jimisbell

Guru

- Joined

- Jan 13, 2018

- Messages

- 643

- Location

- USA

- Vessel Name

- Papillon

- Vessel Make

- 1978 Mainship 34 Trawler #95

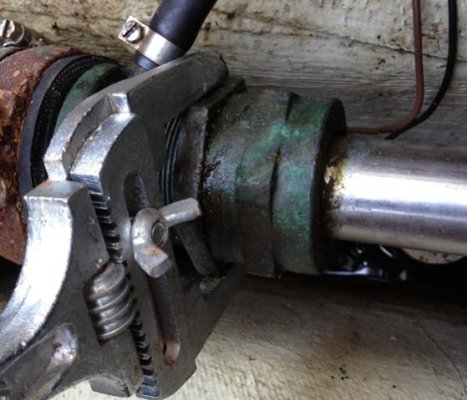

I'll go inform every millwright and industrial mechanic I've ever worked with that they are doing it wrong.

But you have a point. If you are not comfortable with doing this, then don't.

Yes, that really wasnt what I was talking about. I work on lathes and you couldnt get anything done without it spinning....LOL