Djoub

Veteran Member

Still new to me, 98 Mainship Trawler with single 370 Yanmar, 2 157 gallon tanks. A couple of months ago my engine stopped leaving me stranded. Thought it was clogged fuel filters so I learned how to change them and bleed the system. A couple of weeks ago, went to start engine and it would not start, just turn over. Problem was eventually traced to air entering fuel lines and showing up in Racor bowl and eventually to FI. I have (or had) a home grown version of a fuel polisher and instead of tracking down the air leak I decided to remove and replace everything from the fuel tank valves to the input to Racor and also rebuild the Racor.

I’m still getting air bubbles in the Racor, even with a 3’ hose straight from the Racor to the valve on top of tank. If I close the supply valve, bubbles stop.

All background to my real question:

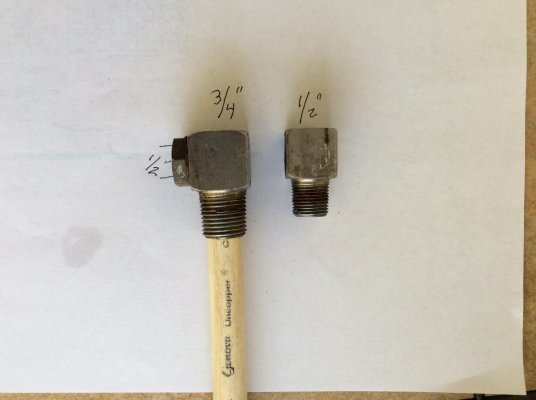

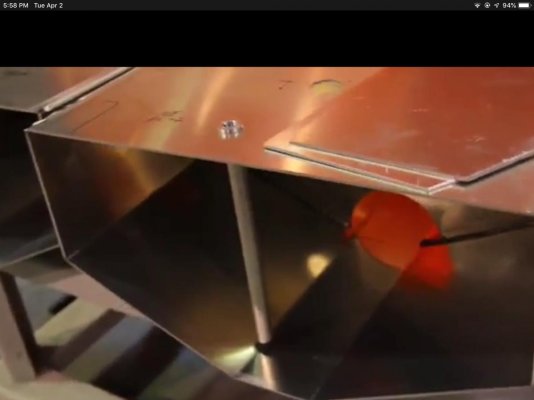

What kind of fitting is on these tanks? I expected to see a pick up tube on the end of the tank fittings. Looks like a tube down a half inch or so in the tank side that I can’t lift out or push down. Is it a friction fit when you tighten the fitting on to the tank and it pushes down to the tube? Went to WM but they didn’t know. Also I have read the I need a anti siphon valve since my engine is below my tanks.

Help, I’m tied of of smelling diesel fuel.

I’m still getting air bubbles in the Racor, even with a 3’ hose straight from the Racor to the valve on top of tank. If I close the supply valve, bubbles stop.

All background to my real question:

What kind of fitting is on these tanks? I expected to see a pick up tube on the end of the tank fittings. Looks like a tube down a half inch or so in the tank side that I can’t lift out or push down. Is it a friction fit when you tighten the fitting on to the tank and it pushes down to the tube? Went to WM but they didn’t know. Also I have read the I need a anti siphon valve since my engine is below my tanks.

Help, I’m tied of of smelling diesel fuel.