Regarding power production...

One of the differences between an LRC or FPB vs other boats is the amount of solar power panels on the boats. On the LRC 65, it is at least 5K watts. This is a game changer, especially compared to a sailboat where one is going to have to make some design choices to get around 1K watts.

With 5KW+ of solar panels, the boat we are planning will have surplus power 10 months of the years. LOTS of surplus power. There is so much power it is influencing fridge/freezer selection. The problem months would be in northern Europe in December and January, but even then, the Victron calculator says we might be able to produce the power needed via solar. It would be close though.

Cooling HVAC not included.

Having said that, it seems that some cooling could be done using power generated/stored by solar.

As mentioned by other posters, correctly loading the engine is important and one does need some HP overhead for sea state, wind, power production and/our hydraulics if used.

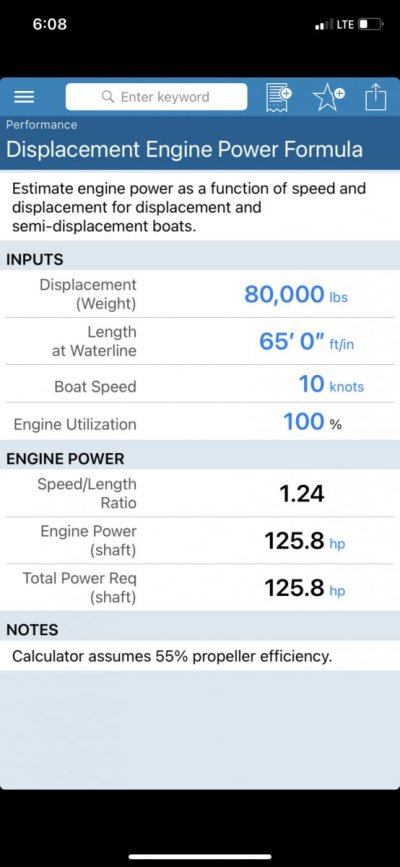

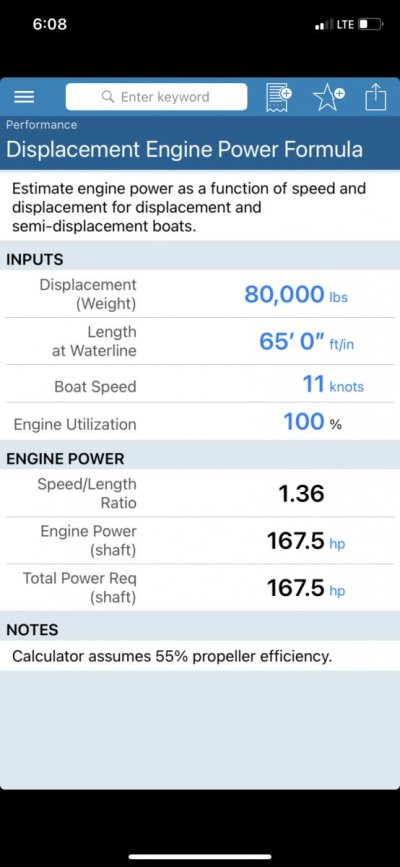

Voyaging Under Power by Bebee has a method for calculating needed engine HP that seems to be in the ball park for boats I have looked at and where I have the information to verify his formula.

I would prefer to not have twin engines but I want two ways to move the boat. I would prefer one engine and a decent sail plan but that has some design choices that are problematic as well.... <sigh>

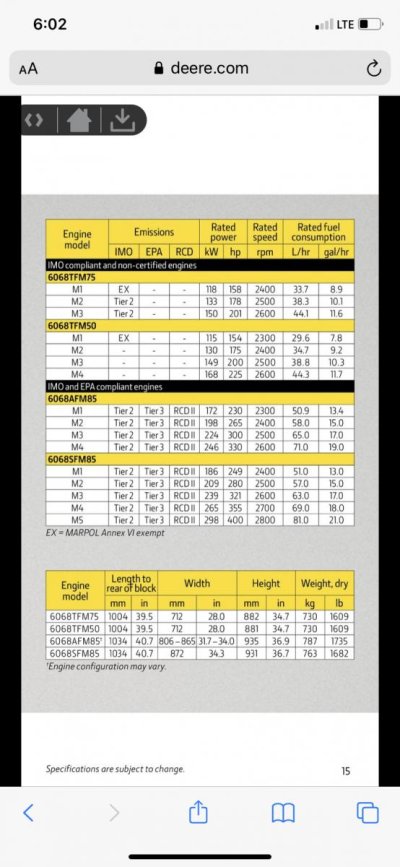

An LRC-65, with twin engines,

, can have smaller HP engines, with alternators that can help provide the proper load. I have yet to find a definitive definition of what a proper load is on a modern diesel but I think I can come close with the right choices of alternators. Pretty sure I can get there but worry about the structural loading on the engine for belt driven alternators. Flip side, is I don't see the need to produce that much power from the engines due the solar power production, except for that pesky cooling requirement.

Then there are PTO or hydraulic alternators/generators... Choice, choices, choices.

We really do not want a generator, and with the possible exception of the need to cool the boat, I do not see the need due to the amount of solar that can be put on the boat along with twin engines running higher output alternators.

Twin engines also allows the boat to be dried out which is an interesting ability. Tis a bunch of design choices. Choices, choices, choices.

:lol:

Later,

Dan