Dougcole

Guru

Hi All,

When I mentioned in a recent post that I was going to try to repair the holding tank sender/sensor on my Mainship 400 a few people asked me to let them know how to do it and to post pics if possible.

I finished this job tonight, so here goes.

Start by pumping and flushing your holding tank.

1. Locate the sender, which is on top of the holding tank, just forward of where the floor ends under the companionway steps. I carefully measured and marked the center of the sender on the floor with a sharpie so I would know where to cut.

2. This is the hardest part. Use a 4" hols saw to cut through the floor right above the sender. I reccomend investing in a hole saw if you don't have one, don't try to do it with a jigsaw as there is not enough clearance for the blade. Also, hole saws just make a cleaner hole. If you own a MS 400 you will likely use it again (like, in order to access the fuel tanks sender on the stb side) so don't cheap out.

No one likes cutting a big hole in their boat, even if it is in an interior deck, but there is no way around it. You can't get the sender out without cutting a hole.

There are two layers of 1/2" plywood you will have to cut through. It takes a while and makes some dust.

3. Clip the two wires, orange and yellow, leading to the sender.

4. Unscrew the sender from the tank. Mine was a little tough to get out as it had some sealant on the threads. I was careful and used a pipe wrench. The threaded plastic fitting screws out, not the metal part.

5. Pull the sender out through the hole you cut. Put a rag or something in the tank opening to reduce odor.

6. OK, here is the nasty part. My sender was covered in about 1/2 inch of a hard black scale. In the spirit of politeness and decorum I did not take a pic of it. Trust me, it was gross.

I dropped the entire assembly in 1/2 gallon of barnacle buster and let it bubble for 1/2 hour then scraped it with a flat head screwdriver and hosed it off every few minutes. When I had the outside clean I soaked it again, then hosed some more. Eventually I was able to remove the retaining clip at the bottom of the tube and then slide the tube off. It wasn't easy to get the tube off, it had scale/sludge inside it, which is what was keeping the float from moving.

After I got the tube off I scraped the inside and the float, then hosed some more. Eventually, it came clean and I reassembled it.

7. Screw the sender back into the tank and reconnect the wires. I used quick connectors rather than butt connectors to make it easier next time.

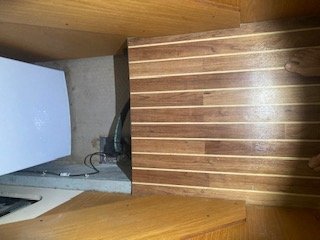

8. Install a pie plate fitting in the hole in the floor. I didn't bother to caulk it as it is in a dry spot. When the steps are closed the pie plate is hidden.

I put about ten gallons of water into my holding tank to check the gauge. It is working perfectly.

It's an unpleasant job but not a difficult one. Hope this helps. Pics below.

When I mentioned in a recent post that I was going to try to repair the holding tank sender/sensor on my Mainship 400 a few people asked me to let them know how to do it and to post pics if possible.

I finished this job tonight, so here goes.

Start by pumping and flushing your holding tank.

1. Locate the sender, which is on top of the holding tank, just forward of where the floor ends under the companionway steps. I carefully measured and marked the center of the sender on the floor with a sharpie so I would know where to cut.

2. This is the hardest part. Use a 4" hols saw to cut through the floor right above the sender. I reccomend investing in a hole saw if you don't have one, don't try to do it with a jigsaw as there is not enough clearance for the blade. Also, hole saws just make a cleaner hole. If you own a MS 400 you will likely use it again (like, in order to access the fuel tanks sender on the stb side) so don't cheap out.

No one likes cutting a big hole in their boat, even if it is in an interior deck, but there is no way around it. You can't get the sender out without cutting a hole.

There are two layers of 1/2" plywood you will have to cut through. It takes a while and makes some dust.

3. Clip the two wires, orange and yellow, leading to the sender.

4. Unscrew the sender from the tank. Mine was a little tough to get out as it had some sealant on the threads. I was careful and used a pipe wrench. The threaded plastic fitting screws out, not the metal part.

5. Pull the sender out through the hole you cut. Put a rag or something in the tank opening to reduce odor.

6. OK, here is the nasty part. My sender was covered in about 1/2 inch of a hard black scale. In the spirit of politeness and decorum I did not take a pic of it. Trust me, it was gross.

I dropped the entire assembly in 1/2 gallon of barnacle buster and let it bubble for 1/2 hour then scraped it with a flat head screwdriver and hosed it off every few minutes. When I had the outside clean I soaked it again, then hosed some more. Eventually I was able to remove the retaining clip at the bottom of the tube and then slide the tube off. It wasn't easy to get the tube off, it had scale/sludge inside it, which is what was keeping the float from moving.

After I got the tube off I scraped the inside and the float, then hosed some more. Eventually, it came clean and I reassembled it.

7. Screw the sender back into the tank and reconnect the wires. I used quick connectors rather than butt connectors to make it easier next time.

8. Install a pie plate fitting in the hole in the floor. I didn't bother to caulk it as it is in a dry spot. When the steps are closed the pie plate is hidden.

I put about ten gallons of water into my holding tank to check the gauge. It is working perfectly.

It's an unpleasant job but not a difficult one. Hope this helps. Pics below.