Well, I’ve been cleaning and getting ready for another great year of boating, I have been considering adding another bilge pump, I have one now, it’s a great pump and has never let me down. How many pumps does a 65’ Boat need, two/three? There were two engine driven pumps but they are inoperable, I had a 110v pump but I found out it was junk during my bilge cleaning fun. Well let the bullets fly

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How many bilge pumps

- Thread starter swampu

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Lou_tribal

Guru

How many through hull ? I would ensure the number/capacity of the pump can cope with water ingress from these in case of need.

L

L

MurrayM

Guru

Our boat came with one bilge pump located just above the stuffing box. All through hulls located in engine room. Limber hole through bulkhead is smaller diameter than through hulls. What were they thinking?

*Note to self* Install bilge pump of a size capable to keep up with broken through hull in engine room this year!

*Note to self* Install bilge pump of a size capable to keep up with broken through hull in engine room this year!

Tom.B

Moderator Emeritus

- Joined

- Jul 30, 2009

- Messages

- 5,839

- Location

- USA

- Vessel Name

- Skinny Dippin'

- Vessel Make

- Navigator 4200 Classic

Our boat came with one bilge pump located just above the stuffing box. All through hulls located in engine room. Limber hole through bulkhead is smaller diameter than through hulls. What were they thinking?

*Note to self* Install bilge pump of a size capable to keep up with broken through hull in engine room this year!

Same here. Our 42’ has two (what I would call small) Rule 2000s. Neither are place where the water collects and I worry able the true capacity and the ability for them to keep up should we clobber something with our props. I totally have the same note-to-self you do.

I plan to replace one with the small Whale IC that has the remote pickup to get to where the bow water puddles, then replace the one in the rudder area with a slightly larger one (the largest I can get that pumps thru a 1” tube). Finally add a new and much larger one between the motors that can really pump out quickly. That will a new thru hull and some decision making though.

Anyway, to the OP. The answer is that, within reason, you can never have too much. But don’t expect the factory setup to be sufficient. Always upgrade if you can. The advice from others is good. Find one that makes you feel good that it is there.

In an emergency, I would not rely on a 110V pump or an engine driven pump to keep my boat from sinking. They can be helpful, but DC is a more reliable power source.

There are really two services for bilge pumps: 1) To pump out minor leakages like from a prop shaft gland. 2) In an emergency pump out water as fast as it comes in or a least give you more time to find the source of the water and fix it.

The first type is often smallish, about 500 gph. The second type needs to be DC powered and big- 2,000 gph at least, maybe more for your 65' boat. This willl probably need dedicated DC circuit as it will draw 10-20 amps and big discharge hose. It's float switch should be mounted an inch or two higher than the smaller pump's.

David

There are really two services for bilge pumps: 1) To pump out minor leakages like from a prop shaft gland. 2) In an emergency pump out water as fast as it comes in or a least give you more time to find the source of the water and fix it.

The first type is often smallish, about 500 gph. The second type needs to be DC powered and big- 2,000 gph at least, maybe more for your 65' boat. This willl probably need dedicated DC circuit as it will draw 10-20 amps and big discharge hose. It's float switch should be mounted an inch or two higher than the smaller pump's.

David

David Rive

Senior Member

Our 34' tug has three. Each is 2000 gph.

David

David

Xsbank

Guru

- Joined

- Sep 7, 2013

- Messages

- 3,791

- Location

- Canada

- Vessel Name

- Gwaii Haanas

- Vessel Make

- Custom Aluminum 52

Don’t forget that all these pumps lose significant performance when pumping uphill. I forget the numbers but a 2000 will only pump 2000 if the voltage is perfect, the outlet is horizontal and the intake is perfectly clear. Also, Seaflo are significantly cheaper than Rule so you can buy lots of them and wire them everywhere water might collect.

Consider also your strategy. If you find it difficult to move in your bilge or are not too handy, consider the bilge pump a delaying tactic (like fire extinguishers on fibreglass boats) to give to adequate time to abandon ship safely.

Consider also your strategy. If you find it difficult to move in your bilge or are not too handy, consider the bilge pump a delaying tactic (like fire extinguishers on fibreglass boats) to give to adequate time to abandon ship safely.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,288

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Looking at the charts which only go up to 40 to 45’ boats, which recommend 2000 to 4000 gph, I would be looking in the 6000 gph area. Make sure that they have wire for a 3% voltage drop and smooth bore discharge hose.

Lou_tribal

Guru

Personally to have experienced the usefulness of them I will say that you will never have enough and having more than enough cannot be bad thing

L

L

Our 42 foot boat has four 1500-2000 gph bilge pumps. As far as I know, this was the factory set up. All factory wired with switches and fuses outside of the 12v main buss.

We also have a 120 v portable crash pump.

We also have a 120 v portable crash pump.

Last edited:

Lou_tribal

Guru

And what about staged pump like a 800g/h then higher a bigger one and then a bigger one etc or is the opposite better? Or is all staged same better? Or I am just out of my mind

L

L

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,288

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Generally the smaller pump goes lower as it can pump out to a lower level than a larger pump can. Mount the larger pump a bit higher so if the small pump can’t keep up the larger pump will come online and hopefully take care of it.

Simi 60

Guru

- Joined

- Jul 1, 2016

- Messages

- 5,482

- Location

- Australia

- Vessel Make

- Milkraft 60 converted timber prawn trawler

On our 60 fter we have 3 x 350gph with floats at different heights.

We also have 3 spares in parts locker.

Also, in place ready to go, just need plugging in and switch flicked are two of these that supposedly can do 1800gph

https://www.bunnings.com.au/ozito-350w-dirty-water-submersible-water-pump_p4816179

We could also divert deck wash and raw water pumps but I think if they were needed its probably time to think about stepping up into the dinghy anyway.

We also have 3 spares in parts locker.

Also, in place ready to go, just need plugging in and switch flicked are two of these that supposedly can do 1800gph

https://www.bunnings.com.au/ozito-350w-dirty-water-submersible-water-pump_p4816179

We could also divert deck wash and raw water pumps but I think if they were needed its probably time to think about stepping up into the dinghy anyway.

- Joined

- Mar 17, 2012

- Messages

- 4,279

- Location

- Australia

- Vessel Name

- Insequent

- Vessel Make

- Ocean Alexander 50 Mk I

I have 3 x 2000 gph Rule pumps. The boat has 3 partial bulkheads, and there is one pump in the lazarette, one almost mid-ship in the ER and one further forward at the low point of the bilge. Alongside the latter is a 4 gph diaphragm pump which can run dry if needed but also gets water level down to about 1/4".

I would like a high capacity pump as well but have not sourced anything as yet. Perhaps something like this pool pump, 2" outlet, which is almost 8000 gph?

https://poolandspawarehouse.com.au/speck-pro-500-pool-pump-2-0hp-500lpm-1-5kw-5y-warranty.html

I would like a high capacity pump as well but have not sourced anything as yet. Perhaps something like this pool pump, 2" outlet, which is almost 8000 gph?

https://poolandspawarehouse.com.au/speck-pro-500-pool-pump-2-0hp-500lpm-1-5kw-5y-warranty.html

Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,453

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

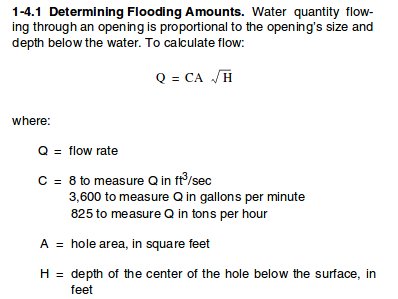

An interesting read on bilge pumps for a Navy 44'

Flooding vs bilge pumps

I know the Navy has a table for size of hole, depth of hole below water and inflow but I'm not able to find it.

Flooding vs bilge pumps

82.4 X 60 min = 4,944 gphIf a Navy 44 has a 1.5 in diameter hole at 3.5 feet below the water line (speedo thru-hull) it will experience a 82.4 gal/min influx of water.

I know the Navy has a table for size of hole, depth of hole below water and inflow but I'm not able to find it.

Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,453

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

From US Navy Salvor's Handbook

With apologies to the metric system users in the rest of the world.....

With apologies to the metric system users in the rest of the world.....

Attachments

Well, I’ve been cleaning and getting ready for another great year of boating, I have been considering adding another bilge pump, I have one now, it’s a great pump and has never let me down. How many pumps does a 65’ Boat need, two/three? There were two engine driven pumps but they are inoperable, I had a 110v pump but I found out it was junk during my bilge cleaning fun. Well let the bullets fly

I agonized a bit over this as well what made sense was looking at each compartment separately. On mine ive got 3 areas operated with bulkheads so each is tested different and separately. Engine room has the most because its got the shafts, two engines, two generators. So it gets two dc 3700gph dc on each end, one 2000gph ac, and both generator water intake can be flipped to draw water from inside as well. The mid ship gets a single 3700gph dc and the forward compartments a single 2000gph. A high water alarm in each zone, lights in the pilothouse if they turn on and a couple spares new in a box tucked away. All run on individual float switch with a manual switch as well. Total capacity was calculated from various articles linked from this forum as well as that formula above.

Just for redundancy you might want more than one.

From US Navy Salvor's Handbook

With apologies to the metric system users in the rest of the world.....

So a 10 inch hole 3 foot down would need a 200hp thrash pump running at 3000rpm with a 12 inch hose just to keep up with the inflow ?

Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,453

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

I don't know the capacity of the pump you cited but the navy calcs say the inflow will be huge so it's going to take a monster of a pump.

I have no salvage experience so I have to trust the navy's calcs. I can't imagine trying to deal with a 10 inch hole! If I bash a hole that big in my boat I hope I'm stuck on the rock I just hit and can get things under control before the tide rises.

I have no salvage experience so I have to trust the navy's calcs. I can't imagine trying to deal with a 10 inch hole! If I bash a hole that big in my boat I hope I'm stuck on the rock I just hit and can get things under control before the tide rises.

stubones99

Guru

If you have space on your prop shaft(s) between the transmission and the packing, you can add a fastflow pump that works Well both forward and reverse. All you have to do is keep the props turning and find a place to run the vessel up on shallows in the event of a major hull breach. I would want an alarm placed below the pump level so you have an alert that there is a problem.

greysailor

Senior Member

- Joined

- May 10, 2013

- Messages

- 227

- Location

- Republic of Texas - USA

- Vessel Name

- Salty

- Vessel Make

- 2005 Defever 44

Salty has 5 2000gph 12v pumps between the 3 bilge sections and the 2 open top shower sumps. However, I doubt they'll do half that capacity after factoring in discharge head. Also have a 2" 120v emergency trash pump for when Murphy shows up. High water alarms in all 3 bilge sections.

Mor be betta!

Mor be betta!

Ski in NC

Technical Guru

I built four semi water tight compartments, each has a 2000gph dc pump. Half the pumps on engine start batt, other half on on house batt. Also have a shower sump and condensate drain sump that if submerged will pump some water.

Should be able to flood any of the four compartments and still stay afloat. For a while.

On a boat with a common bilge, I would want a minimum of two pumps hopefully with different DC power source. A smaller "keep dry" pump mounted low, and a big one mounted higher up.

Should be able to flood any of the four compartments and still stay afloat. For a while.

On a boat with a common bilge, I would want a minimum of two pumps hopefully with different DC power source. A smaller "keep dry" pump mounted low, and a big one mounted higher up.

danderer

Guru

I felt pretty comfortable with my current setup: 4 pumps with a total nominal capacity of 8500 GPH on a 40' boat.

However, when changing the depth transducer this week I realized a failure of even that single small fitting would overwhelm all my pumping capacity and sink the boat.

The math is pretty straightforward. Even assuming all 4 pumps work correctly my effective pump rate would probably be 4000-5000 GPH. The transducer fitting, a 2" hole located 2' below the waterline will admit about 6700 GPH.

Absent quickly acquiring more pumping capacity or stemming the flow, the boat is going to the bottom.

That is just an example, but my takeaway is the importance of the advice above: Be ready to deal with flooding situations by limiting the ingress of water--don't just expect to rely on your pumps.

I still feel the same way about this.

boathealer

Guru

As long as you can get access to the hole, one of these

Would make the pumps job A LOT easier.

Would make the pumps job A LOT easier.

Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,453

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

This is an interesting discussion. What are the most likely flooding causes? Through hull failure, raw water cooling hose failure, shaft pulled out of the stern tube.? Using the navy calcs for my boat I am drastically 'under pumped'.

Regarding the pumps they are all 12 V DC pumps. My batteries are low in the engine room, when the batteries drown the pumps stop.

Regarding the pumps they are all 12 V DC pumps. My batteries are low in the engine room, when the batteries drown the pumps stop.

How big is the leak ? Id say the same as a length of sting.

My boat just passed insurance survey with 100% its 32 IG .

its 32 IG .

The insurance company required 2 x 2000gph pumps which it has . So wouldn't you think they have some idea of whats needed to protect there side of the policy ???.

I've seen a 3 inch hole in the bottom of a timber 40' ferry and it was uncontrollable even with a 12hp fire pump on the dock .

My boat just passed insurance survey with 100%

its 32 IG .

its 32 IG .The insurance company required 2 x 2000gph pumps which it has . So wouldn't you think they have some idea of whats needed to protect there side of the policy ???.

I've seen a 3 inch hole in the bottom of a timber 40' ferry and it was uncontrollable even with a 12hp fire pump on the dock .

Similar threads

- Replies

- 10

- Views

- 1K

- Replies

- 22

- Views

- 2K