Hi,

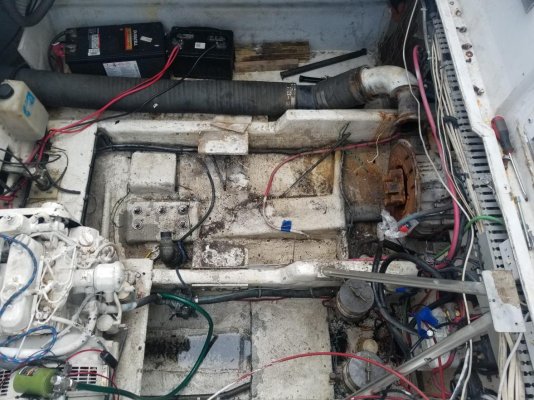

I've got a 40 ft Mainship Sedan Bridge and need to pull the port engine, Cummings 6BTA, that is mated to a Velvet drive, ZF 631IV (HSW 630V1 HSW). This is the type of V drive in which the shaft passes through transmission and is bolted in the front.

Typically, you need to pull the engine and transmission together, as disconnecting at the bell housing is problematic. There is about 6" of shaft that would need to come out, but the engine mounts make it difficult to pull it out. It would also screw up the shaft alignment, where as pulling the engine and transmission together just requires getting it back in trhe existing mounts.

Pulling the engine and transmission together requires backing the shaft back around 13" to clear it from the transmission. I dove on the prop and rudder, and there is only about 7" of play for the shaft to back out. The spec for this transmission show I need 13". Even if I pull the prop, I still only have about 7" of play.

What do I do ? I cant pull the rudder, because this need to be done in the water without hauling the boat.

Help !

I've got a 40 ft Mainship Sedan Bridge and need to pull the port engine, Cummings 6BTA, that is mated to a Velvet drive, ZF 631IV (HSW 630V1 HSW). This is the type of V drive in which the shaft passes through transmission and is bolted in the front.

Typically, you need to pull the engine and transmission together, as disconnecting at the bell housing is problematic. There is about 6" of shaft that would need to come out, but the engine mounts make it difficult to pull it out. It would also screw up the shaft alignment, where as pulling the engine and transmission together just requires getting it back in trhe existing mounts.

Pulling the engine and transmission together requires backing the shaft back around 13" to clear it from the transmission. I dove on the prop and rudder, and there is only about 7" of play for the shaft to back out. The spec for this transmission show I need 13". Even if I pull the prop, I still only have about 7" of play.

What do I do ? I cant pull the rudder, because this need to be done in the water without hauling the boat.

Help !