MichaelB1969

Guru

- Joined

- Oct 15, 2016

- Messages

- 679

- Location

- USA

- Vessel Name

- Speedy Charlotte

- Vessel Make

- Beneteau Swift Trawler 44

First off, for all those affected by the storm, my heart goes out to you.

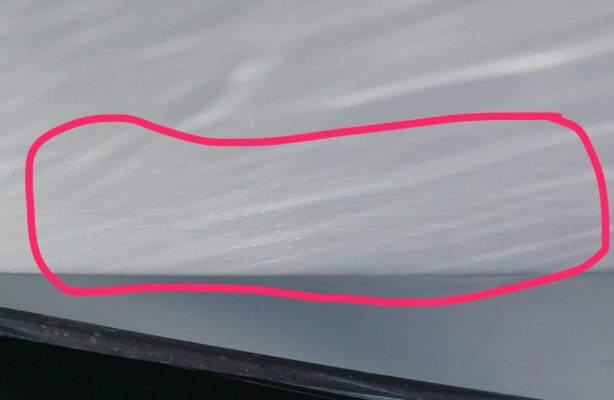

I've got a big area above the chine with gelcoat cracks. From the looks of it, seems like something impacted the center of this area, but I don't recall hitting anything that high above the chine. We would have noticed it in the water.

I did recently strike something under the water on two separate occasions a few weeks ago heading down to Monterey where we felt a thud and an accompanying sound beneath us. No idea what they were. But again, this was under the waterline for sure.

Any thoughts?

P.S. I still haven't talked about my diesel fuel episode from that trip where water started gushing up from the tank. I'm still traumatized. Need more time.

I've got a big area above the chine with gelcoat cracks. From the looks of it, seems like something impacted the center of this area, but I don't recall hitting anything that high above the chine. We would have noticed it in the water.

I did recently strike something under the water on two separate occasions a few weeks ago heading down to Monterey where we felt a thud and an accompanying sound beneath us. No idea what they were. But again, this was under the waterline for sure.

Any thoughts?

P.S. I still haven't talked about my diesel fuel episode from that trip where water started gushing up from the tank. I'm still traumatized. Need more time.