Ftbinc

Senior Member

- Joined

- Sep 12, 2016

- Messages

- 138

- Vessel Name

- Oma

- Vessel Make

- Kadey Krogan\Manatee

Hi all

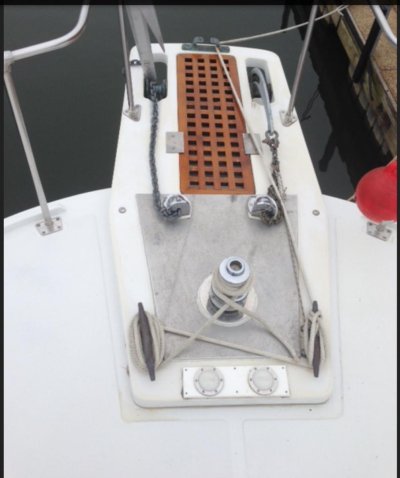

the next project is to fix the platform the windlass was on. The platform was leaking and the inner foam was nasty. I have opened up the deck underneath the teak strips where the windlass was mounted. I will re-glass both the cavity and the deck.

What should I fill the space with? What kind of foam before I reglass the deck? I’m open to ideas

Thanks in advance

Paul

KK Manatee Oma

the next project is to fix the platform the windlass was on. The platform was leaking and the inner foam was nasty. I have opened up the deck underneath the teak strips where the windlass was mounted. I will re-glass both the cavity and the deck.

What should I fill the space with? What kind of foam before I reglass the deck? I’m open to ideas

Thanks in advance

Paul

KK Manatee Oma