LeoKa

Guru

- Joined

- Apr 15, 2017

- Messages

- 1,150

- Location

- USA

- Vessel Name

- Ironsides

- Vessel Make

- 54' Bruce Roberts steel sailboat hull, coastal LRC, 220HP CAT 3306.

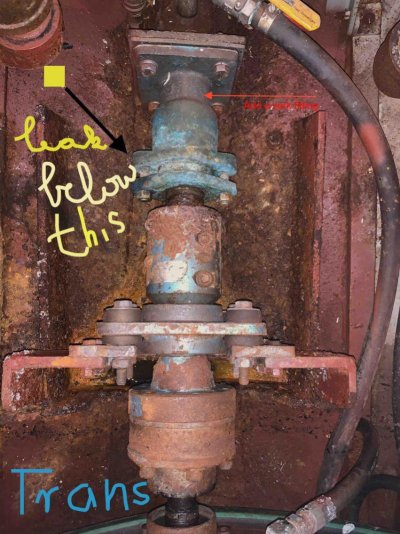

Can someone guide me, how to eliminate the dripping between the trans and shaft connection. It is a slow dripping, but it accumulates and the rust is active all the time. I pump the water out frequently, but it will never be dry.

See attached photos.

Thanks.

See attached photos.

Thanks.