Waterant

Senior Member

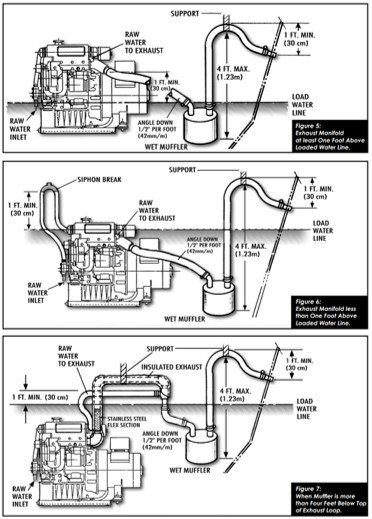

Was this exhaust system designed by morons or my simple mind is missing something?

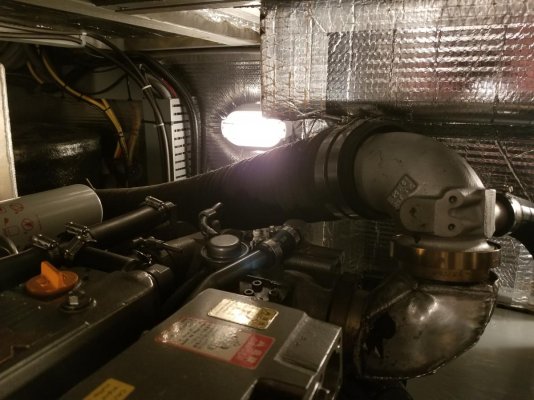

while disassembling the port engine, which was damaged by water that got inside i noticed the muffler is full of water up to the entry pipe (see the image)

any small wave action and a lot of water will go into the turbo and the engine.

how is it possible for Mainship to build hundreds of boats with the exhaust system designed this way? how many engines got damaged because of this?

Or I'm missing something and on Mainships the water does not flow down inside the 6" pipe for some magical reason?

has anyone modified the exhaust system specifically on Mainship 430 with Yanmars 6LYA engines? is there any after-market solution or the custom-designed and made raised elbows is my only option to fix that?

while disassembling the port engine, which was damaged by water that got inside i noticed the muffler is full of water up to the entry pipe (see the image)

any small wave action and a lot of water will go into the turbo and the engine.

how is it possible for Mainship to build hundreds of boats with the exhaust system designed this way? how many engines got damaged because of this?

Or I'm missing something and on Mainships the water does not flow down inside the 6" pipe for some magical reason?

has anyone modified the exhaust system specifically on Mainship 430 with Yanmars 6LYA engines? is there any after-market solution or the custom-designed and made raised elbows is my only option to fix that?