You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cummins 6BT5.9 water pump cam bolt sheared off

- Thread starter fryedaze

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Greg S

Senior Member

I have had this happen several times on one of my trucks. In my case it threads into a blind hole on a bracket. It is fine thread so has to be a grade five or grade eight. Grade eight is much easier to find than a fine thread grade five. After way too many broken bolts I found that a grade eight bolt will easily fracture IF NOT TORQUED TO SPEC.

Eleven years ago I torqued it to spec and haven’t had one break since.

How many broke? On one cross country trip of about five thousand miles I think it was four broken alternator pivot bolts.

Eleven years ago I torqued it to spec and haven’t had one break since.

How many broke? On one cross country trip of about five thousand miles I think it was four broken alternator pivot bolts.

twistedtree

Guru

I have had this happen several times on one of my trucks. In my case it threads into a blind hole on a bracket. It is fine thread so has to be a grade five or grade eight. Grade eight is much easier to find than a fine thread grade five. After way too many broken bolts I found that a grade eight bolt will easily fracture IF NOT TORQUED TO SPEC.

Eleven years ago I torqued it to spec and haven’t had one break since.

How many broke? On one cross country trip of about five thousand miles I think it was four broken alternator pivot bolts.

I assume they were over torqued when they broke?

firehoser75

Guru

- Joined

- Feb 18, 2018

- Messages

- 1,705

- Location

- Canada

- Vessel Name

- former owner of "Pilitak"

- Vessel Make

- Nordic Tug 37

If this is the "stock" Sherwood brand pump, I recommend changing it out for a new SMX 1730 pump from Seaboard Marine (sbmar.com). It is a far superior pump in almost everyway, and does not cost much if any more. It is a "plug and play" or direct fit. It comes with an impeller puller as well, making impeller changes easier.

There is info about the reasons why this is a better pump under "Tony's Tips" on this site (sbmar.com).

I am not affiliated in any way with this company (or any staff), just a happy customer.

There is info about the reasons why this is a better pump under "Tony's Tips" on this site (sbmar.com).

I am not affiliated in any way with this company (or any staff), just a happy customer.

dvarholy

Veteran Member

Never had this issue on either of mine. If the cam bolt is too long, it could be trimmed down or shimmed with washers. Have had no issues with the original Sherwood raw water pumps with well over 2,000 hours on each.

Daniel

Daniel

Greg S

Senior Member

I assume they were over torqued when they broke?

Under torqued. Just snug with a wrench.

To get the strength rated, the bolt has to be tightened to the torque value, less will allow it to break.

Greg S

Senior Member

Under torqued. Just snug with a wrench.

To get the strength rated, the bolt has to be tightened to the torque value, less will allow it to break.

Seeing the photos, my application is totally different. I pictured something else.

CompuNerd

Veteran Member

- Joined

- Nov 16, 2020

- Messages

- 57

- Vessel Name

- Double Haven

- Vessel Make

- 40' Pacific Trawler

If this is the "stock" Sherwood brand pump, I recommend changing it out for a new SMX 1730 pump from Seaboard Marine (sbmar.com). It is a far superior pump in almost everyway, and does not cost much if any more. It is a "plug and play" or direct fit. It comes with an impeller puller as well, making impeller changes easier.

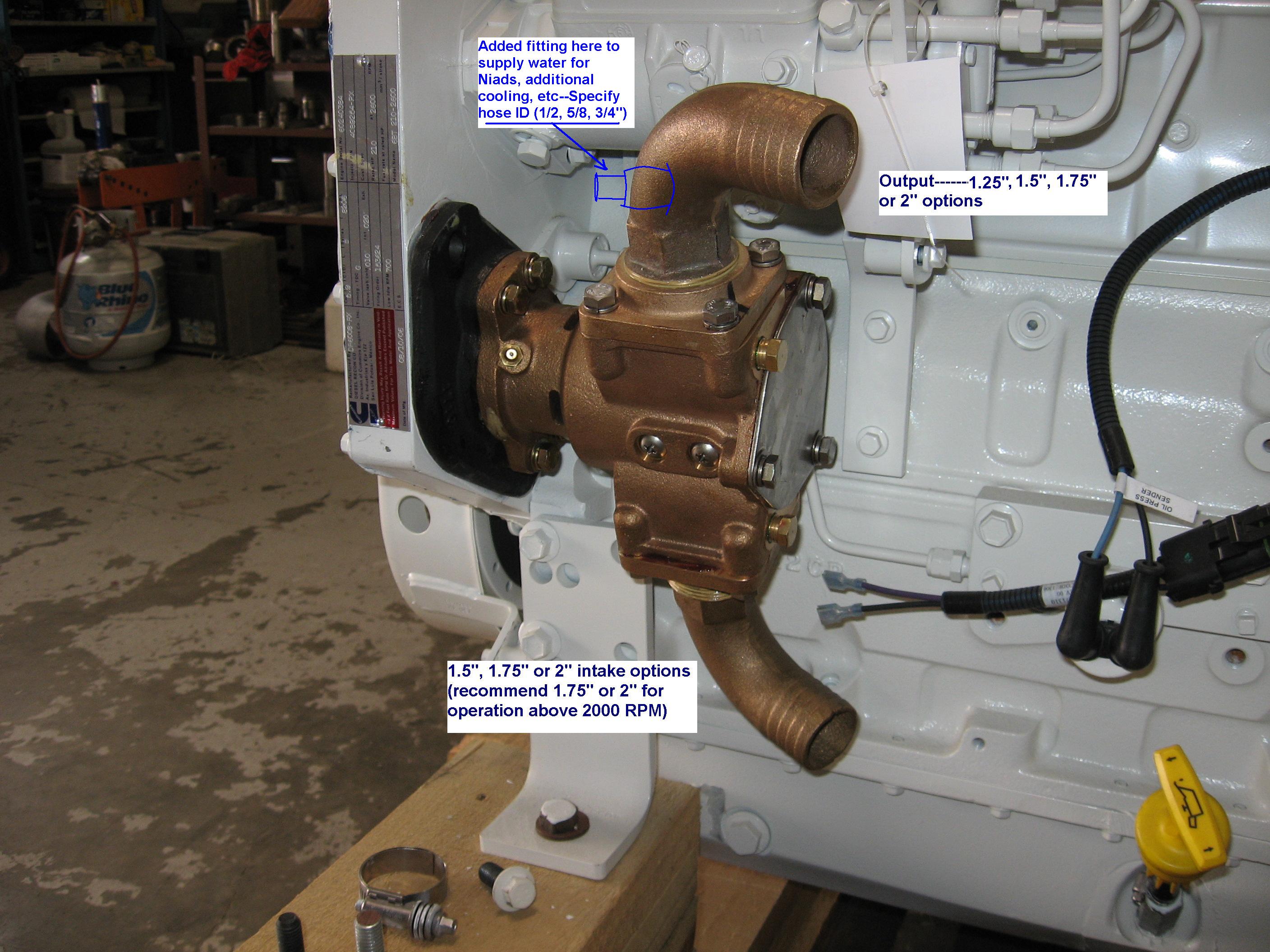

EXCEPT it's not quite plug-and-play for some 6BT 5.9 M engines. Mine's a 2002 and turns out the SMX has a notably higher flow rate than the original Sherwood. This means it's not appropriate for the 1.25" circuit without some modification for the inflow and output circuits. Yes, I know they have the photos of it mounted on a 6BT (see image). But it's also not retrofitted to a 1.25" circuit. Drop an email to the customer support folks at Seaboard and see if the SMX will work with your setup.

I had to go with another Sherwood for that reason. The retrofit cost would have been too much for the benefit gained. I'd be better off doing a repower. And if anyone knows who at Sherwood designed their back-assward water pump, let me know, would you? I'd like to have a word with them.

Drop an email to the customer support folks at Seaboard and see if the SMX will work with your setup.

kapnd

Guru

- Joined

- Aug 31, 2013

- Messages

- 880

- Location

- usa

- Vessel Name

- #31

- Vessel Make

- ex-Navy MUB 50 fish/cruise

The SMX pump will work on your motor, and does indeed supply a lot more water than the OEM Sherwood.

Being a flexible vane pump, it’s output can be restricted without damaging the pump, but do be sure all hoses and clamps downstream are in top shape, as they will be operating under more pressure.

Don’t be shy about tapping raw water for other uses too.

I have seen impellor modified by cutting off every other vane to reduce output.

Being a flexible vane pump, it’s output can be restricted without damaging the pump, but do be sure all hoses and clamps downstream are in top shape, as they will be operating under more pressure.

Don’t be shy about tapping raw water for other uses too.

I have seen impellor modified by cutting off every other vane to reduce output.

BeeJay

Senior Member

The new cam that broke the bolts allows the bolt to pass through. The old one bottoms out.

When the bolt is bottomed out in the old cam it doesn't move laterally. The new one move side to side a small amount. It may be vibrating and break

View attachment 131192View attachment 131193

If the cam moves it will break the bolt. The old cam looks ok is there any reason not to re-use it ? Unless it is overly thin I would suggest using the old cam. The bolt should only retain the cam and not be under any additional load, if the new cam is moving you have a problem and the bolt will fatigue.

fryedaze

Guru

- Joined

- Sep 4, 2011

- Messages

- 1,722

- Location

- USA

- Vessel Name

- Fryedaze

- Vessel Make

- MC 42 (Overseas Co) Monk 42

We did re-use the old cam.If the cam moves it will break the bolt. The old cam looks ok is there any reason not to re-use it ? Unless it is overly thin I would suggest using the old cam. The bolt should only retain the cam and not be under any additional load, if the new cam is moving you have a problem and the bolt will fatigue.

fryedaze

Guru

- Joined

- Sep 4, 2011

- Messages

- 1,722

- Location

- USA

- Vessel Name

- Fryedaze

- Vessel Make

- MC 42 (Overseas Co) Monk 42

WELL IT HAPPENDED AGAIN!!!

We are going to change the pump with a Seaboard. We need to jack the port mount up. Where do we place the hydraulic bottle pump and how do we support it. I havent look at his boat yet, just sbmar Tony Tips review. Need a little help

We are going to change the pump with a Seaboard. We need to jack the port mount up. Where do we place the hydraulic bottle pump and how do we support it. I havent look at his boat yet, just sbmar Tony Tips review. Need a little help

kapnd

Guru

- Joined

- Aug 31, 2013

- Messages

- 880

- Location

- usa

- Vessel Name

- #31

- Vessel Make

- ex-Navy MUB 50 fish/cruise

WELL IT HAPPENDED AGAIN!!!

We are going to change the pump with a Seaboard. We need to jack the port mount up. Where do we place the hydraulic bottle pump and how do we support it. I havent look at his boat yet, just sbmar Tony Tips review. Need a little help

Many installations don’t allow room to get under the motor with a jack, so you may have to get ingenious with some kind of lifting lever instead.

Putting a jack against the hull is dangerous, use adequate blocking to prevent pinpoint loading, or use a sandbag against the hull.

Be careful not to mess up the height of the mounts, or you’ll wind up doing alignment too.

fryedaze

Guru

- Joined

- Sep 4, 2011

- Messages

- 1,722

- Location

- USA

- Vessel Name

- Fryedaze

- Vessel Make

- MC 42 (Overseas Co) Monk 42

Thanks for all the help. It appears that the hole in the casing was slightly oblong. We think that may have allowed the cam retainer bolt to vibrate and eventually fracture. The bolt is small. We got a high strength socket head machine bolt in a larger size. Drilled the casing hole and tapped the new cam. Two new seaboard pumps are on their way to our next marina stop. It really sucks that the engine mount bracket has to be removed to replace the pumps. The plan is to keep the new pumps in standby until needed. Thanks again.