AZ2Loop

Senior Member

I am replacing waste lines and need advice. Toilets are Jabsco 37010 electric flush. Most would say to replace both with Raritan Elegance, but with so many other updates going on that is not in the budget.

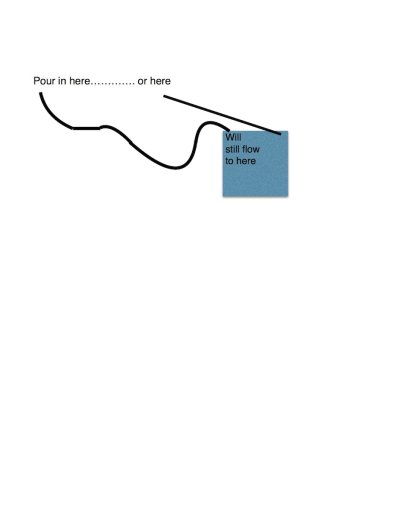

Short version of my question: Am I better off with either option A (2 climbs in elevation) or option B (only 1 climb in elevation, but about 10 feet away from the pump)?

Route Option A: run waste hose up about 20" about a foot after it leaves the toilet/pump/motor to very quickly reach highest elevation into either a Y-valve (if I keep the direct discharge option) or a vented loop, and then hose would drop down about 2 feet in elevation to get under the companionway flooring, then go about a 10 foot level run to get through a bulkhead. Then (and here is the trouble), it needs to climb about 18" back up in elevation to get to the holding tank inlet. So, that is one climb in elevation near the pump up about 20", then after dropping down lower, another climb of about 18" to get to the holding tank (2 "rises" is what bothers me) OR

Route Option B: Not climb in elevation anywhere near the pump. Just run it from the toilet, then down under the companionway for the 10 feet level run, then make the only climb in elevation take place after the bulkhead near the holding tank. The rise in elevation could then be about 2 feet or 18", into a vented loop or Y valve (if I choose to keep the direct discharge as an option), then into the tank. I like having only one rise in elevation. What bothers me about option B is while there is only 1 rise in elevation, it takes place about 10 from the motor on the electric toilet. Not sure if this is good or trouble/clogging waiting to happen.

More details in next post if you care to know more. I was trying to keep this as short as possible. Thanks for any thoughts.

Short version of my question: Am I better off with either option A (2 climbs in elevation) or option B (only 1 climb in elevation, but about 10 feet away from the pump)?

Route Option A: run waste hose up about 20" about a foot after it leaves the toilet/pump/motor to very quickly reach highest elevation into either a Y-valve (if I keep the direct discharge option) or a vented loop, and then hose would drop down about 2 feet in elevation to get under the companionway flooring, then go about a 10 foot level run to get through a bulkhead. Then (and here is the trouble), it needs to climb about 18" back up in elevation to get to the holding tank inlet. So, that is one climb in elevation near the pump up about 20", then after dropping down lower, another climb of about 18" to get to the holding tank (2 "rises" is what bothers me) OR

Route Option B: Not climb in elevation anywhere near the pump. Just run it from the toilet, then down under the companionway for the 10 feet level run, then make the only climb in elevation take place after the bulkhead near the holding tank. The rise in elevation could then be about 2 feet or 18", into a vented loop or Y valve (if I choose to keep the direct discharge as an option), then into the tank. I like having only one rise in elevation. What bothers me about option B is while there is only 1 rise in elevation, it takes place about 10 from the motor on the electric toilet. Not sure if this is good or trouble/clogging waiting to happen.

More details in next post if you care to know more. I was trying to keep this as short as possible. Thanks for any thoughts.

Last edited: