BDofMSP

Guru

- Joined

- Sep 5, 2013

- Messages

- 905

- Location

- USA

- Vessel Name

- Gopher Broke

- Vessel Make

- Silverton 410 Sport Bridge

Odd question.

I need to adapt an M22 x 1.5 hole in my manifold to hold a 1/4" NPT stainless turbo boost pressure sensor. I have limited clearance and need to adapt to a 90 degree, so I would prefer to use an M22 (male) to 1/4 (female) bushing, and then a 1/4 to 1/4" 90 degree adapter.

Note - this thread adapter is called a bushing but it's not what I usually think of as a bushing. But we're going with it since that's what they called it. It's just a thread adapter.

I can find that bushing, but only in carbon steel. The 90 adapter is brass. Again the sensor is stainless.

I can find the bushing in brass, but only M22 to 1/8". I'd have to adapt up to 1/4 and I don't know how that would impact my pressure readings.

So do I care that the bushing is carbon steel? I'm assuming that manifold is cast iron? Or would I be better off using brass, but having to adapt from 1/8" to 1/4" for the sensor?

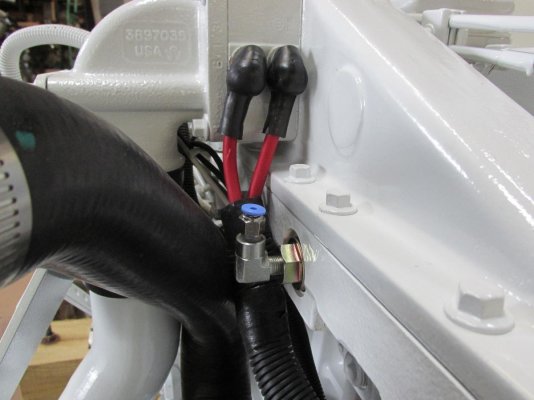

For the visual, I'm trying to replicate this piece (which I'd buy but it's 1/8 NPT instead of 1/4).

Thanks

BD

I need to adapt an M22 x 1.5 hole in my manifold to hold a 1/4" NPT stainless turbo boost pressure sensor. I have limited clearance and need to adapt to a 90 degree, so I would prefer to use an M22 (male) to 1/4 (female) bushing, and then a 1/4 to 1/4" 90 degree adapter.

Note - this thread adapter is called a bushing but it's not what I usually think of as a bushing. But we're going with it since that's what they called it. It's just a thread adapter.

I can find that bushing, but only in carbon steel. The 90 adapter is brass. Again the sensor is stainless.

I can find the bushing in brass, but only M22 to 1/8". I'd have to adapt up to 1/4 and I don't know how that would impact my pressure readings.

So do I care that the bushing is carbon steel? I'm assuming that manifold is cast iron? Or would I be better off using brass, but having to adapt from 1/8" to 1/4" for the sensor?

For the visual, I'm trying to replicate this piece (which I'd buy but it's 1/8 NPT instead of 1/4).

Thanks

BD

Attachments

Last edited: