cks

Senior Member

- Joined

- Sep 27, 2020

- Messages

- 192

- Location

- USA

- Vessel Name

- Silver Lining

- Vessel Make

- 2003 42’ Grand Banks Europa

Follow up from a previous post regarding my leaking water tank.

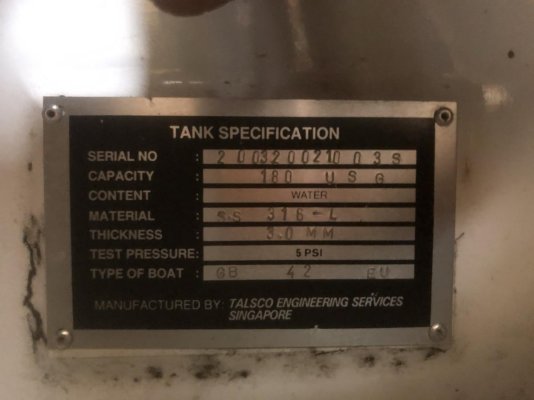

Due to the slight upward pitch of the boat, bilge water in the forward portion of the boat collects towards the rear of the 180 galling tank. The shaped tank is mounted just on the other side of the forward engine room bulkhead and under 5’ of the cabin sole. Even if you completely dry the bilge there is water back underneath the tank. As we all know, salt water is not your friend.

I believe this water situation has contributed to the degradation of a 3mm ( Approx 1/8”) 316 stainless steel tank. The operative word to a stainless steel tag is that it stains less. Otherwise it would’ve been called stain proof steel.

There is no easy access to the underside of the tank. There is no access to the sides of the tank. Since I’m working “blind” I created a water trace with uranine dye strips. I was able to push this test paper almost all the way under the tank, less 6” which is due to a wood support under the aft portion of the tank. Taking this 6 inches into consideration I have determined that the leak is 18” in which is in line with the baffle location. My hypothesis is the bottom starboard side weld of the baffle has developed a fairly good sized pinhole. (dropping 50 gallons/day)

I have marveled about how well designed he Europa is. The attention to detail, etc. The only real fail in the design is the water tanks and it has bitten me in the butt. Even the fuel tanks can be essentially cut out and replaced. Not the water tanks. The tank is mounted between the two forward at the stringers. If you look closely in your engine room you will see these two stringers to which your engines are mounted to. I’ve never paid attention as you go forward towards the bulkhead, the stringers widens from around 24” to 37” to accommodate the water tanks under the cabin.

To attack this problem I have cut open a 16“ x 16“ opening in the forward bulkhead of the engine room just below the electrical distribution panel. Tomorrow I will cut a 12” hole to gain access and visibility to the baffle.

Our course of action will be completely dependent on what we uncover.. I’ll add to this post as I move forward.

To it insure I never have water in this part of the bilge again I intend on building a wooden damn to prevent water for getting back there. I’ll most likely use epoxy. My suggestion to other Europa owners, check your forward and bilge pump. If you see ANY water in that part of the bilge please be mindful that there is a lot more that you don’t see and it may eventually compromise the tank. I urge you to take note. Having your main 180 gallon tank drop all its water in 3 days is a very sinking feeling, will cause undo obsession and angst.

Due to the slight upward pitch of the boat, bilge water in the forward portion of the boat collects towards the rear of the 180 galling tank. The shaped tank is mounted just on the other side of the forward engine room bulkhead and under 5’ of the cabin sole. Even if you completely dry the bilge there is water back underneath the tank. As we all know, salt water is not your friend.

I believe this water situation has contributed to the degradation of a 3mm ( Approx 1/8”) 316 stainless steel tank. The operative word to a stainless steel tag is that it stains less. Otherwise it would’ve been called stain proof steel.

There is no easy access to the underside of the tank. There is no access to the sides of the tank. Since I’m working “blind” I created a water trace with uranine dye strips. I was able to push this test paper almost all the way under the tank, less 6” which is due to a wood support under the aft portion of the tank. Taking this 6 inches into consideration I have determined that the leak is 18” in which is in line with the baffle location. My hypothesis is the bottom starboard side weld of the baffle has developed a fairly good sized pinhole. (dropping 50 gallons/day)

I have marveled about how well designed he Europa is. The attention to detail, etc. The only real fail in the design is the water tanks and it has bitten me in the butt. Even the fuel tanks can be essentially cut out and replaced. Not the water tanks. The tank is mounted between the two forward at the stringers. If you look closely in your engine room you will see these two stringers to which your engines are mounted to. I’ve never paid attention as you go forward towards the bulkhead, the stringers widens from around 24” to 37” to accommodate the water tanks under the cabin.

To attack this problem I have cut open a 16“ x 16“ opening in the forward bulkhead of the engine room just below the electrical distribution panel. Tomorrow I will cut a 12” hole to gain access and visibility to the baffle.

Our course of action will be completely dependent on what we uncover.. I’ll add to this post as I move forward.

To it insure I never have water in this part of the bilge again I intend on building a wooden damn to prevent water for getting back there. I’ll most likely use epoxy. My suggestion to other Europa owners, check your forward and bilge pump. If you see ANY water in that part of the bilge please be mindful that there is a lot more that you don’t see and it may eventually compromise the tank. I urge you to take note. Having your main 180 gallon tank drop all its water in 3 days is a very sinking feeling, will cause undo obsession and angst.