Derik

Senior Member

- Joined

- Aug 21, 2018

- Messages

- 160

- Location

- United States

- Vessel Name

- Pearl Grace

- Vessel Make

- Marine Trader/Sun Deck 44

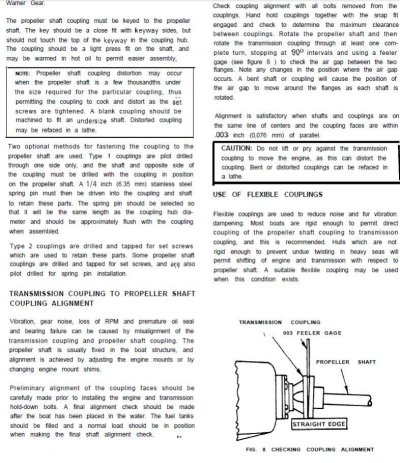

I have the Borg Warner 72c's and was getting ready to do an oil change. Reading through the Borg Warner Velvet drive Owners Manual it mentions a propeller shaft coupling shaft alignment and recommends it be done after a haul out.

It seems fairly straight forward with a feeler gauge, is it something you guys here do routinely after a haul out?

It seems fairly straight forward with a feeler gauge, is it something you guys here do routinely after a haul out?