So, this discussion strikes me as a little curious.

It is generally true that when engineers see the world, they see it through the lens of tolerances and probability densities, and when others see the world, this might not be the case. But, this doesn't mean that a typical operator or maintainer can't understand how things work.

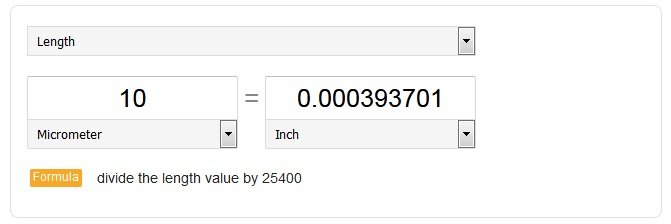

And, I certainly don't think one needs beta ratios to understand fuel filtering enough to make an informed decision about what one needs. Percentages are easier for most people to grok. Starting with beta ratios is like asking the average person to measure the kiddie pool in fathoms vs inches, just because some commercial skipper does. Why bother? Inches (or centimeters, for my metric friends) communicate the same information in a more accessible way. I think.

Last whence I checked, Racor's filters for my filters were rated (nominal) as follows:

-- 2 micron filters: 98% efficiency

-- 10 micron filters: 95% efficiency

-- 30 micron filters: 90% efficiency.

This means, for example, that when tested under standard conditions in the standard way, the 2 micron filter retained at least 98% of the particles 2 microns or larger -- letting no more than 2% pass back out.

I think at one point I chased down the Perkins spec for the secondary filters for my Perkins 6.354MGT and 6.354(M) motors and I found it to be

-- 99% efficiency @ 14 micron (SAE).

Assuming the folks in Peterborough, England knew what they were doing, and I suspect they did, I don't need a primary (or secondary) filter rated "better" than that for the fuel injection system to enjoy a normal life with normal maintenance.

In a 2-stage filtration system, the primary fuel filter doesn't normally provide much protection to the fuel injection system. It primarily protects the secondary fuel filter from being clogged by the "big chunks" and failing prematurely before scheduled replacement, enabling the secondary fuel filter to protect the injection system.

But, what if we were talking about a new common rail fuel system instead of my venerable Perkins 6.354s? Well, then, that would be a totally different case. Those things can be crazy high pressure with really tight tolerances. They probably have N-ary fuel filter rated to 98-99+% at 2 or 3 microns. And, depending on the application, they might have three stage filtering -- 30 micron to protect a 10 micron to protect the 2-3 micron filter to protect the injection system.

But back to Racor's numbers. I forget (if I ever knew) if they are ratings under the applicable ISO (Europe) or SAE (North America) process. It matters to some engineers, sometimes. But, it doesn't matter to me. The 2ndary fuel filter is just to get the big chunks out to extend the longevity of my primary filter, remember?

I don't happen to know the applicable SAE or ISO or ANSI procedures well enough to speculate about how they are testing. But, how the test is conducted matters a lot. For example, one can pass a set of contaminants through the filter in a one way flow (single pass) -- or continuously recycle the filtered fluid (multipass), adding more contaminants with each pass to make up for what has filtered out.

The multi-pass approach is more interesting, I think, because the missed particles get passed through again -- and can be misses again. A round ball may pass through each time, but a rod-shaped containment may be hit-or-miss depending upon orientation and tumble. The other thing that is interesting -- way more interesting, I think -- is that as the filter clogs up, the pathways become smaller, and it filters more efficiently. By taking measurements over time, this performance curve can be drawn and visualized, perhaps along side a curve showing changes in pressure over time as a result of the increasingly clogged filter.

Don't hold me to this, but I think the fuel filter ratings we see are often ISO or SAE ratings that are single-pass. I suspect manufacturers have multi-pass curves, but that may be proprietary or I just haven't seen it.

One important thing to note about the applicable tests, whether SAE or ISO or ANSI, is that they test under specific, controlled lab conditions. The real world has a funny way of making such numbers look pretty. As a for example, I don't think either of the applicable standards tests under vibration (but, I could be wrong). But, just like trying to get a small part out of a container with a slightly less small opening -- the more one shakes the more likely it is that one will get the part into an orientation that can fit through the opening. We could also consider actual fuel pressures and tolerances, etc.

The point is, even given a rigorous standardized multipass nominal rating, I'd expect at least some loss of efficiency in a real world engine vs lab conditions.

Also in the real world, although as a filter clogs it gets more efficient, it also gets harder to move fuel through. At least until the resulting pressure difference opens a bypass (if present, unlikely), eliminating filtering or stalls an engine by starvation (more likely).

The upshot is that, although there are different standardized and proprietary testing methods, the micron rating is a pretty darn good measure. And, none of these measures are absolute.

And, as for those beta ratios, c'mon. Talking about efficiency that way instead of as a percentage is just changing to units less familiar to many. Beta ratios are just a count of the particles on the input side of the filter to those on the output side of the filter. So, for example, if we want to talk about the ratio at 5 microns, we'd have a ratio of the concentration (count of particles per volume) of particles greater than 5 microns on the input side to those on the output side.

-- B5 = {count of particles > 5 microns in some volume of fluid on the input side}

----------------------------------------------------------------------------------

{count of particles > 5 microns in some volume of fluid on the output side}

So, in other words, for any arbitrary micron rating, one can just convert from a percentage to a beta ratio like this:

-- Given a % efficiency = x%

-- Express it as a fraction: x/100

-- This means that if 100 particles were at the input, (100-x) particles would be at the output

-- B = 100/(100-x)

And, we can go the other way, too:

-- Given a B, as above

-- We want an x, as above

-- Take our formula from above: B = 100/(100-x)

-- Do algebra to isolate x: x = 100*(B-1)/B

-- So the filter is x% efficient

The upshot is, I understand beta ratios -- and think that it made sense to start with percentages. I'll let the reader be the judge.

If you'd ask me what is interesting about "Multi-Pass Beta Ratio (MPBR)" testing, it isn't that the units is a beta ratio vs percentage efficiency. It is that by taking periodic measurements as the filter loads over time, the multi-pass regiment provides a nice way to plot curves of filter performance over time. And, those curves can be interesting. I think.

Regardless, back to the POs question: What micron rating should be used on the primary filters? Generally speaking, nothing smaller than the Nth stage fuel filter. From the pictures, it looks like it is a 1970s or early 1980s trawler. Maybe a classic for Lehman? It probably has a 95% @ 10 micron (SAE) filter. Wild guessing. So, nothing finer grain than that is needed. And a 30 micron secondary filter is probably very appropriate to "take the big chunks out" to keep its life acceptable for the prescribed service lifetime.

Would it make sense to use a finer grained primary filter than 10 microns? Probably not or Ford (or American Diesel or Bomac) would have spec'd one for the primary. Could one sensibly choose to use 10 micron 2ndary filters? Sure. They'd extend the life of the primary filter -- at the expense of the life of the 2ndary filter. If the fuel is good, it might be a good trade for convenience. If the fuel is not so good -- it might clog up too soon and create an unfortunate surprise underway. And, that is the risk of filtering too finely on the primary -- get some unexpected junk, and it'll be clogged up when it might not need to be.

I mentioned that my Perkins engines call for a 95% @ 14 micron primary filter. What do I use as a 2ndary filter? I usually use 10 microns. Won't hurt nothing. Except when I goof and order 30s -- in which case I happily use those. Won't hurt nothing, either.

Reminds me of my old engineering methodology professor. He liked to ask (and answer), "What do you call something over spec? Waste." He was a civil engineer and also liked to say, "Any damn fool can pour enough concrete to build a bridge. It takes an engineer to make it safe and cheap."

I guess what this whole long note comes down to is that I think the original poster's question was a very reasonable one. And, yes, I, personally, think a 20 or 30 micron secondary will catch everything that needs to be caught for a 10 micron primary.

Of course, I also don't think that there is likely to be much of a difference in price, if any. And, I don't think with decent fuel one should be clogging 10 micron filters really fast. And, if you are, I hope you have many spare 2ndaries. So, as I said, I prefer to go with the 10s, myself (even with a 95% @ 14 micron primary filter manufacturer's spec). So, with all due respect to my old prof, I'm not seeing much waste in this one, within reason, either way.

My thoughts -- for whatever they are worth.