sunchaser

Guru

- Joined

- Apr 9, 2008

- Messages

- 10,196

- Location

- usa

- Vessel Name

- sunchaser V

- Vessel Make

- DeFever 48 (sold)

Codger

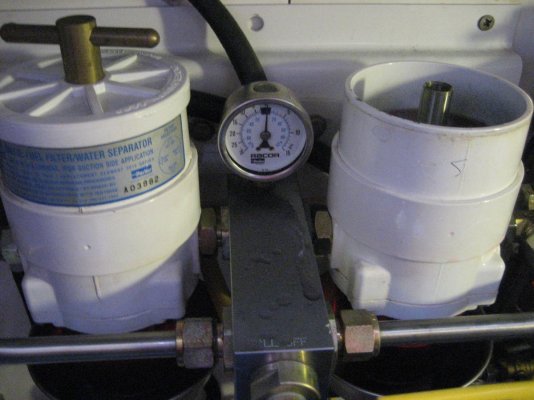

Do you have a fuel filter vacuum gauge read out at your helm? For some that is a nicety so that if vacuum increases to a "concern" number you can flip the valve to the other filter before the engine stumbles.

We've never had one iota of vacuum show up on our 900s. Which should be the case given our low fuel burn rate. On planing vessels using 15GPH+ per side, seeing a vacuum increase is understandable.

Do you have a fuel filter vacuum gauge read out at your helm? For some that is a nicety so that if vacuum increases to a "concern" number you can flip the valve to the other filter before the engine stumbles.

We've never had one iota of vacuum show up on our 900s. Which should be the case given our low fuel burn rate. On planing vessels using 15GPH+ per side, seeing a vacuum increase is understandable.