Pure pleasure

Senior Member

Do you run the blower all the time with a diesel I have a 48 krogen.

You probably have a fuel cooler so that the build up in the fuel temp will not be that critical. At low rpm the blower might removes some heat but at high RPM it could actually reduce the performance by increasing the engine room air depression which makes harder for the engine to get combustion air. Best to let the engine be the fan underway and let the blower manage waste heat when you stop.

You probably have a fuel cooler so that the build up in the fuel temp will not be that critical. At low rpm the blower might removes some heat but at high RPM it could actually reduce the performance by increasing the engine room air depression which makes harder for the engine to get combustion air. Best to let the engine be the fan underway and let the blower manage waste heat when you stop.

I would love to find a 12v timer switch that could be toggle on and then shut itself off after 30 minutes. I can think of a couple uses for that.

Many electronics such as inverters do not like to be exposed to high heat. . The blower is there to protect that equipment

You have an opportunity for comparative testing, by running the boat with and without the blower operating. If you do, conditions of operation will need to be as similar as you can get them to provide fair comparison.Interesting information. I have typically not run the blower on my boat. My thought was that the engine's air intake is providing a lot more air exchange than the blower does anyway. However, maybe I am wrong on that. The other issue is getting rid of the heat after shut down, something I hadn't though of either.

I have some very long runs ahead of me over the next week (12hours or so). I suppose that with the heat buildup in the fuel tanks (that flank the ER) as well as the heat soaking of the ER from a very long run, every little bit of venting could help?

Intermatic spring wound timers Time range from minutes to hours.

Buy the commercial grade (FF). The Decorator grade (FD) is price point junk.

Ted

Dave, I figured your boat probably had a Cummins and she is of about the same vintage as ours with QSB 5.9 230. I ran a well known boat yard and we were a Cummins servicing dealer. Engine room depression is more common than people realize. A diesel consumes a lot of air. If you are going to put a timer on the engine room fan, it probably needs to be set for hours, not minutes. Granted your ambient air and water are cooler than ours (83 degree water right now). To get our engine room below 100 degrees we often have to run the fan for 4-6 hours in the summer time. In the winter with 45 degree water we don't run it much at all.

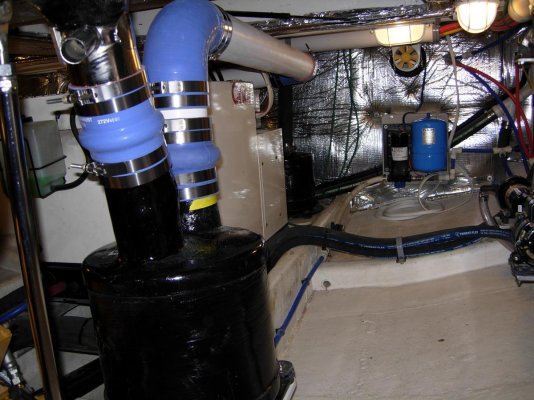

Does anyone have pictures of the fan/air pickup duct? Some fans I have seen pickup under the diesel engine, which seems out of place. (Heat Rises). And where is your discharge?