You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Air entering raw water strainer.

- Thread starter Scoid

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

THis caught my attention, so I too looked-up the SVS series.

https://www.groco.net/media/file/file/s/v/svs-series.pdf

It has the old-school tapered plug style of valve. I have no idea why it would leak-down, or where the water would go, but I agree with Ted's guidance here. Given the amount of futzing the OP has tried with no success, time to hit the reset button.

BTW - I am seeing many people using Groco Flanged NPT>NPS Adapters with a ball valve instead of a traditional all-in-one flanged seacock. Allows the ball valve to be easily replaced needed, which is admittedly rare.

https://www.groco.net/products/valves-seacocks/flanged-valves/ibvf-flange-adaptor

Peter

Great lead on the adapter! Those should have been invented sooner.

I have not done it personally but have read of others using aerosol shaving cream looking for vacuum leaks. While underway spray different areas to see if there is a change.

I’ll try it. Thanks!

firstbase

Guru

- Joined

- Nov 6, 2016

- Messages

- 1,644

- Location

- United States

- Vessel Name

- Black Eyed Susan

- Vessel Make

- Grand Banks 42' Classic

No. But I have lubed it through the drain by putting a zerk there. I lubed it until grease came out the t-handle threads. The boats in the water. I might have a diver cup the hole while I open up the valve but if the rubber cylinder is shot I might be in trouble.

Yes, the rubber cones are impossible to find. I talked to Groco when working on mine and they were no help with finding a couple of replacements. I lightly sanded down the hump on each and they seemed to be fine. Agai, finally tired of the situation and replaced with the adapter and a seacock. The strainer is the nlet icover on the hull.

Guilhem

Veteran Member

- Joined

- Apr 15, 2021

- Messages

- 58

- Vessel Name

- Octant

- Vessel Make

- Grand Banks 42 MY

This is not what the Guidi installation guide says. Page 7: https://www.guidisrl.it/wp-content/uploads/2020/06/Water-intakes-and-scoops.pdfIs the scoop facing forward or aft? It's counterintuitive but they are supposed to face aft. Most of them get installed backwards. Facing aft they resist bubbles or anything else but water getting sucked in.

Or do I misunderstand what you meant by "scoop facing aft"?

If this only happens while underway I can almost guarantee that you're getting bubbles along the hull that are going up into the strainer. Had the same problem on MOJO. The best solution is to simply drill and tap the top of the strainer for a 1/8" hose barb. Install the barb and run a 1/8" hose up high in the boat (higher than the waterline will ever be even when heeled substantially). Leave end of the hose open to the atmosphere. Any bubbles coming into the strainer will immediately go out the hose on top. Problem solved. I ran MOJO for 20 years with this solution...

Bonedoc

Veteran Member

- Joined

- Nov 13, 2020

- Messages

- 88

- Vessel Name

- DOÑA

- Vessel Make

- Ellis 28

I wound second a new or temporary substitute Grocco strainer. Also a motor under load may not mimic running at higher RPM’s dockside particularly if this is a diesel.

Bduffey

Member

I had a similar issue. It was a blockage right in the input of the strainer. It was not visible until you looked into the water input port and not inside the strainer itself. The very high suction from the raw water pump attempting to keep the volume of water flow normal was pulling in air from the lid.

There was no leakage/drips of water ever. Once the blockage (tight ball of weeds that got stuck in the input) was resolve, all was well. It allowed some water flow through but required the super high suction to do so. The reason it only happens when running was the increased suction from increased RPM. That caused enough suction to start pulling in small amounts of air from around the strainer lid that normally would never do so.

Take a look, maybe it is the same thing. It is an easy fix. It could also be the thru hull partially blocked. If there is an input hose before the strainer it could be internally blocked or partially collapsed inside creating this odd issue.

Good luck

There was no leakage/drips of water ever. Once the blockage (tight ball of weeds that got stuck in the input) was resolve, all was well. It allowed some water flow through but required the super high suction to do so. The reason it only happens when running was the increased suction from increased RPM. That caused enough suction to start pulling in small amounts of air from around the strainer lid that normally would never do so.

Take a look, maybe it is the same thing. It is an easy fix. It could also be the thru hull partially blocked. If there is an input hose before the strainer it could be internally blocked or partially collapsed inside creating this odd issue.

Good luck

I had a similar issue. It was a blockage right in the input of the strainer. It was not visible until you looked into the water input port and not inside the strainer itself. The very high suction from the raw water pump attempting to keep the volume of water flow normal was pulling in air from the lid.

There was no leakage/drips of water ever. Once the blockage (tight ball of weeds that got stuck in the input) was resolve, all was well. It allowed some water flow through but required the super high suction to do so. The reason it only happens when running was the increased suction from increased RPM. That caused enough suction to start pulling in small amounts of air from around the strainer lid that normally would never do so.

Take a look, maybe it is the same thing. It is an easy fix. It could also be the thru hull partially blocked. If there is an input hose before the strainer it could be internally blocked or partially collapsed inside creating this odd issue.

Good luck

Thanks. Nothing between the strainer and the valve. I’ve also thought it could be something in the thru hill but really don’t want to check it without hauling out be cause the rubber cylinder could be damaged.

Because there are no more cylinders I’ve decided to replace the strainer as sooner or later it will need a new cylinder. This would be a piece of cake if Groco made these available.

Have the exact same strainers on my GB 49. There is supposed to be a plastic washer.. probably Teflon.. under the big tightening nut on top… do you have one?

Yup. Replaced it three times.

Cavitation is not always air mixing with water . It is often pressure change that boils water making air. Also just because you do not see water leaking doesn’t mean you do not have an air leak. Under vacuum air can actually come through a hose and for sure come through a hose barb. We see this often without ever seeing a drop of water .

I'm no physicist but cavitation doesn't "make air", it creates a void or vapor filled cavity, hence the name, and that void collapses the moment the vacuum drops. The voids would only remain if the vacuum remained, and that can't occur at rest, assuming it's happening at all. Lowering the pressure on a liquid does lower the boiling point, but again once the pressure returns to normal, the voids collapse.

This does not occur in any raw water strainer I have ever seen (I have seen it occur in polishing system filters), if the vacuum was high enough to get the water within the strainer to "boil", at the very least the impeller would wear out very quickly, and/or the engine would be overheating because it would be starving for water.

This sounds like an air leak in plumbing between the strainer and the hull, a leak in the strainer housing, or ingestion of air bubbles from the bottom. A scoop will make no difference, it helps with prime but will scoop in water or air bubbles alike.

I'm no physicist but cavitation doesn't "make air", it creates a void or vapor filled cavity, hence the name, and that void collapses the moment the vacuum drops. The voids would only remain if the vacuum remained, and that can't occur at rest, assuming it's happening at all. Lowering the pressure on a liquid does lower the boiling point, but again once the pressure returns to normal, the voids collapse.

This does not occur in any raw water strainer I have ever seen (I have seen it occur in polishing system filters), if the vacuum was high enough to get the water within the strainer to "boil", at the very least the impeller would wear out very quickly, and/or the engine would be overheating because it would be starving for water.

This sounds like an air leak in plumbing between the strainer and the hull, a leak in the strainer housing, or ingestion of air bubbles from the bottom. A scoop will make no difference, it helps with prime but will scoop in water or air bubbles alike.

I originally thought some sort of agitation or cavitation was taking place caused by something flapping or partially blocking the thru hull. But it’s pretty obvious now that’s not going to be the case.

So, the only thing that could be leaking air between the strainer and the thru hull is the valve. More specifically, the rubber cylinder.

Since the cylinders are no longer available, I’ve decided to replace the whole system with a more modern design.

Thanks to everyone for your help, experience, and suggestions.

SteveI'm no physicist but cavitation doesn't "make air", it creates a void or vapor filled cavity, hence the name, and that void collapses the moment the vacuum drops. The voids would only remain if the vacuum remained, and that can't occur at rest, assuming it's happening at all. Lowering the pressure on a liquid does lower the boiling point, but again once the pressure returns to normal, the voids collapse.

This does not occur in any raw water strainer I have ever seen (I have seen it occur in polishing system filters), if the vacuum was high enough to get the water within the strainer to "boil", at the very least the impeller would wear out very quickly, and/or the engine would be overheating because it would be starving for water.

This sounds like an air leak in plumbing between the strainer and the hull, a leak in the strainer housing, or ingestion of air bubbles from the bottom. A scoop will make no difference, it helps with prime but will scoop in water or air bubbles alike.

I'm no physicist either but I do believe that there is a phenomenon that is similar to cavitation called "degassing" where dissolved gases come out of the liquid when the liquid experiences reduced pressure. If not mistaken this is what happens when a carbonated drink bottle is opened. The pressure is reduced and the didolved gas escapes as bubbles. In that case they do not redisolve unless subjected to increased pressure so a vapor pocket is formed and is evident.

Flow through a restriction causes the reduction in pressure.

In the case of the strainer a restriction could be causing dissolved air to come out of the water as small bubbles?

FWIW: Had this on 2 GB's, 42 & 46, off and on. All temps stayed within normal, measured with IR. Impellers changed every 500 hours, showed no abnormal symptoms or wear and often went in the box as spares. Had no resultant issues while air was evident, occasionally. Took no special steps to chase it.

diver dave

Guru

- Joined

- Jan 13, 2017

- Messages

- 2,570

- Location

- United States

- Vessel Name

- Coquina

- Vessel Make

- Lagoon 380

….

About the only thing I can figure is that there is cavitation happening at the intake. Had a diver check it. Couldn't see anything.

…..

Thanks!

Need to have the diver witness this at 7 kts[emoji15]

Full power at the dock does move water but no bow wave right?

Steve

I'm no physicist either but I do believe that there is a phenomenon that is similar to cavitation called "degassing" where dissolved gases come out of the liquid when the liquid experiences reduced pressure. If not mistaken this is what happens when a carbonated drink bottle is opened. The pressure is reduced and the didolved gas escapes as bubbles. In that case they do not redisolve unless subjected to increased pressure so a vapor pocket is formed and is evident.

Flow through a restriction causes the reduction in pressure.

In the case of the strainer a restriction could be causing dissolved air to come out of the water as small bubbles?

Don:

I thought for a while before writing that response, because I know that dissolved gas can be extracted from liquid, if enough vacuum is present, but I don't know enough about the physics of that to say whether or not it can happen here. You can get water to boil at room temperature if you apply enough a vacuum, but those "bubbles" are water vapor, not dissolved air from the water.

I suppose my 30+ year marine gearhead gut is telling me that just doesn't happen in strainers, I've never seen it, so why is this one different?

SteveDon:

I thought for a while before writing that response, because I know that dissolved gas can be extracted from liquid, if enough vacuum is present, but I don't know enough about the physics of that to say whether or not it can happen here. You can get water to boil at room temperature if you apply enough a vacuum, but those "bubbles" are water vapor, not dissolved air from the water.

I suppose my 30+ year marine gearhead gut is telling me that just doesn't happen in strainers, I've never seen it, so why is this one different?

Again I will confess / reinforce I'm not sure of the physics here but my thinking is...

I agree it takes extreme vacuum to cause change of state (boiling) from liquid to vapor. I don't think that is required to get dissolved gas to come out of the liquid but rather only a reduction of pressure.

I think of the carbonated beverage... no vacuum reqd only a reduction of applied pressure. When beverage bottle opened pressure is reduced and gas comes out of solution. I dont know the Pressure in champagne but that's a similar situation... pressure released / reduced and gas comes out.

If starting at 1.0 atm (air/O2 dissolved in seawater) wouldn't a small reduction of P cause some to come out of solution? Flow through a restriction causes a drop in pressure. Doesn't happen at lower RPMs but underway and higher RPM higher flow more P drop after a restriction.

I guess flow is RPM dependant so if it doesn't happen at the dock at normal operating RPM it would shoot a hole in my theory.

STB

Guru

So, my thinking...very, very, very back of the envelope, e.g. not super correct. And from another "Most definitely not a physicist or that kind of engineer".

There are a lot of forces acting upon the water, including the pump that lifts it out of the water through suction, e.g. pressure reduction.

I'm not sure how many feet of head a raw water pump can handle, maybe 10 feet? All things being equal, that's probably ~~~~4.5psi (considering the weight of a 1" column of water 10 ft high). If the water is being drawn from 3 feet below the water line, maybe that's another ~~~~~1.5psi difference. Maybe ~~~~~~~6psi is ~~~~~~~2/5 ATM.

At the temperature ranges we are talking about every ~~~~1ATM pressure drop probably can allow about ~~~~~~2% of the water's volume to deaerate as gas. So, maybe the pump, itself, can cause ~~~~~4/5% of the water's volume to deaereate as gas on the suction side. (Solubility of Air in Water)

What is the flow rate? ~~~~~~~10gpm? If the gas just jumped right out of the water, that might be ~~~~~~10oz/min of deaeration.

But, we aren't typically filling our strainers with air, never mind that quickly. Is this much gas really deaerating? And, if so, where is it going?

Let's think about Bacchus's soda bottle example. Think about how slowly the gas comes out of the soda once it is opened. Fizz, fizz fizz. Snap. Crackle pop. Minutes to hours, right? Air is a mix of gasses, not just CO2. So, the comparison only goes so far. Nitrogen and oxygen don't like to dissolve in water, or coming jumping out of water, nearly as much as CO2. So, putting numbers on this doesn't make sense. I mention it only to illustrate the idea that we've all probably noticed that the gas doesn't come out of solution instantly when the pressure changes.

It just isn't easy for bubble to form from dissolved gas. The molecules need to come together to form enough of a bubble to be mobile. A small number of molecules is relatively suspended in the fluid, acting largely as part of the fluid, with the fluid.

So, where does this leave us? There just isn't much air in the water to begin with, very little wants to come out, and much of that which does want to come out just doesn't have time to deaerate between the time it is under suction on the intake side of the pump and under pressure on the discharge side of the pump. And, even much of what does is in the form of very small bubbles that mostly move with the flow of the water.

Now, let's think about freshwater. Due to the reduced salinity (dissolved solids), it carries ~20% more air by volume than saltwater. Do those poor freshwater boaters suffer from bubble filled strainers? Or have a different configuration with higher-volume/lower-pressure suction sides? I don't think I've seen that (But, heck, I've got a new business idea....)

My take is that there is just too little of a pressure difference to cause enough air to come out of solution and suspension quickly enough in the few feet of hose before pressure is re-established and it ultimately can off gas into atmospheric air on the discharge side of things.

Bernoulli flow might add to the suction a bit by pulling in the opposite direction as the pump. But, I don't think it is going to move the needle enough to change things.

And, even if the boat scoop is installed to help the speed of the boat push water into the system, that won't really change things much, right? Where is the pressurized water going to suddenly find a bunch more gas in the minimal distance and fraction of a second, at best, before it gets shoved into the thru hull and want to give it up, not take it in?

I'm not a physicist, either. Not even close. But, I've never seen gas accumulate by suction in a strainer -- and I've seen some really clogged intakes and some boats moving at a really good clip with HVAC, gensets, and engines running without air. And, I can think of a lot of reasons what that is probable the case (see above).

I just don't see by intuition or estimation how cavitation or deaeration can possibly explain this situation.

There are a lot of forces acting upon the water, including the pump that lifts it out of the water through suction, e.g. pressure reduction.

I'm not sure how many feet of head a raw water pump can handle, maybe 10 feet? All things being equal, that's probably ~~~~4.5psi (considering the weight of a 1" column of water 10 ft high). If the water is being drawn from 3 feet below the water line, maybe that's another ~~~~~1.5psi difference. Maybe ~~~~~~~6psi is ~~~~~~~2/5 ATM.

At the temperature ranges we are talking about every ~~~~1ATM pressure drop probably can allow about ~~~~~~2% of the water's volume to deaerate as gas. So, maybe the pump, itself, can cause ~~~~~4/5% of the water's volume to deaereate as gas on the suction side. (Solubility of Air in Water)

What is the flow rate? ~~~~~~~10gpm? If the gas just jumped right out of the water, that might be ~~~~~~10oz/min of deaeration.

But, we aren't typically filling our strainers with air, never mind that quickly. Is this much gas really deaerating? And, if so, where is it going?

Let's think about Bacchus's soda bottle example. Think about how slowly the gas comes out of the soda once it is opened. Fizz, fizz fizz. Snap. Crackle pop. Minutes to hours, right? Air is a mix of gasses, not just CO2. So, the comparison only goes so far. Nitrogen and oxygen don't like to dissolve in water, or coming jumping out of water, nearly as much as CO2. So, putting numbers on this doesn't make sense. I mention it only to illustrate the idea that we've all probably noticed that the gas doesn't come out of solution instantly when the pressure changes.

It just isn't easy for bubble to form from dissolved gas. The molecules need to come together to form enough of a bubble to be mobile. A small number of molecules is relatively suspended in the fluid, acting largely as part of the fluid, with the fluid.

So, where does this leave us? There just isn't much air in the water to begin with, very little wants to come out, and much of that which does want to come out just doesn't have time to deaerate between the time it is under suction on the intake side of the pump and under pressure on the discharge side of the pump. And, even much of what does is in the form of very small bubbles that mostly move with the flow of the water.

Now, let's think about freshwater. Due to the reduced salinity (dissolved solids), it carries ~20% more air by volume than saltwater. Do those poor freshwater boaters suffer from bubble filled strainers? Or have a different configuration with higher-volume/lower-pressure suction sides? I don't think I've seen that (But, heck, I've got a new business idea....)

My take is that there is just too little of a pressure difference to cause enough air to come out of solution and suspension quickly enough in the few feet of hose before pressure is re-established and it ultimately can off gas into atmospheric air on the discharge side of things.

Bernoulli flow might add to the suction a bit by pulling in the opposite direction as the pump. But, I don't think it is going to move the needle enough to change things.

And, even if the boat scoop is installed to help the speed of the boat push water into the system, that won't really change things much, right? Where is the pressurized water going to suddenly find a bunch more gas in the minimal distance and fraction of a second, at best, before it gets shoved into the thru hull and want to give it up, not take it in?

I'm not a physicist, either. Not even close. But, I've never seen gas accumulate by suction in a strainer -- and I've seen some really clogged intakes and some boats moving at a really good clip with HVAC, gensets, and engines running without air. And, I can think of a lot of reasons what that is probable the case (see above).

I just don't see by intuition or estimation how cavitation or deaeration can possibly explain this situation.

STB

You may very well be correct and I'm all wet. Just sort of thinking outloud and writing it down... no strong technical proof behind it.

My only reaction is there must be disolved air or O2... otherwise the fish would all die... right? Wave action, especially white caps keep at least the surface water aerated and it must disperse to keep fish alive at depths?? Now I'm really getting out of my wheel house... lol

You may very well be correct and I'm all wet. Just sort of thinking outloud and writing it down... no strong technical proof behind it.

My only reaction is there must be disolved air or O2... otherwise the fish would all die... right? Wave action, especially white caps keep at least the surface water aerated and it must disperse to keep fish alive at depths?? Now I'm really getting out of my wheel house... lol

psneeld

Guru

Is the scoop facing forward or aft? It's counterintuitive but they are supposed to face aft. Most of them get installed backwards. Facing aft they resist bubbles or anything else but water getting sucked in.

I believe facing aft is for grannies, NOT main propulsion.

Nick F

Guru

- Joined

- Sep 2, 2020

- Messages

- 598

- Location

- Canada

- Vessel Name

- Callisto

- Vessel Make

- 1974 Grand Banks 42 Classic, Hull 433

If this only happens while underway I can almost guarantee that you're getting bubbles along the hull that are going up into the strainer. Had the same problem on MOJO. The best solution is to simply drill and tap the top of the strainer for a 1/8" hose barb. Install the barb and run a 1/8" hose up high in the boat (higher than the waterline will ever be even when heeled substantially). Leave end of the hose open to the atmosphere. Any bubbles coming into the strainer will immediately go out the hose on top. Problem solved. I ran MOJO for 20 years with this solution...

MOJO - I like your approach! Any interior leak is unlikely to change due to being underway.

However, this said, if the cause is indeed air bubbles from the motion, why did it only start to happen a few months ago? Has anything been changed on the exterior hull forward of the intake?

For further diagnosis, install a clear plastic hose between the thru-hull and the strainer and watch for bubbles.

Keep us posted.

STB

Guru

STB

You may very well be correct and I'm all wet. Just sort of thinking outloud and writing it down... no strong technical proof behind it.

My only reaction is there must be disolved air or O2... otherwise the fish would all die... right? Wave action, especially white caps keep at least the surface water aerated and it must disperse to keep fish alive at depths?? Now I'm really getting out of my wheel house... lol

There is most definitely dissolved air, including all of the major gases in air, most especially N2 and O2.

And, water's ability to maintain them in solution does depend upon temperature, pressure, salinity, etc.

And, changes in those parameter can cause the gases to come back out of solution.

The only bits where I am estimating differently than you, I think, are how much gas volume the attendant changes in condition would cause to want to come out of solution, how quickly they could come out of solution under the conditions, and how quickly the free gas could form bubbles large enough to bubble out vs remain in suspension and move with the water.

I don't really know the answers to these question. I'm not that type of scientist or engineer. Just like you, I'm guesstimate and thinking aloud.

You've been around the forum long enough to know that I get the model right enough sometimes and not right enough sometimes (and the later at night I post, the less likely my thinking is to be sensible, never mind right!)

I didn't mean to suggest that O2 and N2 don't dissolve in water...just that they don't do so nearly as well as CO2, which is why soda is carbonated and nitrogenated drinks have a much softer mouth feel. (O2 is flammable and would additionally be a bad choice for beverages for that reason.)

Last edited:

Keep us posted.

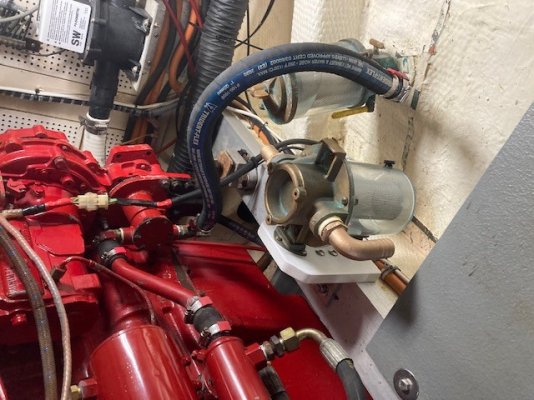

For anyone who might be interested, here's what I did......

I used a piece of 3/4" solid red oak and attached it to the main stringer with a 1/4" thick aluminum angle using 5/6" x 1" lag screws and 3M 4200. The top of the aluminum cap on the stringer is only about 1/8 to 3/16" thick. Below that is fiberglass and then a long steel plate (into which the motor mounts are bolted). I had to put spacers on the lag bolts because they were hitting the steel plate.

I replaced the SVS with an ARG I had sitting around.

I had the thru replaced at the yard. They were able to use the same hole the SVS used. It takes a Groco 1 1/4 - 1 1/2 thru hull scoop.

Happy to answer any questions. No more air! Thanks to everyone!

Sorry about the rotation, it should straighten out when you click the pic.

Attachments

Glad you got it resolved, congratulations.

The "seacock" looks like a thru-hull fitting with an inline ball valve on top. Strictly speaking that's not a seacock by ABYC standards, as the threads are almost certainly incompatible (unless the thru-hull uses combination threads, it doesn't look long enough to be that style), NPT vs. NPS, and because it lacks an integral flange it is unlikely to pass the 500 lb. 30 second static load test. Did the yard supply the parts?

More here https://stevedmarineconsulting.com/seacock-selection-service-and-avoiding-the-pitfalls-2/

The "seacock" looks like a thru-hull fitting with an inline ball valve on top. Strictly speaking that's not a seacock by ABYC standards, as the threads are almost certainly incompatible (unless the thru-hull uses combination threads, it doesn't look long enough to be that style), NPT vs. NPS, and because it lacks an integral flange it is unlikely to pass the 500 lb. 30 second static load test. Did the yard supply the parts?

More here https://stevedmarineconsulting.com/seacock-selection-service-and-avoiding-the-pitfalls-2/

Glad you got it resolved, congratulations.

The "seacock" looks like a thru-hull fitting with an inline ball valve on top. Strictly speaking that's not a seacock by ABYC standards, as the threads are almost certainly incompatible (unless the thru-hull uses combination threads, it doesn't look long enough to be that style), NPT vs. NPS, and because it lacks an integral flange it is unlikely to pass the 500 lb. 30 second static load test. Did the yard supply the parts?

More here https://stevedmarineconsulting.com/seacock-selection-service-and-avoiding-the-pitfalls-2/

Yes they did. They are both Groco parts. Are they incompatible? I know the thru hull is a Groco 1 1/4 - 1 1/2 scoop strainer. The valve is Groco too I believe but not sure which model. They did put a wood backing block between the two. What can I check to make sure it was done right?

Glad you got it resolved, congratulations.

The "seacock" looks like a thru-hull fitting with an inline ball valve on top. Strictly speaking that's not a seacock by ABYC standards, as the threads are almost certainly incompatible (unless the thru-hull uses combination threads, it doesn't look long enough to be that style), NPT vs. NPS, and because it lacks an integral flange it is unlikely to pass the 500 lb. 30 second static load test. Did the yard supply the parts?

More here https://stevedmarineconsulting.com/seacock-selection-service-and-avoiding-the-pitfalls-2/

Oh Crap!!!! I looked them up and you're right. The thru hull is NPS and the valve is NPT. The nightmare continues! What are my remedies? Can an adapter be fitted now that the NPT threads have munched the NPS threads? Are yards required to follow ABYC standards? Wil my insurance be void? I am freakin out here!!!

Similar threads

- Replies

- 3

- Views

- 557

- Replies

- 53

- Views

- 5K