MichaelB1969

Guru

- Joined

- Oct 15, 2016

- Messages

- 679

- Location

- USA

- Vessel Name

- Speedy Charlotte

- Vessel Make

- Beneteau Swift Trawler 44

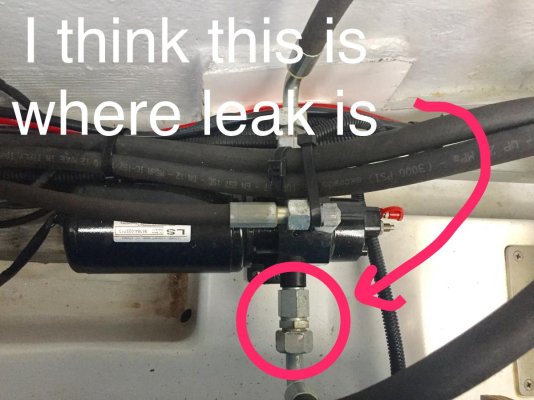

Any guidance on how to go about tightening this fitting on a Lecomble & Schmitt power unit for the autopilot? It is leaking. Seems to be 3 places to put a wrench on. Not sure what's what. Hoping it is a standard fitting that someone can decipher for me.

Thanks!

Mike

Thanks!

Mike