Choices

Guru

- Joined

- Apr 16, 2018

- Messages

- 898

- Location

- Montgomery, Tx

- Vessel Name

- Choices

- Vessel Make

- 36 Grand Banks Europa

My boat does not have a fuel polishing set up, and burns fuel so slow I would like to add one.

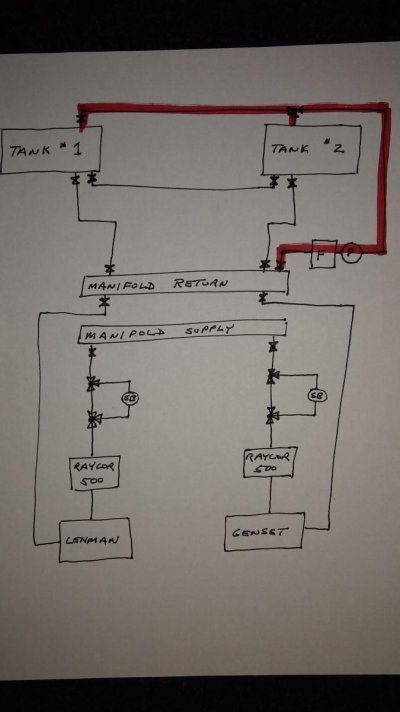

Below is my layout in black. Red is what I would like to add for the polisher.

My plan is to use a Walbro 12v pump plumbed after a Raycor 500 with a vacuum gauge, that will keep spare parts easy.

There is a threaded port in the manifold, so I can nipple off of that and mount everything to the back of the manifold structure.

Each tank has a threaded tap at the top of the tank that is nipple blocked, that will be my return. I will always return fuel to the same isolated tank.

I think I can control where it goes and isolate each tank this way.

See any problems?

Below is my layout in black. Red is what I would like to add for the polisher.

My plan is to use a Walbro 12v pump plumbed after a Raycor 500 with a vacuum gauge, that will keep spare parts easy.

There is a threaded port in the manifold, so I can nipple off of that and mount everything to the back of the manifold structure.

Each tank has a threaded tap at the top of the tank that is nipple blocked, that will be my return. I will always return fuel to the same isolated tank.

I think I can control where it goes and isolate each tank this way.

See any problems?