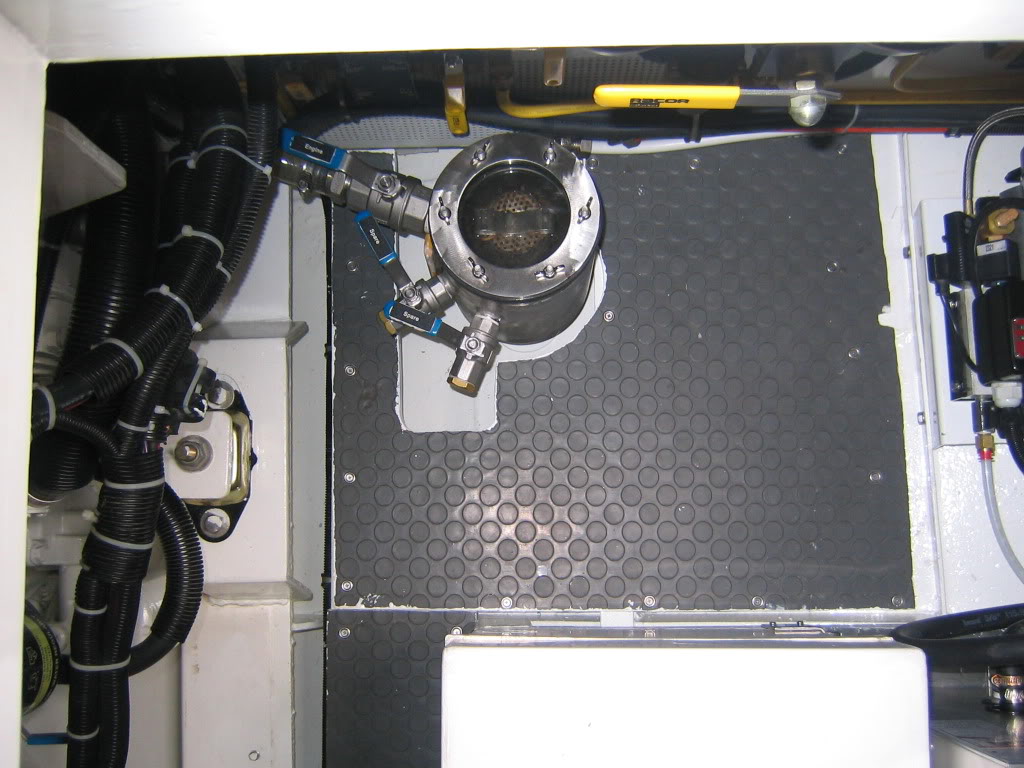

Are there any other through-hulls that you might be able to T into for the washdown pump line. eg feed to head?? We have our deckwash T'd into the watermaker feed line just after the through-hull. Since we do not make drinking water while washing the anchor/deck, no problem. If the engine feed is your only option, I would be careful the first few times you run the deckwash while operating the main engine to make sure that the deckwash pump is not starving the engine feed. I assume you will need to run the engine while washing down the anchor. FWIW if your main impeller is in decent shape, I would guess it is more likely the engine will starve the deckwash.