Dougcole

Guru

Hi All,

Like many 2005 and later 400s, the corrosion under the powder coating on our cockpit doors had become a big issue, they looked really bad. So last week I jumped into the pretty big project of refinishing them. I had a lot of good advice from nautical and industrial supplies in Stuart, FL.

By the way, I wore a rebreather for all of this process. SOme of the chemicals have bad reps.

Step one, I pulled out all of the stainless screws, which are a big part of the corrosion problem due to dissimilar metals.

Step two, sanding. I started with a wire brush on a drill. As I do other parts of the boat I'm going to use a flap disk on my grinder, but the brush worked ok. Followed that with 60 grit paper on my oscillating tool, then with 100 grit on my 5" random orbital sander. I was told to leave on any of the coating that didn't come off with this sanding method, as it was adhered better than anything I could apply after.

Step three, acid wash. I was told that it is important to do the next two steps as soon as you finish sanding, so that is what I did. I painted on the acid wash with a disposable brush, then washed it off with water, as per the instructions.

Step four, Aluma Prep. Similar to the acid wash, paint on then wash off with water.

Step five, two coats of two part epoxy primer. I used a better disposable brush called a urethaner. No sanding in between. Let dry overnight after second coat.

Step six, light sanding with 120 grit.

Step seven, Awl Grip, two part, eggshell white, three coats. Medium sanding with 120 grit in between. I let each coat dry 10 to 12 hours and used a good quality synthetic brush.

Step eight, reinstall screws bedded in Teff Gel.

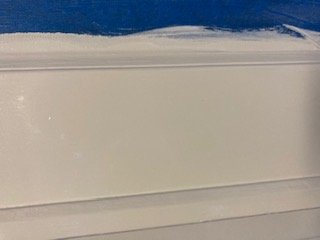

I'm pleased with the results, pics below show before and after. I hope it lasts.

Like many 2005 and later 400s, the corrosion under the powder coating on our cockpit doors had become a big issue, they looked really bad. So last week I jumped into the pretty big project of refinishing them. I had a lot of good advice from nautical and industrial supplies in Stuart, FL.

By the way, I wore a rebreather for all of this process. SOme of the chemicals have bad reps.

Step one, I pulled out all of the stainless screws, which are a big part of the corrosion problem due to dissimilar metals.

Step two, sanding. I started with a wire brush on a drill. As I do other parts of the boat I'm going to use a flap disk on my grinder, but the brush worked ok. Followed that with 60 grit paper on my oscillating tool, then with 100 grit on my 5" random orbital sander. I was told to leave on any of the coating that didn't come off with this sanding method, as it was adhered better than anything I could apply after.

Step three, acid wash. I was told that it is important to do the next two steps as soon as you finish sanding, so that is what I did. I painted on the acid wash with a disposable brush, then washed it off with water, as per the instructions.

Step four, Aluma Prep. Similar to the acid wash, paint on then wash off with water.

Step five, two coats of two part epoxy primer. I used a better disposable brush called a urethaner. No sanding in between. Let dry overnight after second coat.

Step six, light sanding with 120 grit.

Step seven, Awl Grip, two part, eggshell white, three coats. Medium sanding with 120 grit in between. I let each coat dry 10 to 12 hours and used a good quality synthetic brush.

Step eight, reinstall screws bedded in Teff Gel.

I'm pleased with the results, pics below show before and after. I hope it lasts.

Attachments

Last edited: