Alaskan Sea-Duction

Guru

- Joined

- Jul 6, 2012

- Messages

- 8,058

- Location

- USA

- Vessel Name

- Alaskan Sea-Duction

- Vessel Make

- 1988 M/Y Camargue YachtFisher

So this has happened to me twice now. Sea Conditions were following Seas or off the Port Stern.

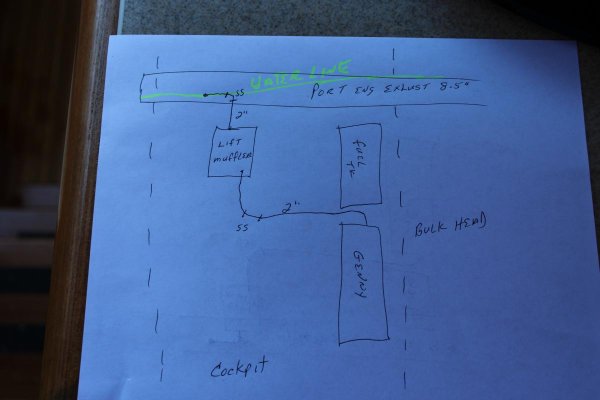

Setup:

Genny in cockpit.

Exhaust line is below waterline then enters lift muffler. Top of lift muffler just below water line.

Genny exhaust designed to empty into Port Engine Exhaust.

See schematic.

Solutions:

1. Flapper on main engine exhaust. Problem exhaust tube is 8.5 inches.

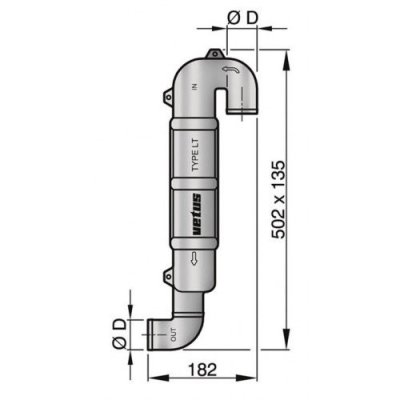

2. Install a check valve on top of lift muffler. Exhaust is 2 inches.

3. Install a loop in the exhaust line. Can genny handle this?

I have no way of knowing if this is the original design. When we bought the boat in 03, the generator had new exhaust lines.

I am heading over to Shearwater Marine and see what they come up with, but as always I put forth this issue to my TF brothers.

What say you?

Setup:

Genny in cockpit.

Exhaust line is below waterline then enters lift muffler. Top of lift muffler just below water line.

Genny exhaust designed to empty into Port Engine Exhaust.

See schematic.

Solutions:

1. Flapper on main engine exhaust. Problem exhaust tube is 8.5 inches.

2. Install a check valve on top of lift muffler. Exhaust is 2 inches.

3. Install a loop in the exhaust line. Can genny handle this?

I have no way of knowing if this is the original design. When we bought the boat in 03, the generator had new exhaust lines.

I am heading over to Shearwater Marine and see what they come up with, but as always I put forth this issue to my TF brothers.

What say you?