O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,868

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

- I think on-boat polishing systems are highly over-rated. I just don't think they create enough agitation, or draw from low enough in most tanks to address the settled crud at the bottom, and that's what you really need to polish out. Any suspended crud will get filtered out very effectively by the main filters.

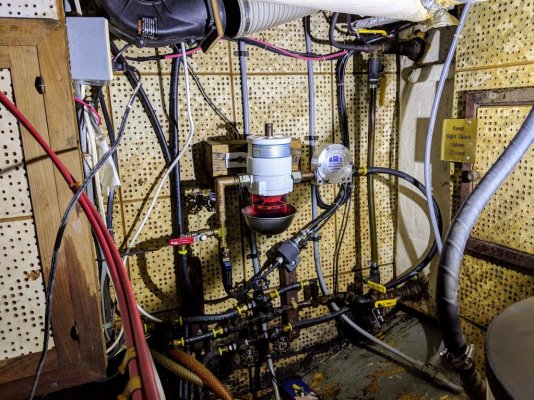

While I would agree with you in normal cruising conditions, when I'm rolling in 3 to 4' beams seas, everything that can get stirred up, will. The other factor is flow rate. At normal cruise, my lift pump flow rate (not fuel consumption) is about 20 GPH. The fuel polisher is about 180 GPH. I typically only polish the starboard side tank that feeds the engine and generator, when sea conditions would be stirring up any tank sediment. All fuel is loaded in the port side tank and polished as it's transferred.

The other nice feature on my setup is that fuel is returned at the opposite end (10' away) from where it's drawn, which should help to move all the fuel toward the polisher pickup.

Ted

Last edited: