ORIF

Senior Member

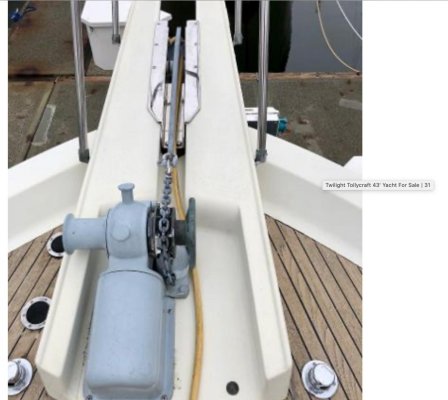

I've been having an issue with my chain rode chafing against the sides of my bow pulpit hawse channel (if that's the correct term).

Only occurs in high wind or current conditions when I can't keep it coming in straight.

I've been working on some designs to try to prevent this and after my 3rd iteration was wondering if anyone has a better design they could share.

Thanks,

Edward

Only occurs in high wind or current conditions when I can't keep it coming in straight.

I've been working on some designs to try to prevent this and after my 3rd iteration was wondering if anyone has a better design they could share.

Thanks,

Edward