One of my pumps died so I'll replace it with a slightly larger one no big deal

I started researching how many Gph total should I have on a 42

Builder provided a manual 11gpm drawing from midship under batteries between engines operated by mounted handle in cockpit.

a 3gpm (which I'm replacing with an 8gpm ) this draws from midship also forward also drains shower. This is on a float switch

Also another 6gpm under the companion way

"The bilge pump system is not designed to provide buoyancy to the boat in case of damage.-The bilge pump system is designed to drive out the water being either sea spray or leaks but absolutely not the water coming through a hole in the hull, this hole being the result of a damage"

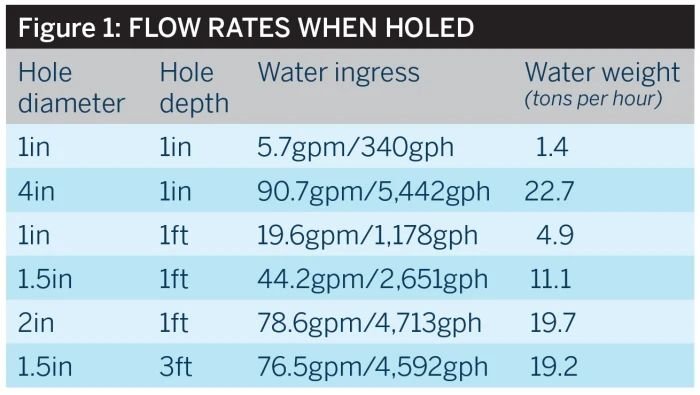

So I was going to add one or two pumps totaling 4,000 gph, but if that much water in coming in aren't the batteries going to get submerged and stop those pumps?

So I looked at the manual 30 Gpm Whale or Edson with the big handles, but who can keep up that physical work for hours on end until the leak can get slowed or help arrives.

This option looks better then adding two 12v pumps perhaps

stop/slow the leak

NERF footballs are very soft closed cell foam toy football

Great stuff foam

Truplug

soft wood plugs

toilet bowl wax

add your fixes.........

Then last resort life raft.............

I started researching how many Gph total should I have on a 42

Builder provided a manual 11gpm drawing from midship under batteries between engines operated by mounted handle in cockpit.

a 3gpm (which I'm replacing with an 8gpm ) this draws from midship also forward also drains shower. This is on a float switch

Also another 6gpm under the companion way

"The bilge pump system is not designed to provide buoyancy to the boat in case of damage.-The bilge pump system is designed to drive out the water being either sea spray or leaks but absolutely not the water coming through a hole in the hull, this hole being the result of a damage"

So I was going to add one or two pumps totaling 4,000 gph, but if that much water in coming in aren't the batteries going to get submerged and stop those pumps?

So I looked at the manual 30 Gpm Whale or Edson with the big handles, but who can keep up that physical work for hours on end until the leak can get slowed or help arrives.

This option looks better then adding two 12v pumps perhaps

stop/slow the leak

NERF footballs are very soft closed cell foam toy football

Great stuff foam

Truplug

soft wood plugs

toilet bowl wax

add your fixes.........

Then last resort life raft.............