Nomad Willy

Guru

Ken .. Ben .. Rick,

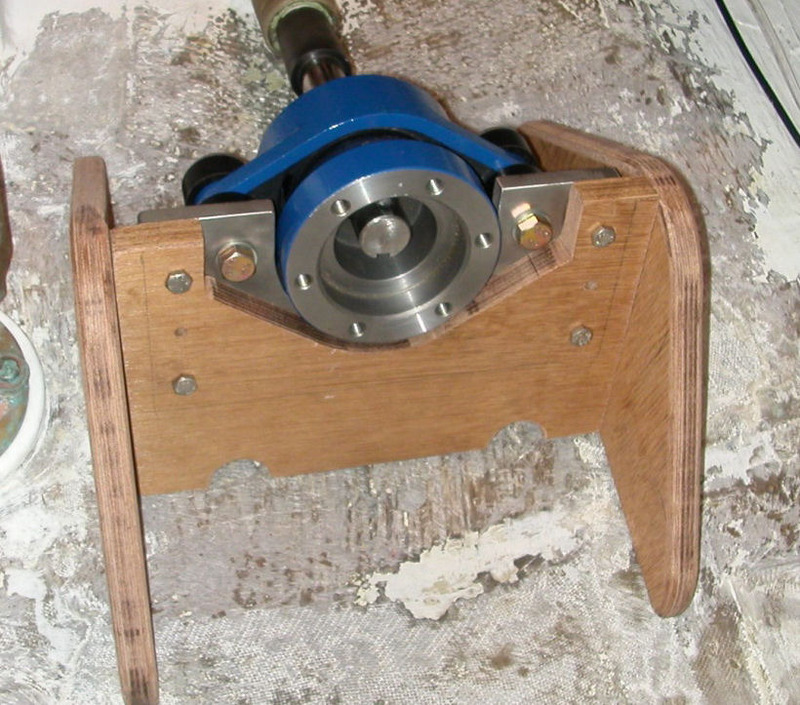

OK Rick. This is going to be a very efficient boat. Python Drive is a very good idea. That or Aqua Drive or perhaps there are others now. I did a Aqua Drive in my Albin. I had the smallest unit that only had two mounting ears. Four would have saved me lots of alignment grief. No way to adjust up-down pitch so needed to grind washers to assume the right angle as my mounting lay-up wasn't perfect. Need four ears IMO.

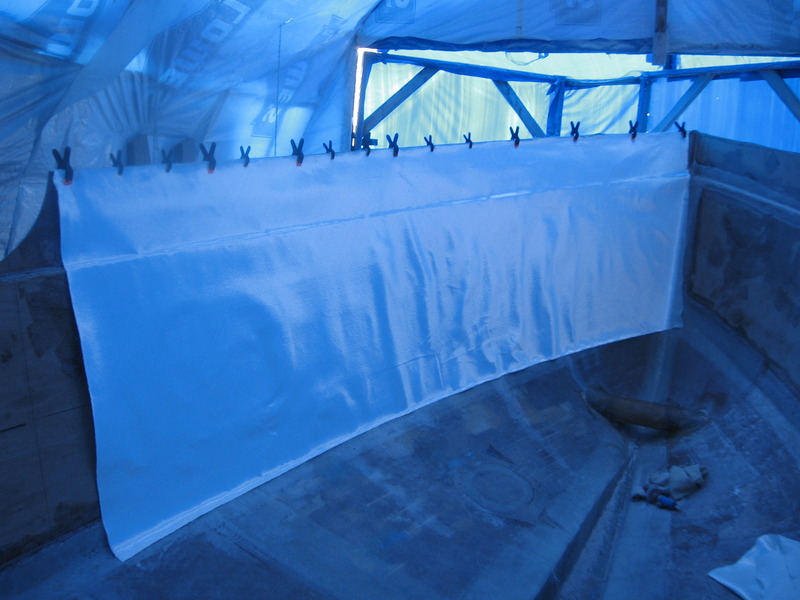

That smooth and easy rocker will guide the water back to the surface very gracefully. Wish most trawlers had an afterplane like that. Or even half like that as a SD. Gonna be a very nice boat Rick.

OK Rick. This is going to be a very efficient boat. Python Drive is a very good idea. That or Aqua Drive or perhaps there are others now. I did a Aqua Drive in my Albin. I had the smallest unit that only had two mounting ears. Four would have saved me lots of alignment grief. No way to adjust up-down pitch so needed to grind washers to assume the right angle as my mounting lay-up wasn't perfect. Need four ears IMO.

That smooth and easy rocker will guide the water back to the surface very gracefully. Wish most trawlers had an afterplane like that. Or even half like that as a SD. Gonna be a very nice boat Rick.

Couple of places I think I'll be able to use it later though. The clouds opened up so I had to call it quits.

Couple of places I think I'll be able to use it later though. The clouds opened up so I had to call it quits.