ok bluewater owners, here's another question.

i'm doing some cleanup on the ac systems wiring on my boat and i'm wondering where the original ac neutral buss is located.

i see some of what appears to be factory terminal strips under the helm station but the wire colors aren't right. i see some of the terminals jumped together, and there's also what appears to be a green bonding wire on some of them. i can see nice bundles from the ac breakers that seem to go down into the wireway that leads to the engine room, but nothing appears to land on a neutral buss with any white colors. i'm thinking the factory may not have used white for the neutral.

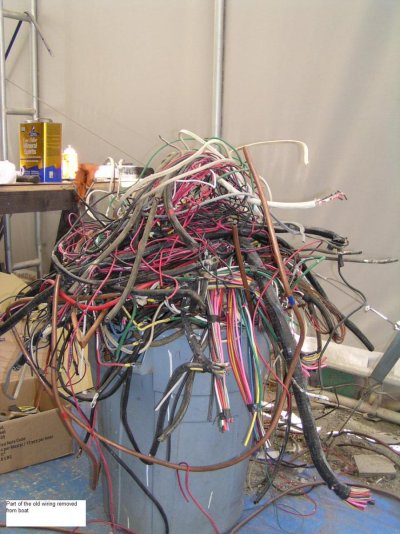

the previous owner did a bunch of wiring and for some reason he made his runs extra long and just rolled up all the excess and left it in a pile under the helm making it even more difficult to trace things out. i will be cleaning that up as well. there must be 50 pounds of boat cable rolled up in there along with a rolled up bunch of 4/0 that comes from the dc busses down below. just crazy.

i've dealt with the "leave it long in case you have to shorten it later" mentality, but this is extreme.

can anyone shed some light on this for me?

i'm doing some cleanup on the ac systems wiring on my boat and i'm wondering where the original ac neutral buss is located.

i see some of what appears to be factory terminal strips under the helm station but the wire colors aren't right. i see some of the terminals jumped together, and there's also what appears to be a green bonding wire on some of them. i can see nice bundles from the ac breakers that seem to go down into the wireway that leads to the engine room, but nothing appears to land on a neutral buss with any white colors. i'm thinking the factory may not have used white for the neutral.

the previous owner did a bunch of wiring and for some reason he made his runs extra long and just rolled up all the excess and left it in a pile under the helm making it even more difficult to trace things out. i will be cleaning that up as well. there must be 50 pounds of boat cable rolled up in there along with a rolled up bunch of 4/0 that comes from the dc busses down below. just crazy.

i've dealt with the "leave it long in case you have to shorten it later" mentality, but this is extreme.

can anyone shed some light on this for me?