Olebird

Senior Member

- Joined

- Aug 23, 2019

- Messages

- 413

- Location

- USA

- Vessel Name

- StarLite

- Vessel Make

- Mainship 30 Pilot II - 2003

New to me 2003 Pilot II needs some TLC and other things. Have a long list of items to check, improve, repair etc as we make this boat our own. Very interested in what other nu owners have done to confirm 15 yr old boats seaworthiness & improve on MS's already excellent build.

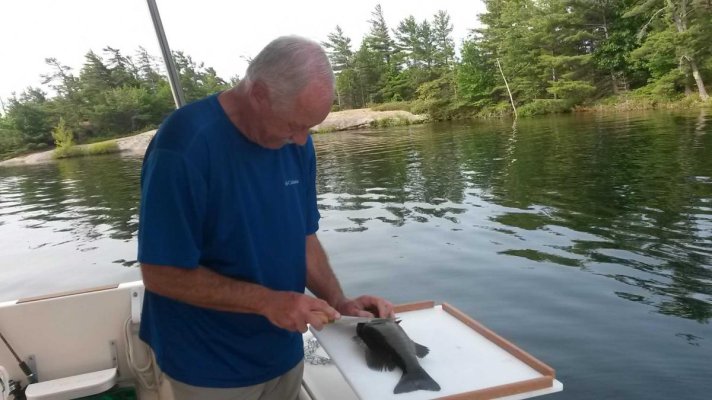

Has anyone added Rod Holders to the Pilots gunnels. Sure hate to clutter up the MS beautifully clean decks & gunnels but need to use holders for rods and other things?

Has anyone added Rod Holders to the Pilots gunnels. Sure hate to clutter up the MS beautifully clean decks & gunnels but need to use holders for rods and other things?

Attachments

Last edited: