Full disclosure, I’ve been aware that I’ve had both window leakage and knew the wood under the wallpaper was soft for about 3 years now and progressing. On Saturday, this projects number finally came into rotation.

Peeling back the wallpaper, eeewwwwwwww. Multi master scraper and the really wet stuff is out. This was plywood bonded to a thin layer of glass then gel coat on the outside. I don’t want to use the scraper as I get towards good wood as I’m afraid I’ll upset the gelcoat if I get too aggressive. So I think next week I’ll “sand” the rest of the wood out with a rough flat carbide blade on the multi master.

If anyone can think of a better method, feel free to suggest.

The window will have to come out and runs about 7 feet into the aft cabin. Some investigation suggests this is the only bad spot.

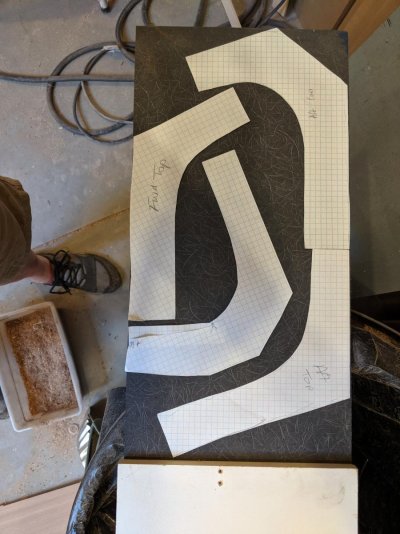

Also, stopped by Edensaw and found some nice Myrtlewood. When the nasty part gets done, the Myrtle will become the countertop in this head.

Let the winter project list begin!

Peeling back the wallpaper, eeewwwwwwww. Multi master scraper and the really wet stuff is out. This was plywood bonded to a thin layer of glass then gel coat on the outside. I don’t want to use the scraper as I get towards good wood as I’m afraid I’ll upset the gelcoat if I get too aggressive. So I think next week I’ll “sand” the rest of the wood out with a rough flat carbide blade on the multi master.

If anyone can think of a better method, feel free to suggest.

The window will have to come out and runs about 7 feet into the aft cabin. Some investigation suggests this is the only bad spot.

Also, stopped by Edensaw and found some nice Myrtlewood. When the nasty part gets done, the Myrtle will become the countertop in this head.

Let the winter project list begin!