Blue Heron

Guru

Mechanic thinks this is the culprit...

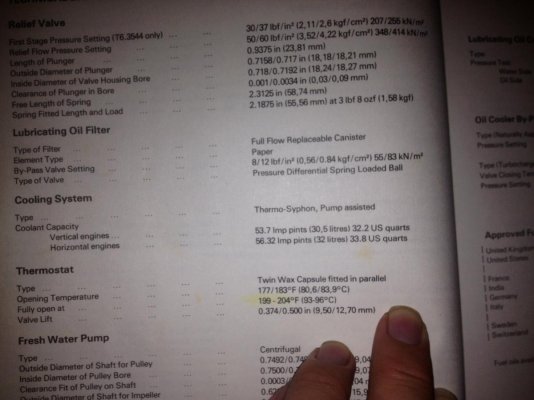

included is my Perk owners / oper manual showing the 33 quart capacity.

What isnt seen in this pic is the copper tube is completely blocked in some areas and the lower riser is severly corroded. Mech thinks a hole is present allowing the coolant to enter the exhaust and thus thats where it is going.

You can see coolant resididual in the rubber fitting at top.

I am hopeful that when the engine shut down I didnt do any damage to the Head or Gasket. We will see..

included is my Perk owners / oper manual showing the 33 quart capacity.

What isnt seen in this pic is the copper tube is completely blocked in some areas and the lower riser is severly corroded. Mech thinks a hole is present allowing the coolant to enter the exhaust and thus thats where it is going.

You can see coolant resididual in the rubber fitting at top.

I am hopeful that when the engine shut down I didnt do any damage to the Head or Gasket. We will see..

Attachments

Last edited: