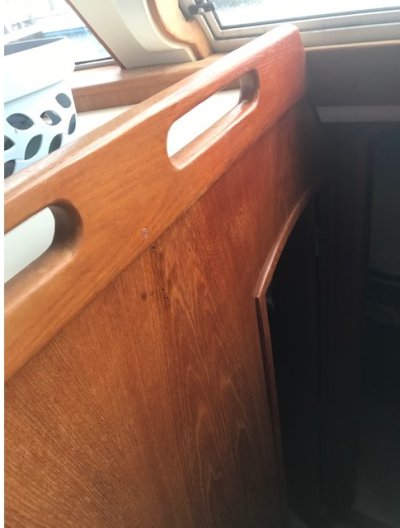

The MS390 has lots of interior teak wood. The one we picked up this July had lots of sun damage [windows and companionway] and galley area heat damage to the interior wood. Clearly two previous owners were intimidated to doing anything about it and just "let it go". (Original finish visibly flaking off! Damn shame.) First attempt: Sand paper + Watco Teak Oil. No good. (It took to the bare wood too differently compared to the places where original finish was still intact, and the transition between the two was even worse!)

Second attempt: Sanded all the Watco down, and sanded so there would be a more distinct line between bare wood and original finish (no "transition" with partial original finish and bare wood). Then experimented with Minwax Wood Finish Penetrating Stain "Gunstock 231". That worked great for the large forward facing windows and the companionway going down below forward. I did a generous overlap of several inches over the original finish as well as on the newly exposed bare wood. It matched up perfectly, and end result is mere mortals would not be able to tell the old from the new. Recommend a second coat or three with Minwax fast-drying Polyurethane "Clear Satin" in the badly sundamaged areas. Declared success.

To left of the galley/stove area, tried the same procedure with the same products. The "Gunstock 231" came out a little bit darker than I'd like in comparison to the original surrounding wood. So, if proactively looking for it, mere mortals could see there is a slightly darker refinished area and lighter area surrounding. Perhaps I should have ONLY used the Minwax fast-drying polyurethane "Clear Satin" in that area (several coats)?

Too late now! But frankly, very much good enough for a 2000 Mainship 390, 20-year old boat. Looking much better inside now.

My advice: "Can't be scared!" Go for it. Not a scary project for this non-pro.

(I wish I had before and after pics... small 4" electric sander w/velcro pads and vacuum saved the day.)

By the way, the Watco Teak Oil did a VERY nice job throughout the rest of the salon's teak wood where there was no sun damage. It really polished things up nice. So, we'll do that again every season... VERY light coat with lint free rag (carefully dispose of rags... risk of spontaneous combustion.)

I am not affiliated with any of the products named here! I just know how helpful it can be to have those details! Good luck.

Fortunately, the previous owners did a great job of taking care of everything else besides the interior wood.

) but rather a very thin coating. I will be interested in Larry's and others adventures in this regard, but the very last thing I want to mess with on my particular boat is its interior wood finish. If it ever got really bad, I'd be breaking out the Grand Banks beige Awlgrip.

) but rather a very thin coating. I will be interested in Larry's and others adventures in this regard, but the very last thing I want to mess with on my particular boat is its interior wood finish. If it ever got really bad, I'd be breaking out the Grand Banks beige Awlgrip.