Mermaid

Senior Member

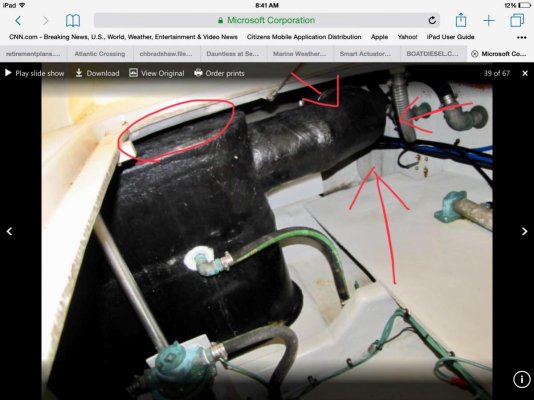

I have a 2005 Mainship 400 Trawler and I want to replace the exhaust hoses as a preventative measure given their age. The one that baffles me is the large hose that leaves the muffler and goes out of the boat at the waterline on the starboard side near the stern. The boat is in the yard a couple of hours away from me, so I had to borrow KapnKarl’s photo and mark it up. See the arrows I drew on the photo - it’s that hose that is troubling me.

Has anyone tackled this job? Even the yard guys are scratching their heads, and if some has done it, perhaps I can pass along a few tips.

There is no room to remove the muffler - look at the spot I circled - no room to tip it. We think it was dropped in during construction before the deck and house was dropped on. I really don’t want to cut the cockpit deck to get at this.

Is it possible to unscrew the muffler from the floor, assuming there aren’t screws on the inaccessible side, and then slide it forward to to get the hose off?

Has anyone tackled this job? Even the yard guys are scratching their heads, and if some has done it, perhaps I can pass along a few tips.

There is no room to remove the muffler - look at the spot I circled - no room to tip it. We think it was dropped in during construction before the deck and house was dropped on. I really don’t want to cut the cockpit deck to get at this.

Is it possible to unscrew the muffler from the floor, assuming there aren’t screws on the inaccessible side, and then slide it forward to to get the hose off?

Attachments

Last edited: