization in this area. You will need to give them the size cord grip you intend to use.

Both of these mods can be made when installing the genset if you are buying one that's already been built.

These requirements hold true for all gensets, some make provisions in the design to contend with them better than others.

Photos, a proper cord grip; no cord grip (just a bushing which is inadequate); the undersized J box ground; a properly sized j box ground.